- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In the rapidly evolving landscape of industrial machinery, the demand for reliable Hydraulic Pump Repair services has surged, driven by a burgeoning global manufacturing sector. According to a recent report by Research and Markets, the hydraulic pump market is projected to reach $12 billion by 2026, with a significant portion attributed to the need for efficient repair and maintenance solutions. Proudly emerging from China's top-tier factories, our Hydraulic Pump Repair services embody precision engineering and superior craftsmanship, establishing a strong foothold in global markets. As industries seek to enhance productivity and minimize downtime, the trust in Chinese manufacturing continues to rise, making it a pivotal player in fulfilling the world's hydraulic repair needs. Through innovation and commitment, we are dedicated to offering solutions that meet international standards and cater to the diverse requirements of clients around the globe.

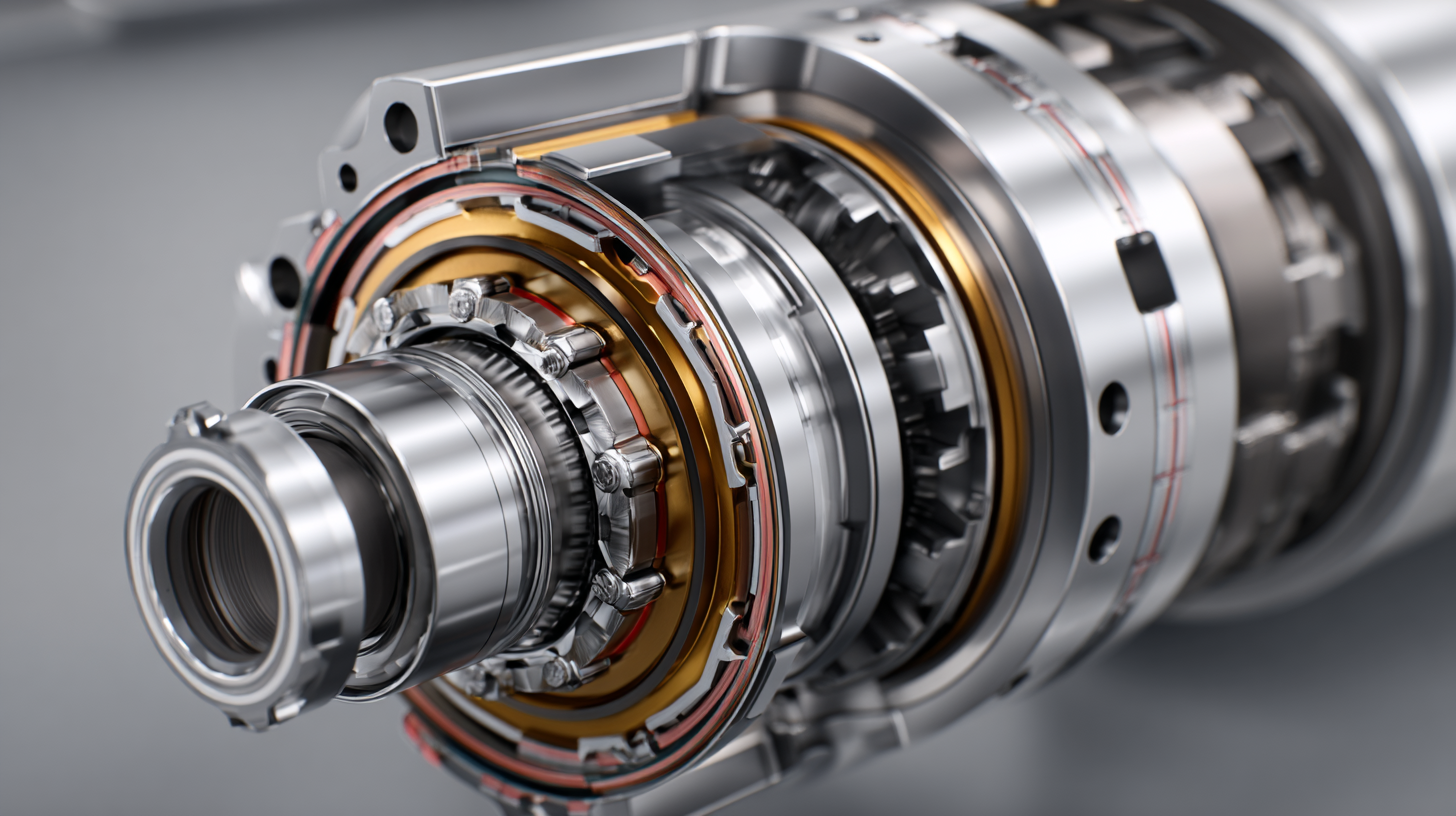

The evolution of hydraulic pump technology in China has marked a significant transformation, reflecting the country’s rapid advancements in engineering and manufacturing. Over the recent years, China has emerged as a global leader in the design and production of hydraulic piston pumps, essential components in various industrial applications, particularly in aviation. These pumps are designed with a focus on high reliability to ensure safety and performance in critical systems. As the demand for sophisticated machinery increases globally, China's hydraulic technology continues to innovate and adapt.

Tips for ensuring reliability in hydraulic pumps include regular maintenance and monitoring. Implementing a predictive maintenance schedule can help identify potential issues before they lead to failure. Additionally, investing in high-quality materials and components during the manufacturing process enhances the overall durability of the pumps.

Moreover, advances in electro-hydraulic systems are paving the way for more efficient and responsive machinery. These systems not only improve performance but also contribute to energy savings, which is vital in today’s environmentally conscious market. By embracing new technologies, manufacturers can better meet the needs of their clients and maintain a competitive edge in the global market.

In the rapidly evolving global market for hydraulic pump repair, maintaining high-quality standards is paramount. China has emerged as a significant player, not only meeting but often exceeding international quality benchmarks. With advanced manufacturing technologies and rigorous quality control processes, Chinese companies are redefining the norms for hydraulic pump repair. This attention to detail ensures that the repaired pumps operate efficiently, reducing downtime for clients across various industries.

Understanding the global perspective on quality standards is essential for success in this competitive landscape. Different regions have varying requirements and certifications, which necessitates a deep understanding of customer expectations. To cater to global markets, Chinese manufacturers implement comprehensive training programs for technicians and adopt best practices from around the world. By blending local expertise with international standards, these companies are not just repairing hydraulic pumps; they are enhancing overall operational performance, establishing their reputation as leaders in quality and reliability on the global stage.

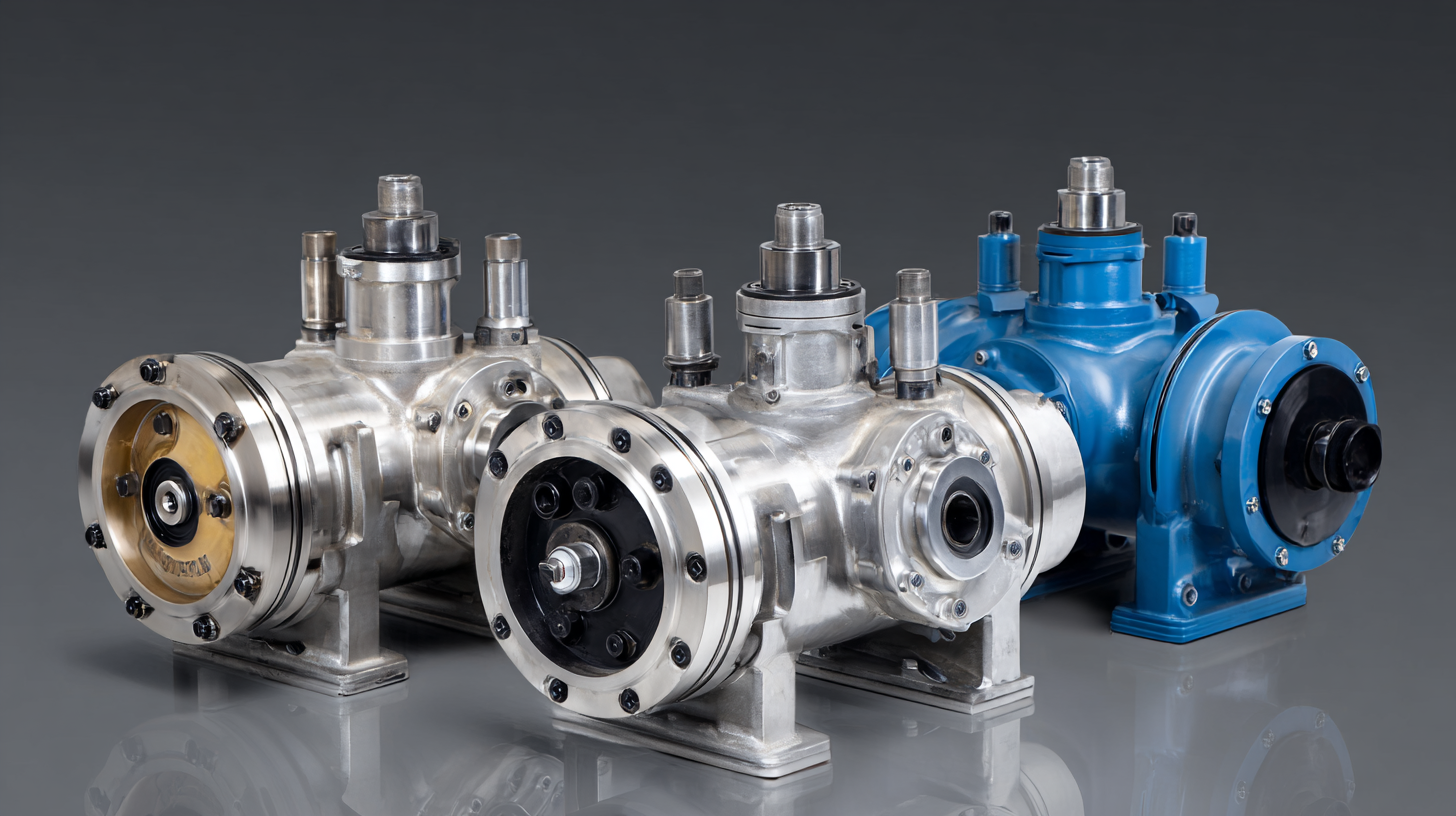

Chinese hydraulic pump manufacturers are making significant strides in the global market by offering innovative solutions that cater to diverse industrial needs. With a focus on advanced technology and efficient production processes, these manufacturers are able to deliver high-quality hydraulic pumps that not only meet but often exceed international standards. The incorporation of cutting-edge technology in design and manufacturing ensures that these pumps offer reliable performance and longevity, essential for various applications across sectors like construction, agriculture, and manufacturing.

In addition to technological advancements, Chinese manufacturers are placing a strong emphasis on customization and customer service. They understand that different industries have unique requirements, so they work closely with clients to develop tailored solutions that enhance operational efficiency and reduce downtime. By investing in research and development, Chinese hydraulic pump companies are continually improving their product lines, propelling their offerings to a world-class level. This commitment to innovation and client satisfaction is transforming perceptions of Chinese manufacturing, establishing the country as a vital player in the global hydraulic pump industry.

In recent years, Chinese manufacturers have increasingly made their mark in the global hydraulic pump industry, showcasing their commitment to quality and innovation. One standout success story is the expansion of a leading Chinese hydraulic pump manufacturer into North America and Europe. By leveraging advanced production techniques and stringent quality control measures, these companies have earned the trust of international clients, resulting in significant growth in exports. Clients in various sectors, from construction to agriculture, have reported enhanced operational efficiency and cost-effectiveness with their imported hydraulic pumps.

Additionally, the demand for Chinese hydraulic pumps in emerging markets is on the rise. Countries in Southeast Asia and Africa are recognizing the value of reliable and affordable hydraulic solutions for their infrastructure projects. Chinese firms have adapted their strategies by establishing local partnerships and providing after-sales support, further solidifying their reputation as a dependable supplier. These efforts highlight China's ability to not only manufacture but also innovate on a global scale, proving that high-quality hydraulic pump repair and production can indeed lead the market.

| Market | Export Volume (Units) | Growth Rate (%) | Key Features | Customer Satisfaction (%) |

|---|---|---|---|---|

| North America | 15000 | 15 | High efficiency, low maintenance | 92 |

| Europe | 20000 | 10 | Compact design, energy saving | 90 |

| Asia-Pacific | 18000 | 12 | Durable materials, customizable | 88 |

| Middle East | 12000 | 18 | Corrosion-resistant, high output | 85 |

| South America | 9000 | 20 | Affordable pricing, reliable service | 80 |

The hydraulic pump repair industry is undergoing significant transformations, driven by technological advancements and shifting market demands. According to a report by MarketsandMarkets, the hydraulic pumps market is expected to grow from USD 13.64 billion in 2020 to USD 19.93 billion by 2025, highlighting an annual growth rate of 7.9%. This growth creates both opportunities and challenges for repair service providers, particularly in regions like China, which is emerging as a key player in the global market.

One of the notable trends is the increasing integration of IoT and AI in hydraulic pump systems. These technologies not only enhance the efficiency and longevity of pumps but also streamline the diagnostic and repair processes. A study by ResearchAndMarkets indicates that predictive maintenance, driven by data analytics, could reduce downtime by up to 30%, presenting a substantial cost-saving proposition for companies. However, the challenge lies in keeping up with these rapid technological changes. Repair workshops must invest in skilled labor and advanced tools to remain competitive, particularly as more manufacturers look to outsource their repair services to countries like China, renowned for its cost-effective and high-quality solutions.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy