- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

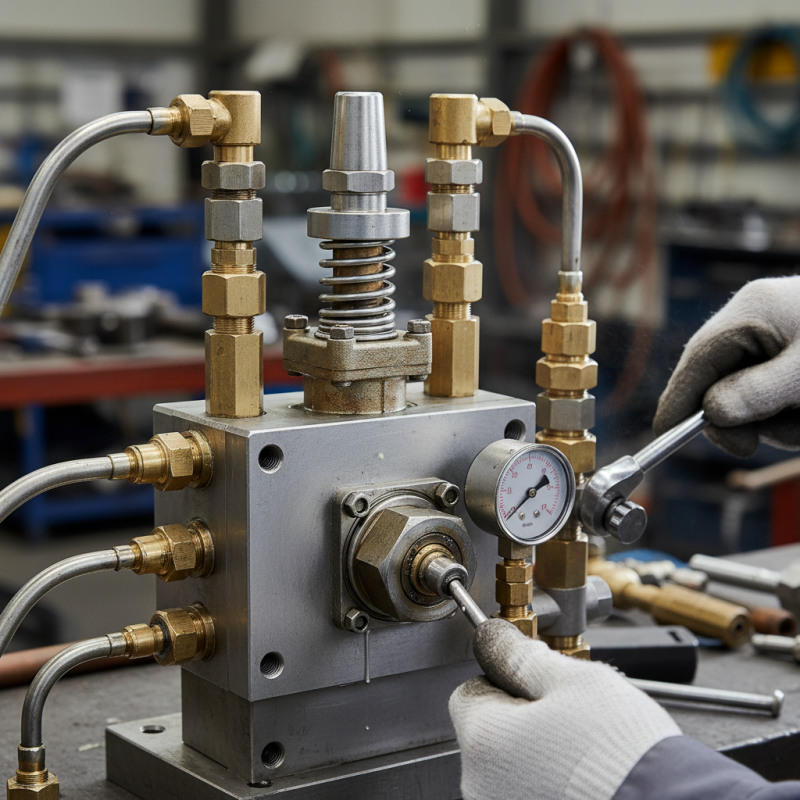

In hydraulic systems, the Overflow Valve Block plays a critical role. It regulates pressure and prevents damage. Issues with the Overflow Valve Block can lead to system failures and inefficiencies. Identifying these problems early is vital for smooth operations.

Common signs of Overflow Valve Block issues include abnormal noises and unexplained pressure drops. These symptoms may seem minor but indicate deeper problems. Operators must stay vigilant and address these warnings promptly. Neglecting them can escalate maintenance costs and downtime.

Troubleshooting the Overflow Valve Block requires careful examination. Visual inspections can reveal signs of wear. Testing the pressure settings and flow rates may uncover hidden faults. Every step in this process is essential. Mistakes can lead to further complications. Learning to manage these issues will improve system reliability and enhance operational efficiency.

Identifying symptoms of an overflow valve block is crucial for effective troubleshooting. Watch for unusual noises. A hissing or whining sound often indicates pressure issues. Additionally, check for leaks around the valve. Any fluid escaping is a clear sign of malfunction. Look for inconsistent pressure readings as well. If the pressure fluctuates unexpectedly, this can point to a blockage.

Another symptom to be aware of is system performance issues. If machinery operates sluggishly or fails to start, the overflow valve may be clogged. Examine the response time of the system. A delay can indicate restricted flow. It's essential to observe your equipment regularly. Small changes can signal larger problems.

Taking notes on these symptoms can help with troubleshooting. Keep a log of occurrences and conditions. This information may shed light on recurring issues. If you find it difficult to identify the problem, seek assistance. Don't hesitate to consult someone with more experience or expertise. Reflection on past issues may lead to better understanding and resolution.

Overflow valve block issues can be frustrating. Several common causes can lead to these problems. Understanding them is essential for effective troubleshooting.

One common issue is debris clogging the valve. Particles can build up over time. This can restrict flow, causing pressure issues. Regular maintenance is crucial. Inspect the valve frequently. Remove any accumulated debris.

Another cause might be a faulty valve itself. Sometimes, a valve can wear out or malfunction. This may require replacement or repair. Always check for signs of wear. Listen for unusual sounds that indicate trouble.

**Tips:** Always have spare seals on hand. They can help during repairs. Consider using a cleaner designed for valves. It can prevent buildup.

Improper installation could also create issues. Ensure everything is fitted correctly during installation. A small mistake can lead to significant problems later. Avoid rushing the installation process. Stay patient and thorough.

Troubleshooting an overflow valve block issue requires a systematic approach. Begin by examining the valve and surrounding components. Check for visible signs of damage or wear. According to industry reports, approximately 30% of valve failures stem from poor maintenance practices. Look for leaks that can indicate faulty seals or joints.

Next, inspect the pressure settings. Utilizing a pressure gauge, measure the inlet and outlet pressures. Research suggests that 40% of operational failures arise from incorrect pressure calibration. If discrepancies arise, adjust settings accordingly or replace the valve. Don't overlook the hydraulic fluid. Contaminated fluid can lead to blockages and malfunctions. A study by the Fluid Power Journal shows that nearly 25% of hydraulic system issues relate to fluid quality.

Finally, conduct a functional test after the inspection. Monitor the valve's response under normal operating conditions. If it fails to perform correctly, consider deeper diagnostics. Be prepared for potential issues that may not be immediately evident. It’s key to reflect on how maintenance routines can impact overall system efficiency. Regular checks and balances can prevent future failures significantly.

Overflow valve blocks are critical in managing fluid pressure. However, these blocks can malfunction, leading to inefficiencies. Understanding the methodologies for repairing these issues can save time and resources. According to industry reports, over 30% of hydraulic system failures stem from overflow valve malfunctions. Regular inspections help identify potential problems early.

To troubleshoot an overflow valve block, start by examining the pressure settings. Incorrect settings can lead to system errors. Inspect all connections. Loose or damaged fittings may cause leaks. It's essential to check for contamination in the hydraulic fluid. Contaminants can lead to blockages and pressure issues.

Tips: Maintain a clean work environment to prevent contamination. Replace worn seals during repairs. Testing after installation ensures functionality. Documentation of repairs aids future troubleshooting efforts. If uncertainties arise, consulting with industry experts can provide invaluable insights. Focus on prevention to maintain efficient operations. Regular training for maintenance personnel can minimize risk factors associated with overflow valve block failures.

Preventing overflow valve issues requires attention to detail and proactive practices. Regular inspection is crucial. Check seals and fittings for wear. Small leaks can lead to significant problems. Keeping the area around the valve clean helps spot potential issues early. Dirt and debris can obstruct flow, making problems worse.

Training operators is also essential. They should understand how to recognize warning signs. Simple training sessions can save time and money. Documenting regular maintenance helps track the valve’s health. If there's a recurring issue, it’s vital to analyze data and adjust practices accordingly.

Another preventative measure is temperature control. Extreme temperatures can affect valve performance. Ensure the environment remains stable and monitor conditions regularly. Simple changes can eliminate many concerns. Listening to feedback from the team can provide additional insights. Over time, these strategies foster a culture of care.

| Issue | Symptoms | Troubleshooting Steps | Preventative Measures |

|---|---|---|---|

| Valve Sticking | Unusual noise, erratic flow | Inspect and clean valve components | Regular maintenance and lubrication |

| Pressure Fluctuations | Inconsistent pressure readings | Check for leaks, inspect seals | Regularly inspect hydraulic fluid levels |

| Fluid Contamination | Discoloration, particulates in fluid | Analyze fluid sample, replace fluid | Use filters and change fluid regularly |

| Seal Wear | Leaking fluid, decreased efficiency | Inspect seals and replace if necessary | Monitor operating conditions to reduce wear |

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy