- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

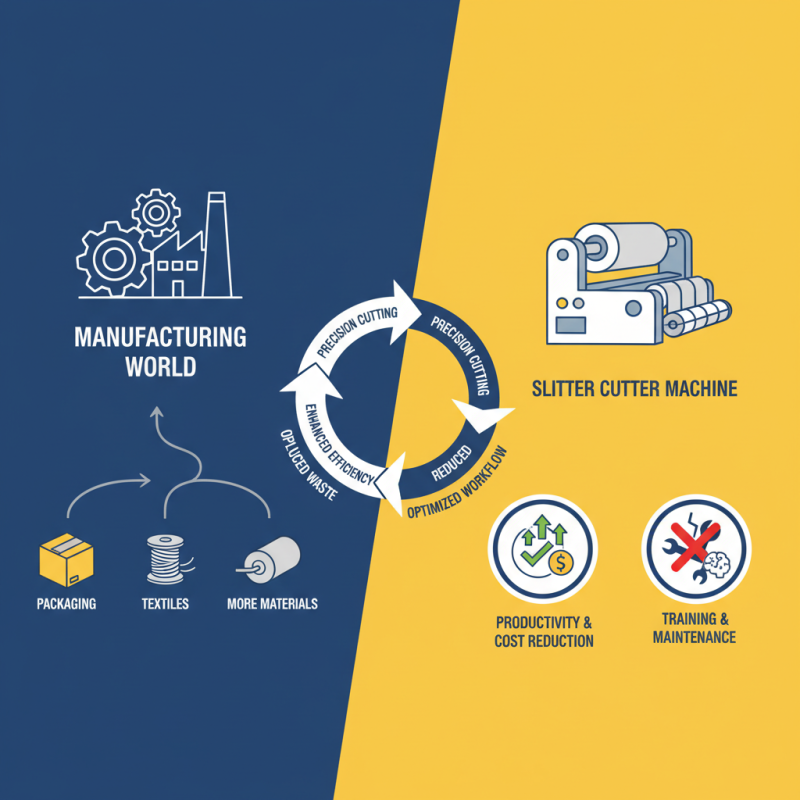

In the manufacturing world, the Slitter Cutter Machine plays a crucial role. Experts like John Smith, a leader in production technologies, state, “The versatility of slitter cutter machines is unmatched.”

These machines are essential in various industries. They cut materials into precise widths for packaging, textiles, and more. Imagine a bustling factory floor with machines humming, where efficiency is key. Without a reliable slitter cutter, workflows can slow dramatically.

However, it’s not all straightforward. Some operators struggle to optimize their usage. Misalignment can cause waste, highlighting the need for training and awareness. The true potential of a Slitter Cutter Machine lies in its proper handling and maintenance. By understanding its uses and benefits, manufacturers can enhance productivity and reduce costs.

Slitter cutter machines are essential in various industries. They are designed to cut large rolls of material into manageable sizes. These machines work by utilizing sharp blades to make precise cuts, significantly enhancing efficiency. The global slitting machine market is projected to reach $5 billion by 2027, according to industry reports. This growth showcases their importance in manufacturing.

The functionality of slitter cutter machines extends to numerous materials. They are commonly used for paper, plastic films, rubber, and metal. Each material requires specific blade configurations for optimal performance. However, incorrect settings may lead to increased waste and reduced efficiency. Industry surveys indicate that nearly 20% of operators encounter challenges in adjusting machine settings properly.

Additionally, maintenance is crucial for sustained performance. Regular inspections help to avoid potential breakdowns. Despite this, some facilities skip routine checks. This could lead to unexpected downtimes. It is vital to prioritize training for operators on machine handling. Without proper knowledge, even the best equipment can underperform. Balancing efficiency with operator skill is a persistent challenge in the industry.

| Use/Benefit | Description | Industry Applications |

|---|---|---|

| Precision Cutting | Produces accurate cuts for various materials. | Packaging, Textiles |

| Material Efficiency | Reduces waste during the cutting process. | Manufacturing, Printing |

| Versatility | Can cut a wide range of materials, including plastic, film, and paper. | Food, Electronics |

| Increased Productivity | High-speed cutting capabilities improve production rates. | Industrial Manufacturing |

| User-Friendly Operation | Designed for ease of use with minimal training necessary. | Small and Medium Enterprises |

| Automated Cutting | Can be integrated with automated systems for streamlined operations. | Automotive, Aerospace |

| Custom Applications | Tailored cutting solutions for specific projects and materials. | Custom Manufacturing |

| Safety Features | Equipped with safety mechanisms to protect operators. | Any Industry |

| Cost-Effective | Reduces labor costs and material wastage. | Retail, Wholesale |

| Quality Control | Ensures high quality of cuts to meet industry standards. | Pharmaceuticals, Food Production |

Slitter cutter machines play a vital role in various industries. They are primarily used to process materials into desired widths. A wide range of materials can be efficiently handled by these machines. Commonly, flexible materials like paper and film are cut with precision. The slitter cutter is essential in the packaging industry. It ensures that dimensions meet exact specifications.

Foils and laminates are other materials often processed. The Slitter cutter cuts them into strips or smaller sections. This is crucial for manufacturers who need specific sizes for their products. Additionally, textiles are a growing area where slitter cutters are used. They help in achieving exact fabric widths for further production.

In some cases, operators may face challenges when processing different materials. Different thicknesses can affect cutting quality. Some materials create more waste than others. This can lead to higher costs and inefficiencies. Overall, while slitter cutter machines have many benefits, there is a need to fine-tune processes for optimal results. Identifying material-specific needs is key to improving efficiency and reducing waste.

Slitter cutter technology plays a vital role in various industries. The packaging sector is a prime example. Here, slitting machines cut large rolls of material into smaller, manageable pieces. This process ensures efficient material utilization. Flexible packaging often requires precise cuts to maintain quality. Any mistake can lead to waste and affect production schedules.

The textile industry also benefits from slitter cutter machines. They offer accurate cutting of fabric, which reduces the risk of fraying. This precision is crucial for maintaining fabric integrity. Without these machines, cutting would be a labor-intensive process. Manual cutting cannot match the speed or accuracy of automated systems.

Another key area is the automotive industry. Slitter cutters are used for producing gaskets and seals. These parts need to fit perfectly in vehicles. A slight error in cutting can lead to issues in assembly. The need for precision is crucial here. Overall, as industries evolve, the demand for reliable slitting technology grows. Companies must continually assess their processes to enhance efficiency. This reflection is essential for staying competitive.

Slitter cutter machines play a crucial role in modern manufacturing. These machines efficiently convert large rolls of material into narrower strips. This process is essential in industries such as packaging, textiles, and automotive. Manufacturers have reported that using slitter cutter machines can reduce material waste by up to 30%. This not only saves costs but also contributes to sustainability goals.

One key benefit of slitter cutter machines is their versatility. They can handle various materials, from paper to plastic. The ability to slit multiple layers simultaneously increases productivity. Data indicates that companies utilizing these machines experience a production increase of approximately 25%.

Tip: Regular maintenance is vital. Ensure that blades are sharp and aligned for optimal performance. This can prevent unnecessary downtime.

Another benefit is precision. Slitter machines can achieve high accuracy in cutting dimensions. This reduces errors in the final product and improves quality. However, depending on machine calibration, variations can still occur. Monitoring is essential to maintain consistency.

Tip: Train operators regularly. Well-informed staff can mitigate common issues and enhance the machine's effectiveness.

Integrating slitter cutter machines into production lines offers significant advantages. However, businesses must continuously evaluate and adapt to maximize these benefits.

When selecting a slitter cutter machine, several key factors come into play. The material type is vital. Different materials may require specific cutting mechanisms for optimal results. Thickness is another factor. A thicker material may need a more robust machine. Always consider the machine's cutting speed. Faster machines can improve efficiency but may also increase wear and tear.

Precision is crucial. Look for machines that offer adjustable settings. This flexibility allows for better control over the cutting process. The design matters too. A compact machine can save space but might limit cutting capabilities. Maintenance requirements should not be overlooked. Some machines demand regular upkeep, while others are more forgiving.

Cost is always a consideration. Cheaper machines may compromise on quality. However, extremely high-end models may offer features that most businesses don’t need. Operators' skill level is another point. A complex machine may require extensive training. This could lead to longer onboarding times. Balancing these factors can make the selection process challenging yet critical for operational success.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy