- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

The optimization of gear hydraulic systems has become increasingly critical in various industries, as efficient hydraulic systems can significantly enhance overall machine performance while reducing operational costs.

According to a report by the International Journal of Fluid Power, optimal design and maintenance of hydraulic systems can lead to efficiency improvements of up to 30%. Moreover, the American Society of Mechanical Engineers (ASME) indicates that properly calibrated gear hydraulic systems contribute to more than 70% of the total power savings in industrial applications. These compelling statistics underscore the necessity for engineers and technicians to focus on optimization strategies.

By exploring methods such as fluid viscosity management, system component selection, and regular maintenance protocols, businesses can maximize the efficiency and performance of their gear hydraulic systems, ensuring long-term reliability and cost-effectiveness in their operations.

The optimization of gear hydraulic systems has become increasingly critical in various industries, as efficient hydraulic systems can significantly enhance overall machine performance while reducing operational costs.

According to a report by the International Journal of Fluid Power, optimal design and maintenance of hydraulic systems can lead to efficiency improvements of up to 30%. Moreover, the American Society of Mechanical Engineers (ASME) indicates that properly calibrated gear hydraulic systems contribute to more than 70% of the total power savings in industrial applications. These compelling statistics underscore the necessity for engineers and technicians to focus on optimization strategies.

By exploring methods such as fluid viscosity management, system component selection, and regular maintenance protocols, businesses can maximize the efficiency and performance of their gear hydraulic systems, ensuring long-term reliability and cost-effectiveness in their operations.

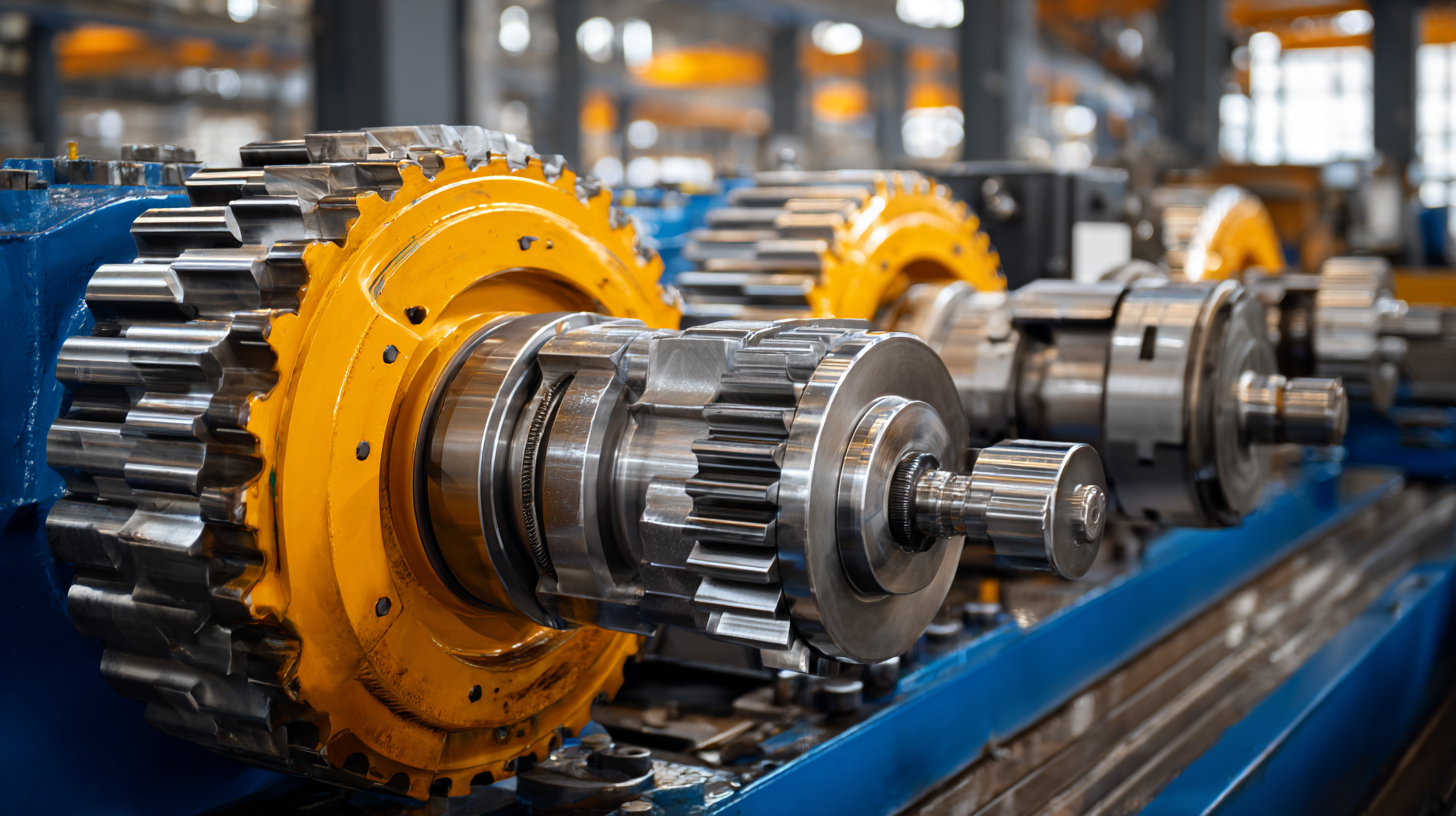

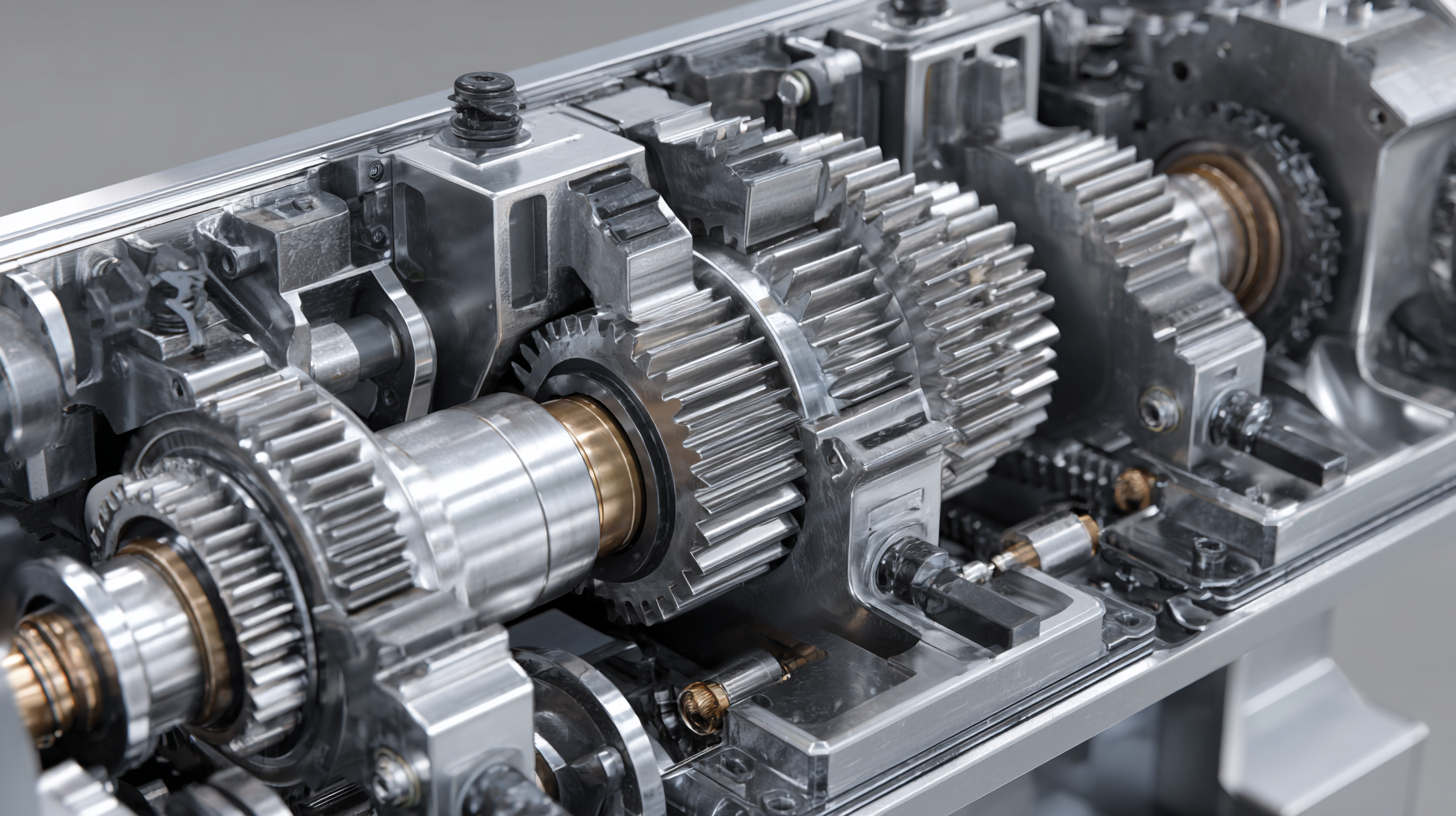

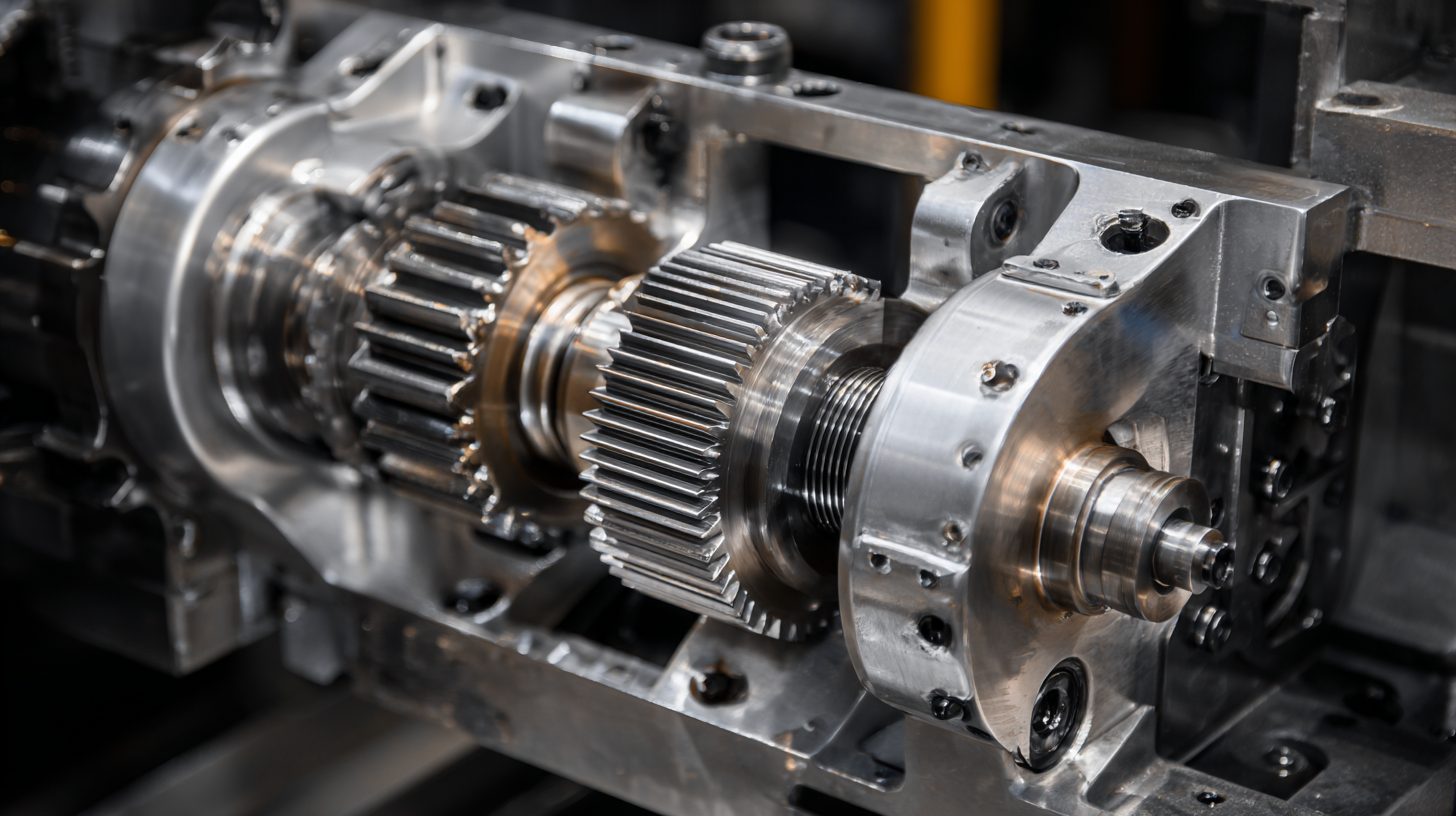

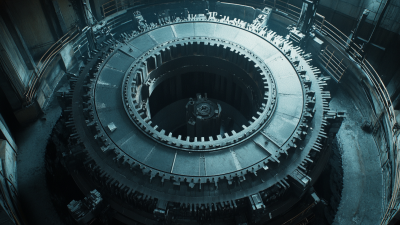

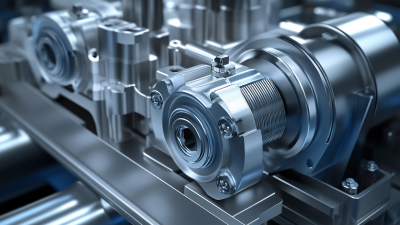

Gear hydraulic systems play a crucial role in various industrial applications, providing efficient power transfer and control. Understanding the key components of these systems is essential to optimize their performance and maximize efficiency. The main components include the hydraulic pump, motors, reservoirs, valves, and the hydraulic fluid. Each part has a distinct role: the pump generates flow, the motor converts hydraulic energy into mechanical energy, and the valves regulate the flow and direction of the hydraulic fluid, while the reservoir stores the fluid.

To enhance the efficiency of gear hydraulic systems, it’s important to focus on regular maintenance. Ensure that the hydraulic fluid is clean and at the appropriate levels to avoid unnecessary wear on components. Additionally, monitoring the temperature of the system can prevent overheating, which can lead to decreased performance.

Another tip is to select the right size of components to avoid bottlenecks in the system. Oversized or undersized pumps and motors can lead to inefficiencies. Finally, using advanced control systems can help in optimizing the operation by adjusting flow rates and pressures based on the demands of the application, ensuring that the system runs smoothly and efficiently.

| Component | Role | Efficiency Impact (%) | Optimal Operating Conditions |

|---|---|---|---|

| Hydraulic Pump | Converts mechanical energy to hydraulic energy | 85-95% | 2000-3000 RPM |

| Hydraulic Cylinder | Converts hydraulic energy to mechanical energy | 90-95% | 5-2000 PSI |

| Gear Motor | Drives machinery by converting hydraulic pressure to rotational motion | 88-93% | 1500-2500 RPM |

| Valves | Control the flow and pressure of hydraulic fluid | 70-80% | Varies with application |

| Reservoir | Stores hydraulic fluid and allows for expansion and heat dissipation | N/A | Optimal fluid level maintained |

One critical issue in optimizing gear hydraulic systems is identifying common sources of efficiency loss. According to a report by the Hydraulic Institute, hydraulic systems can typically experience efficiency losses of 10-30% due to various factors, including thermal inefficiencies and leakage. These inefficiencies not only increase operational costs but can also lead to reduced system performance and longevity. It’s essential for engineers to conduct thorough assessments of the components within the hydraulic system, including pumps, valves, and cylinders, to pinpoint areas that may be contributing to energy waste.

Another prevalent source of efficiency loss in hydraulic systems is improper fluid management. The National Fluid Power Association notes that up to 25% of energy consumption in hydraulic circuits can be attributed to inadequate fluid viscosity and contamination. Maintaining optimal fluid conditions is vital, as degraded fluid can lead to increased friction and heat generation. Implementing regular maintenance schedules, along with fluid quality monitoring, can significantly enhance overall system performance and prevent costly downtimes that stem from inefficient hydraulic operations. Employing advanced filtration systems and selecting appropriate fluid types tailored to specific operating conditions are strategies that can greatly mitigate these losses.

Choosing the right hydraulic fluid is crucial for optimizing gear hydraulic systems. According to a study by the International Fluid Power Society, the correct fluid selection can improve system efficiency by up to 15%, significantly impacting performance and longevity. Synthetic fluids, for instance, often provide superior thermal stability and reduced viscosity change under varying temperatures, making them a preferred choice in high-performance applications.

Tip: When selecting a hydraulic fluid, consider factors such as temperature range and potential for fluid degradation. For extreme temperature environments, look for fluids with high thermal stability and low pour points.

Moreover, the use of biodegradable fluids has gained traction in recent years, as highlighted in a report by the Society of Automotive Engineers. These fluids not only reduce environmental impact but can also enhance system performance when formulated correctly. They often provide lower volatility rates and better lubricating properties, which contribute to extending the life of hydraulic components.

Tip: Regularly monitor fluid condition and change intervals to ensure optimal performance. Implementing a fluid monitoring system can help identify degradation early, preventing costly system failures.

Regular maintenance and monitoring are essential for ensuring the optimal performance of gear hydraulic systems. One effective technique is establishing a routine inspection schedule that includes checking fluid levels, filters, and connections. This ensures that any leaks or blockages are identified early, helping to maintain fluid cleanliness and system integrity. Additionally, monitoring fluid condition through regular sampling can detect contamination or degradation, allowing for timely fluid replacement and optimal lubrication.

Another crucial aspect of maintenance is the monitoring of system pressures and temperatures. Using pressure gauges and thermometers, operators can track operational parameters and identify any anomalies that could indicate impending failures. Implementing data logging systems can enhance this process by providing a historical record of system performance, helping engineers understand trends and make data-driven decisions for corrective actions. By prioritizing these techniques for regular upkeep, hydraulic systems can achieve maximum efficiency and longevity, ultimately enhancing overall productivity.

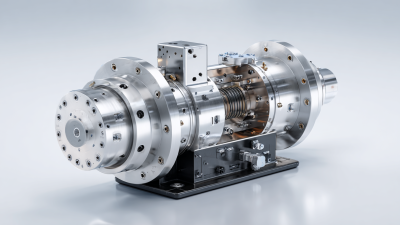

Implementing advanced control technologies is crucial for optimizing gear hydraulic systems while maximizing efficiency and performance. Modern control systems, such as proportional and servo valves, allow for precise modulation of hydraulic flow and pressure, leading to improved responsiveness and reduced energy consumption. By integrating these technologies, operators can achieve notable improvements in system dynamics, enabling faster cycle times and enhanced precision in performance outputs.

Tips for implementation include regularly updating software and firmware of control systems to ensure optimal functionality. Additionally, using real-time monitoring tools can provide insights into system performance, allowing for timely adjustments. Opt for predictive maintenance technologies to identify potential issues before they escalate, ensuring reliability and minimizing downtime.

Lastly, consider training personnel on advanced control strategies and technologies. A well-informed team can better manage the complexities of these systems, allowing for effective troubleshooting and optimization. Emphasizing education and skill development will not only enhance system performance but also promote a culture of continuous improvement within the organization.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy