- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

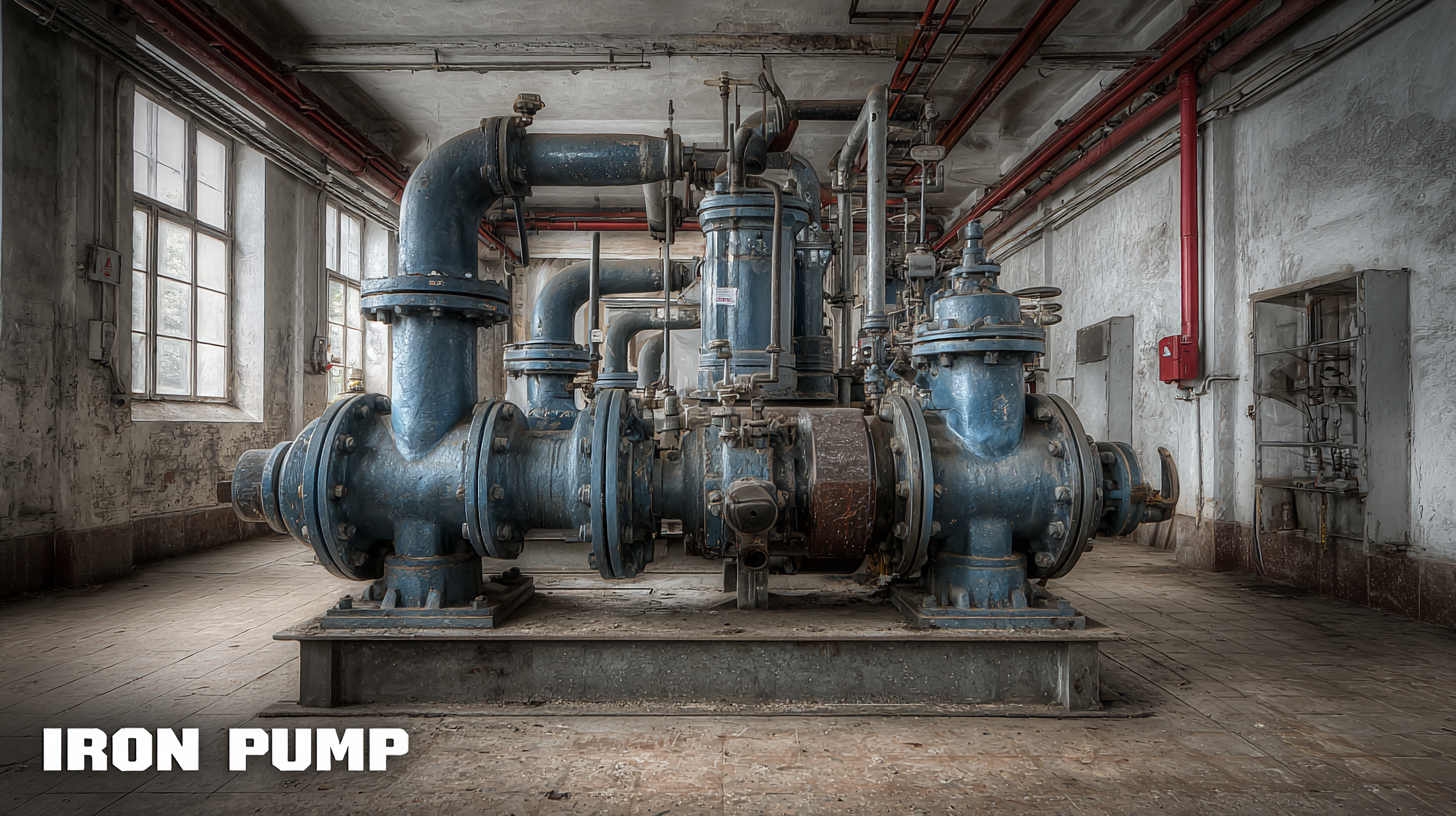

In the industrial sector, selecting the right equipment is paramount to maintaining operational efficiency, and this is especially true when it comes to Iron Pumps. According to the recent report by Global Market Insights, the iron pump market is projected to witness significant growth, driven by the increasing demand for effective fluid management systems across various industries. With factors such as pump design, performance characteristics, and material compatibility playing crucial roles in the selection process, it is essential for factory managers to thoroughly assess their specific needs.

This blog highlights seven essential tips to consider when choosing the best Iron Pump for your factory, ensuring optimal performance while maximizing productivity and minimizing costs.

By understanding the detailed technical parameters and their implications, businesses can make informed decisions that align with their operational goals.

When selecting an iron pump for your factory, it is crucial to first understand your specific requirements. The type of materials you intend to transport, the flow rates needed, and the operating environment all play significant roles in this decision. For example, if your factory handles corrosive or abrasive materials, you will need a pump constructed from durable, resistant materials to ensure longevity and reduce maintenance costs.

Another essential factor to consider is the pump’s capacity and efficiency. Assessing the expected workload helps in choosing a pump that can sustain operational demands without excessive energy consumption. You should also evaluate whether the pump can accommodate fluctuations in production volume. By carefully reviewing these specifications and aligning them with the capabilities of various iron pumps, you can make a well-informed decision that will optimize your factory’s operations for years to come.

| Tip | Description | Considerations |

|---|---|---|

| 1. Assess Pump Capacity | Determine the flow rate and pressure needed for your operations. | Evaluate peak usage times and continuous vs. intermittent operations. |

| 2. Understand Fluid Characteristics | Identify the type of iron and any additives that may affect the pump. | Check for viscosity, temperature, and corrosiveness. |

| 3. Evaluate Maintenance Needs | Consider how often the pump will need servicing and replacement parts availability. | Plan for scheduled and unscheduled maintenance. |

| 4. Look for Energy Efficiency | Choose pumps that consume less energy while maintaining performance. | Calculate long-term operating costs vs. initial purchase price. |

| 5. Check Compatibility with Existing Systems | Ensure the pump fits with your factory's plumbing and power supply. | Assess pipe sizes, electrical requirements, and mounting options. |

| 6. Review Manufacturer Support | Research the level of support provided by the manufacturer. | Inquire about warranties, technical support, and training. |

| 7. Read Customer Reviews | Look for feedback from other users to gauge performance and reliability. | Use credible sources for reviews, focusing on long-term performance. |

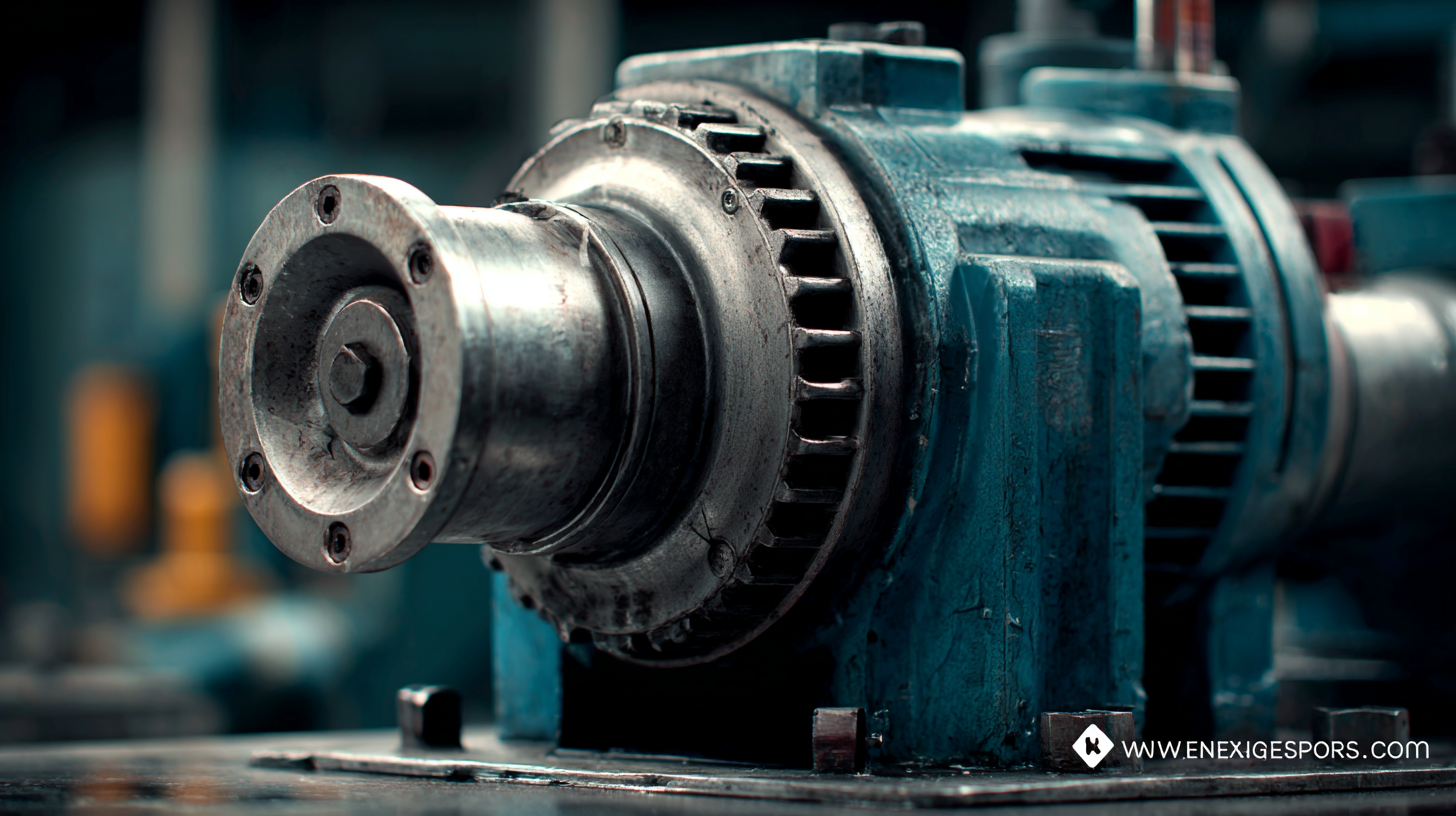

When selecting an iron pump for your factory, it's crucial to evaluate performance metrics that align with your operational requirements. Consider factors such as flow rate, pressure capabilities, and efficiency. A pump's flow rate indicates its capacity to move fluid, which is vital for maintaining productivity in your manufacturing processes. Verify the specifications to ensure the pump can handle the demands of your fluids without overheating or failing.

In addition to flow rate, pay close attention to the pressure ratings. Different applications require specific pressure levels, and understanding these needs helps in choosing a pump that won't underperform. Another metric to consider is the pump's energy efficiency. Opt for models that minimize energy consumption while maximizing output, ultimately reducing operational costs over time.

Lastly, don’t overlook the material composition of the pump. Iron pumps are popular for their durability, but their longevity largely depends on corrosion resistance and the type of fluids being handled. Ensure that the selected pump is suitable for the materials in your factory to avoid premature wear and maintain consistent performance.

When selecting the best iron pump for your factory, researching the manufacturer's reputation and examining customer reviews are crucial steps that should not be overlooked. A reputable manufacturer typically has a track record of producing reliable and high-quality products. Companies with longstanding industry presence often have established relationships with their clients and a history of favorable operations. Look for certifications and industry affiliations that indicate the manufacturer's credibility and commitment to excellence.

Customer reviews offer valuable insights into the performance and reliability of the iron pumps. Reading firsthand accounts from other factory operators can help you gauge how a specific pump performs in real-world conditions. Pay attention to common themes in reviews, such as durability, ease of installation, and maintenance requirements. Additionally, consider both positive and negative feedback to get a balanced perspective. Engaging in online forums or industry-specific discussions can also provide information on customer satisfaction and potential drawbacks of particular models, enabling you to make a more informed decision.

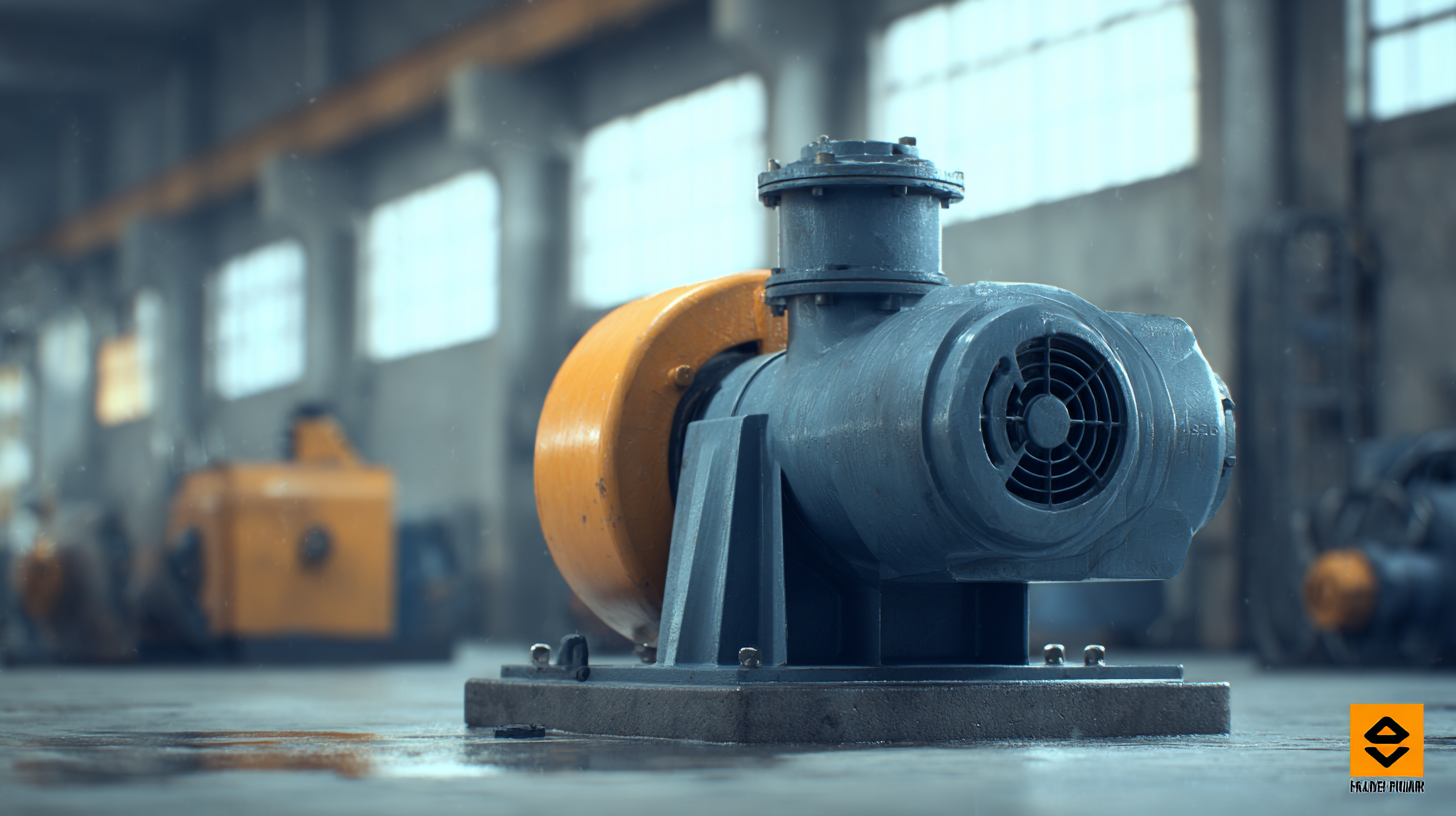

When selecting the best iron pump for your factory, it's crucial to assess the quality assurance practices in iron pump production. Quality assurance ensures that the iron pump performs reliably under various operational conditions. Manufacturers should implement stringent testing protocols that evaluate key performance indicators such as pressure capacity, flow rate, and durability. Additionally, a comprehensive quality management system should be in place, which includes regular audits and compliance with industry standards to mitigate the risks of defects.

Moreover, the relationship between water quality management and iron pump production cannot be overlooked. As seen in recent studies, the management of irrigation water quality is vital for agricultural success. This involves assessing factors like salinity and pH levels, which can be directly influenced by the pumps used in irrigation systems. Ensuring that iron pumps are designed with water quality considerations in mind can enhance not only crop production efficiency but also environmental sustainability. By prioritizing quality assurance and integrating it with a broader understanding of water management, manufacturers can deliver superior iron pumps that meet the diverse needs of their clients.

When selecting the best iron pump for your factory, after-sales support and maintenance services are crucial factors that can significantly impact your operations. Reliable maintenance services not only ensure the longevity of your equipment but also reduce unexpected downtimes that can hamper production. According to industry reports, effective after-sales support can enhance equipment lifespan by up to 30%, providing a substantial return on investment.

Tip: Choose a supplier that offers comprehensive maintenance packages tailored to your specific needs. Look for providers with a proven track record, as highlighted by recent news of service agreements including heavy maintenance for aircraft and comprehensive maintenance solutions for rail systems. Such partnerships often guarantee dedicated support, ensuring your equipment operates optimally at all times.

Tip: Verify the availability of technicians and support staff in your region. Quick access to support is vital, especially in industries like manufacturing, where delays can lead to significant financial loss. Establishing a strong relationship with your equipment provider can lead to smoother service agreements and better responsiveness, as seen in recent contracts within various sectors. Prioritizing after-sales support not only boosts your productivity but also fortifies your overall operational efficiency.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy