- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In recent years, the demand for highly efficient systems in various industries has led to significant advancements in hydraulic technology, particularly with hydraulic gears. According to a report by Market Research Future, the hydraulic gear market is projected to grow at a CAGR of 5.2% between 2021 and 2027, driven by increased automation in construction and agriculture sectors. As we look toward 2025, it's crucial to understand the technological development trends and explore alternatives that can further enhance efficiency.

The evolving landscape of hydraulic gear not only involves the integration of smart technologies but also emphasizes sustainable practices, which can reduce energy consumption and operational costs. By optimizing hydraulic systems with the best hydraulic gear, businesses can achieve higher productivity, underscoring the importance of continuously adapting to these advancements in an ever-competitive market.

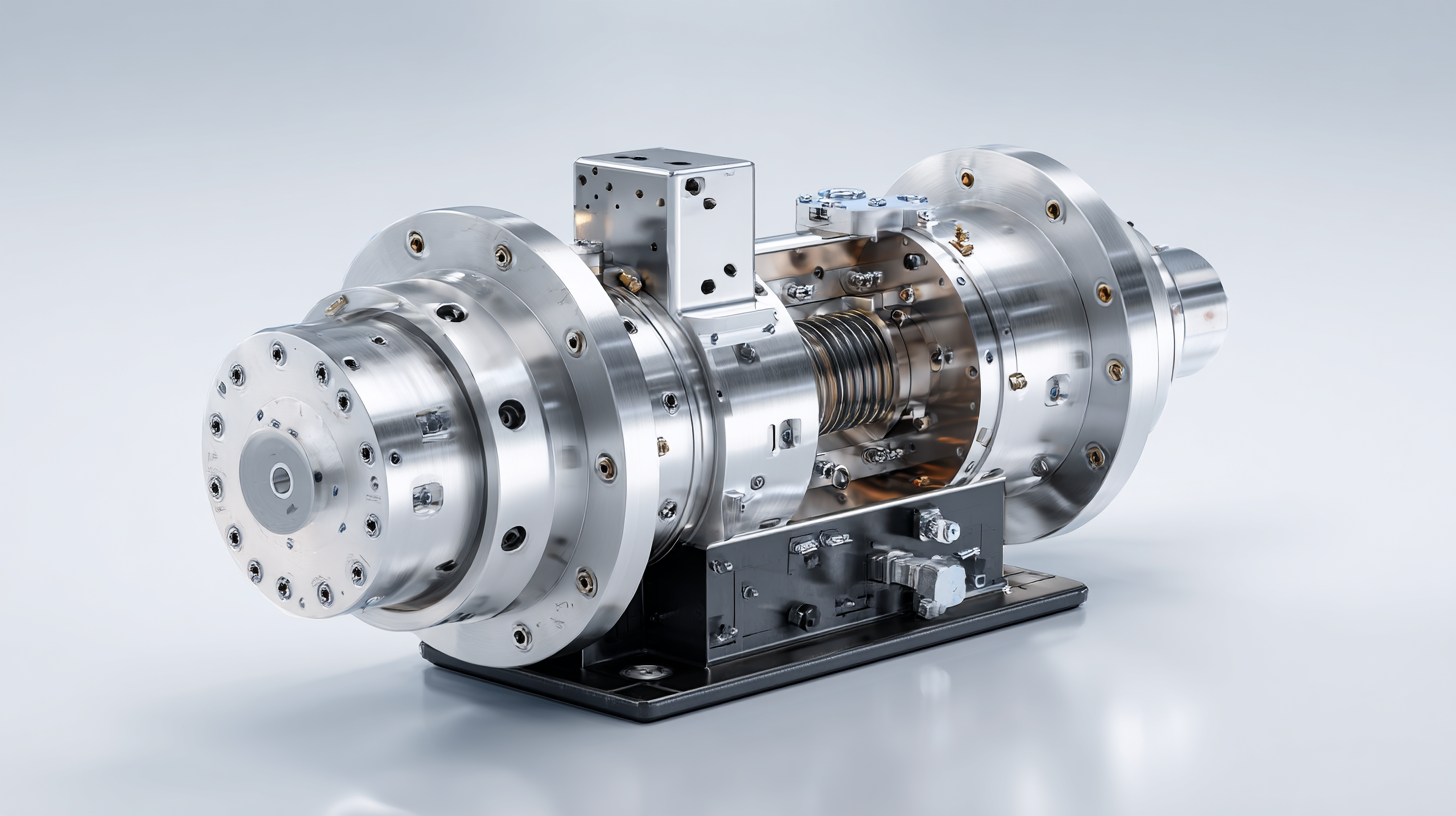

Hydraulic gears play a critical role in various industries, powering machinery and equipment that are essential for efficient operations. Their ability to transmit power through fluid pressure allows for smoother functionality and enhanced performance in demanding environments such as construction, manufacturing, and automotive sectors. By converting hydraulic energy into mechanical motion, these gears facilitate precise control over heavy loads, making them indispensable in operations where traditional gear systems may falter.

The importance of hydraulic gears extends to their versatility. They can be tailored to meet the specific needs of different applications, from compact hydraulic systems in small machinery to larger, more complex setups in industrial plants. This adaptability not only improves operational efficiency but also drives innovation, allowing industries to optimize workflows and reduce downtime. As companies increasingly seek to maximize productivity, investing in high-quality hydraulic gears becomes essential for maintaining a competitive edge in today's fast-paced market.

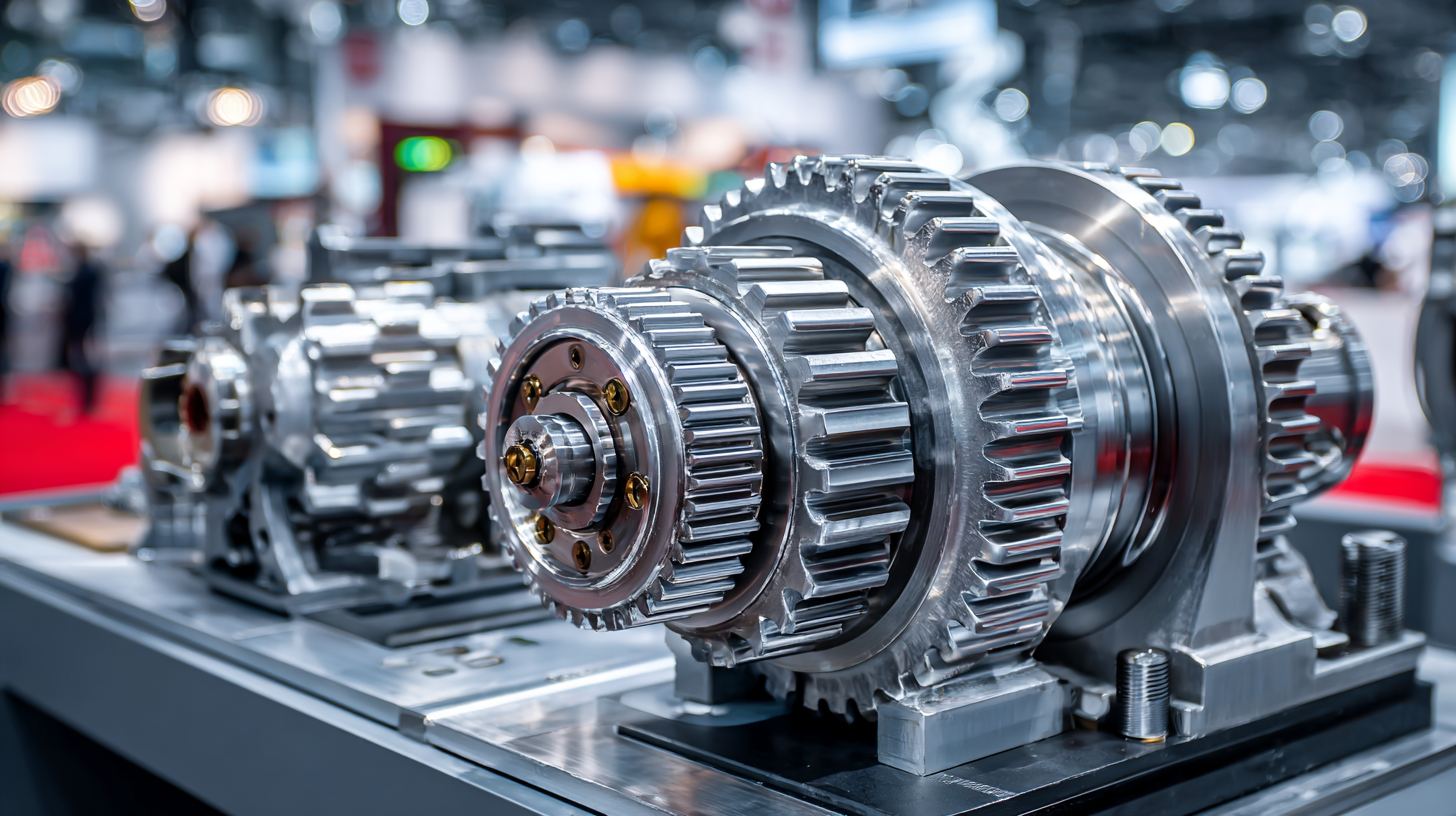

When selecting high-performance hydraulic gears, understanding key features is essential for maximizing efficiency. Look for gears made from high-quality materials that reduce friction and wear. The global industrial lubricants market is projected to reach $740.5 billion by 2024, showcasing the continuous demand for superior lubrication in hydraulic systems. Effective lubrication ensures optimal performance and longevity of hydraulic gears, crucial for industries such as automotive and aerospace.

Another significant feature to consider is the gear's load capacity. High-performance hydraulic gears should withstand varying loads without compromising efficiency. As the demand for advanced lubricants grows, the synthetic lubricant segment is expected to play a pivotal role, with notable applications in hydraulic systems. This aligns with the projected growth of high-performance lubricant markets, anticipated to reach $969.3 billion by 2032 at a CAGR of 3.3%.

Tips: Regularly monitor lubrication levels and replace fluids as needed to maintain gear performance. Additionally, consider compatibility with the specific type of hydraulic oils, as this can significantly affect gear efficiency and lifespan. Investing in robust high-performance hydraulic gears tailored to industry standards not only boosts productivity but also ensures a sustainable operational horizon.

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Gear Ratio | The ratio between the input speed and output speed of the gear system. | Optimizing gear ratios can improve torque and reduce energy loss. |

| Material Quality | High-strength, durable materials resistant to wear and tear. | Enhances the lifespan of gears and decreases maintenance costs. |

| Sealing Technology | Advanced sealing mechanisms to prevent leakage and contamination. | Improves performance consistency and reduces system downtime. |

| Maintenance Accessibility | Design elements that allow for easy inspection and maintenance. | Facilitates timely maintenance, ensuring optimal operation. |

| Load Capacity | Maximum load the hydraulic gear can handle effectively. | Higher load capacity ensures the gear can perform under demanding conditions without failure. |

| Temperature Resistance | Ability to operate effectively at varying temperature conditions. | Prevents overheating and ensures efficiency across a range of operating environments. |

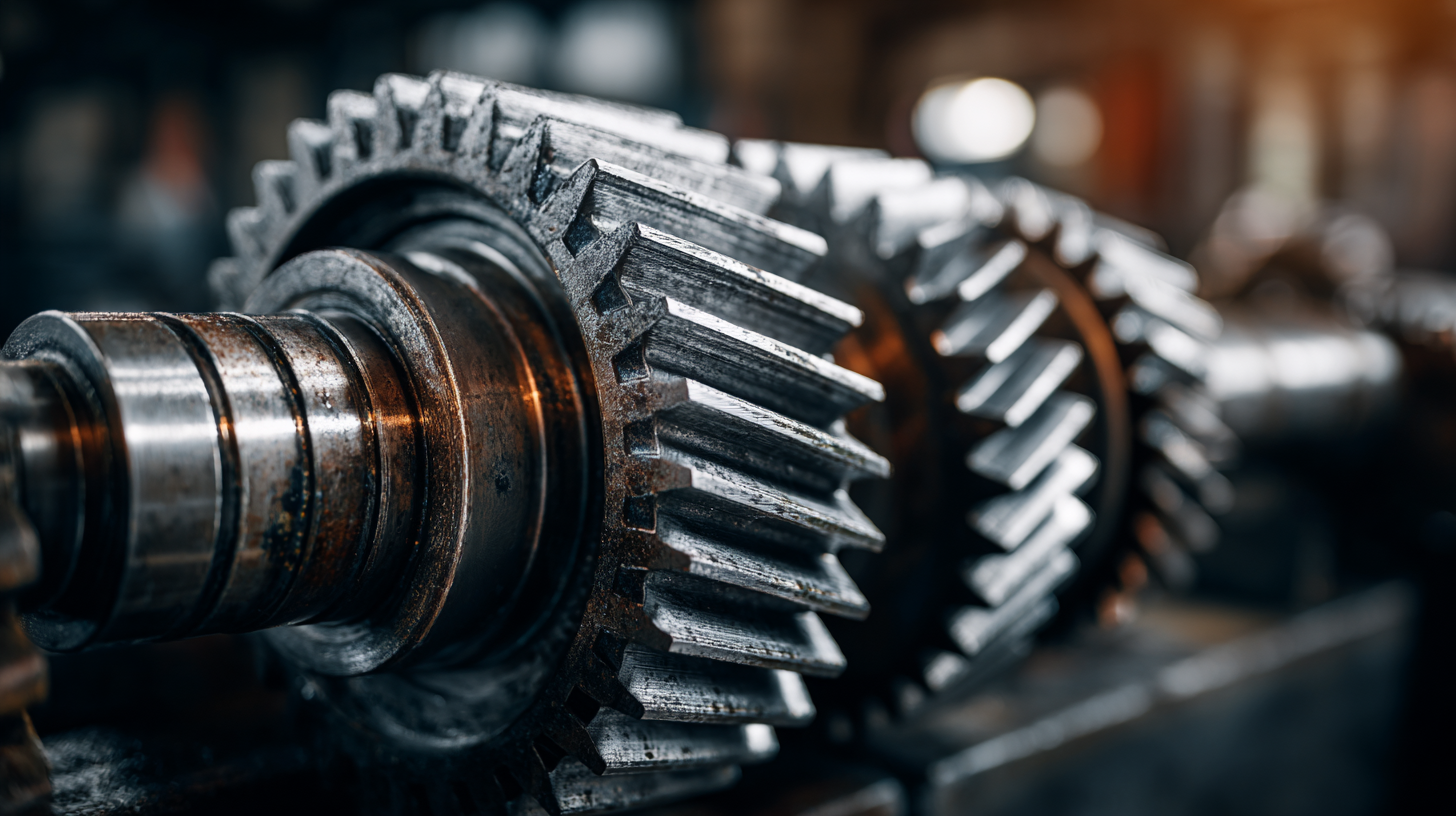

Maintaining hydraulic gear is essential for maximizing efficiency in any operation that relies on these powerful systems. One of the best practices for ensuring optimal performance is adhering to a regular maintenance schedule. Regular inspections allow operators to identify and address potential issues before they escalate into costly repairs or equipment failures. Check for signs of wear and tear, fluid leaks, and the condition of hoses and fittings. Keeping hydraulic fluid clean and at the proper level is crucial; dirty or insufficient fluid can lead to pump damage and reduced efficiency.

Another vital aspect of hydraulic gear maintenance is proper filtration. High-quality filters should be used to prevent contaminants from entering the hydraulic system, as impurities can cause significant damage over time. Additionally, staff training is critical. Ensuring that team members are well-versed in the operation and maintenance of hydraulic gear can greatly reduce the risk of human error, prolong equipment lifespan, and enhance overall productivity. By implementing these best practices, organizations can maximize the efficiency of their hydraulic systems, leading to smoother operations and increased reliability.

This chart illustrates the average efficiency gains observed with various maintenance practices for hydraulic gear over a 12-month period. Regular maintenance, such as fluid checks and filter replacements, significantly increases efficiency compared to infrequent or no maintenance.

Choosing the right hydraulic gear is essential for maximizing efficiency in various industrial applications. Begin by assessing the specific needs of your operation. Consider factors such as the type of hydraulic fluids you will use, the working pressure, and the load capacity required. Different hydraulic gears are designed to perform optimally under varying conditions, so understanding your operational context will guide you to the best options.

Next, evaluate the quality and compatibility of the hydraulic gear with existing equipment. Look for reputable manufacturers that provide reliable performance and have a proven track record in the industry. Furthermore, pay attention to the gear size and configuration; proper matching with your hydraulic system ensures smoother operation and reduces the risk of malfunctions. By taking the time to thoroughly research and select the appropriate hydraulic gear, you can greatly enhance efficiency and ultimately improve the productivity of your operations.

The evolution of hydraulic gear technologies has paved the way for enhanced performance and efficiency in various applications. Innovations such as variable displacement pumps and advanced hydraulic fluids have significantly improved the responsiveness and adaptability of hydraulic systems. These technologies facilitate real-time adjustments, allowing machinery to operate under optimal conditions, thus reducing wear and tear while maximizing output.

Furthermore, the integration of smart sensors and IoT capabilities in hydraulic systems has revolutionized how data is collected and utilized. These innovations enable predictive maintenance, allowing operators to detect potential issues before they escalate, thereby minimizing downtime. With real-time monitoring, companies can also optimize energy consumption, leading to sustainable operations without compromising performance. By adopting these cutting-edge technologies, industries can harness the full potential of their hydraulic gear, achieving greater efficiency and reliability in their operations.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy