- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In today's globalization landscape, the hydraulic pump parts industry is experiencing significant growth, driven by increasing demand across various sectors such as construction, agriculture, and manufacturing. According to a recent report by MarketsandMarkets, the global hydraulic pump market is projected to reach $56.09 billion by 2025, fueled by advancements in technology and the rising need for efficient power transmission solutions. However, navigating the complexities of international trade for hydraulic pump parts necessitates a comprehensive understanding of essential certifications and standards. Compliance with industry regulations not only ensures product quality and safety but also enhances market competitiveness. This blog will explore seven crucial certifications that play a vital role in facilitating the importation of hydraulic pump parts, unlocking lucrative opportunities in the global marketplace.

In the industrial sector, hydraulic pumps are critical components that drive efficiency and productivity. The effective operation of one such hydraulic pump can significantly affect the overall performance of machinery. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to grow from USD 43.2 billion in 2021 to USD 55.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.1%. This surge underscores the importance of importing high-quality hydraulic pump parts that meet stringent certification standards.

Case studies from renowned manufacturers reveal that the use of certified hydraulic pump components leads to enhanced reliability and reduced downtimes. For instance, a leading OEM reported a 30% increase in operational efficiency after switching to certified hydraulic pumps and parts. In another significant example, an industrial plant that implemented ISO 9001 certified parts noted a 15% reduction in maintenance costs over three years. Such data illustrate not only the necessity of rigorous certifications but also their direct impact on industrial performance and profitability in hydraulic applications.

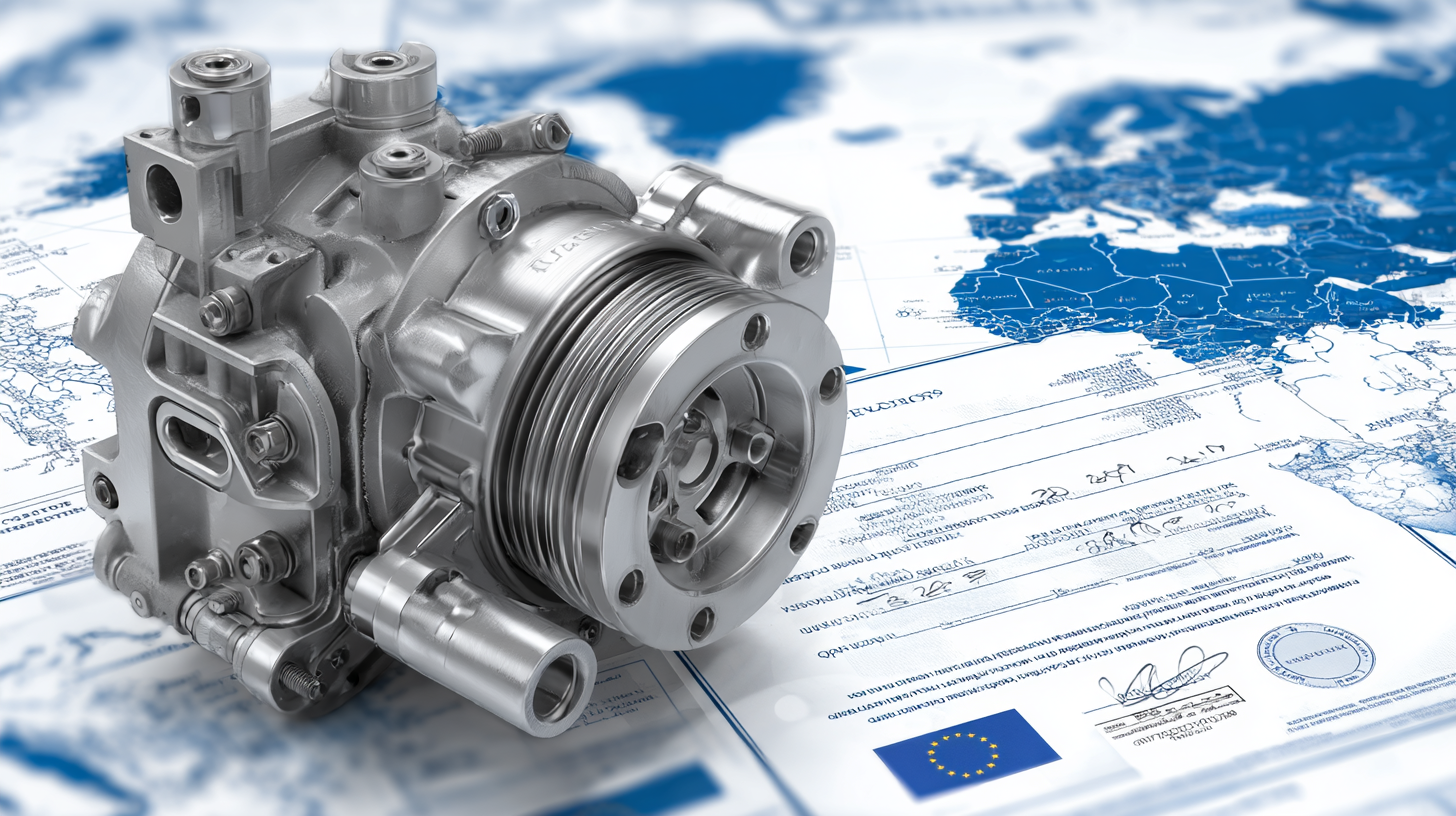

In today’s interconnected world, certifications play a pivotal role in global trade, especially for industries reliant on high-quality components such as hydraulic pumps. According to a report by the International Trade Administration, about 80% of manufacturers highlight certification as a critical factor in their purchasing decisions. This underscores the importance of ensuring that all imported hydraulic pump parts meet stringent quality and safety standards, thereby protecting both manufacturers and end-users from subpar products.

Certifications, such as ISO 9001 for quality management systems and CE marking for compliance with European standards, serve as essential assurances that components will perform reliably under pressure. A survey by the Global Trade and Compliance Forum revealed that companies with certified supply chains are 30% more likely to achieve operational efficiency and reduce compliance risks. As the demand for hydraulic systems continues to rise—projected to grow at a CAGR of 5.1% in the next five years—ensuring that critical components are certified not only meets legal requirements but also enhances the marketability and trustworthiness of products in competitive markets.

When importing hydraulic pump components, understanding the essential certifications is crucial to ensure product quality, safety, and compliance with international standards. Key certifications, such as ISO 9001, indicate that a manufacturer employs a quality management system that meets rigorous requirements. This is vital for maintaining reliability in hydraulic operations where precision is key. Additionally, certifications like CE marking can showcase that the products meet European health, safety, and environmental protection standards, thus broadening your market reach.

Tip: Always verify the validity of these certifications directly from the issuing bodies. This ensures you are importing parts from reputable suppliers who adhere to quality standards. Another important certification to consider is the API Spec 7K for drilling equipment, which includes hydraulic components, ensuring they are built for the demanding conditions of the oil and gas industry.

Moreover, certifications such as UL and CSA provide assurance on electrical safety for hydraulic pumps that integrate electronic controls. Having these certifications not only enhances credibility but also minimizes liability risks.

Tip: Engage with your suppliers early on to discuss their certification statuses and ask for documentation. This proactive approach can prevent potential compliance issues down the line, ensuring that you receive hydraulic pump components that meet your operational needs effectively.

| Certification Name | Issuing Body | Purpose | Regions Valid | Validity Period |

|---|---|---|---|---|

| ISO 9001 | International Organization for Standardization | Quality management systems | Global | 3 years |

| CE Marking | European Conformity | Product safety for European markets | European Union | Varies by product |

| ISO 14001 | International Organization for Standardization | Environmental management systems | Global | 3 years |

| UL Certification | Underwriters Laboratories | Safety certification for electrical products | North America | Varies by product |

| RoHS Compliance | European Union | Restriction of hazardous substances in electronics | European Union | Ongoing |

| CSA Certification | Canadian Standards Association | Product safety certification in Canada | Canada | Varies by product |

| API Certification | American Petroleum Institute | Standards for petroleum and natural gas industry | Global | 3 years |

Obtaining the necessary certifications for importing hydraulic pump parts is crucial for ensuring compliance with

international trade regulations and maintaining product quality. The first step in this process involves understanding the specific certifications

required by your target market. For instance, the ISO 9001 certification, which focuses on quality management systems,

is essential for manufacturers aiming to export hydraulic components globally. According to industry reports, over 70%

of companies reported improved efficiency and customer satisfaction after obtaining this certification.

Once you've identified the necessary certifications, the next step is to navigate the application process effectively. This typically includes

preparing the required documentation, such as technical specifications, testing results, and compliance statements. For example, relevant countries may

also require CE marking or UL certification to ensure that products meet safety and

performance standards. Leveraging a detailed checklist, akin to those used in e-commerce to launch a store, can help streamline the process. It's

important to stay informed about local regulations and industry standards, as these can change and impact your certification path. Keeping abreast of

these factors will ultimately facilitate smoother importing and enhance your competitive edge in the global market.

Once you've identified the necessary certifications, the next step is to navigate the application process effectively. This typically includes

preparing the required documentation, such as technical specifications, testing results, and compliance statements. For example, relevant countries may

also require CE marking or UL certification to ensure that products meet safety and

performance standards. Leveraging a detailed checklist, akin to those used in e-commerce to launch a store, can help streamline the process. It's

important to stay informed about local regulations and industry standards, as these can change and impact your certification path. Keeping abreast of

these factors will ultimately facilitate smoother importing and enhance your competitive edge in the global market.

In the realm of global trade, ensuring compliance through proper certifications is crucial for the success of importing hydraulic pump parts. According to a report by the International Trade Administration, over 80% of businesses attribute trade barriers, including regulatory compliance, to significant losses in potential revenue. The importance of certifications cannot be overstated; they not only assure quality but also enhance marketability. For example, compliance with ISO 9001 standards can lead to a 30% increase in customer satisfaction and retention, as verified by the Journal of Quality Management.

Moreover, proper certifications help mitigate risks associated with product liability and compliance with environmental regulations. Data from the World Customs Organization reveals that more than 50% of companies face delayed shipments due to non-compliance with import regulations. This can be detrimental, especially in sectors like hydraulic pump manufacturing, where precision and reliability are paramount. Ensuring that all hydraulic parts meet certifications like CE, UL, or ASME can streamline the import process and secure a competitive edge in a crowded marketplace, as highlighted in a recent industry analysis by Market Research Future.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy