- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

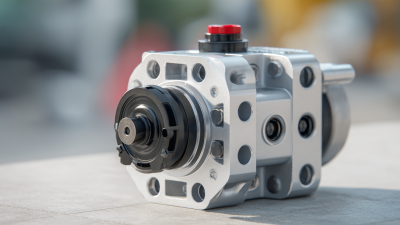

In the competitive landscape of industrial manufacturing, pump manufacturers are increasingly facing challenges that demand innovative solutions for efficiency. According to a market report by TechNavio, the global pump market is poised to grow by 3.5% annually, reaching an estimated value of $90 billion by 2026. However, with rising material costs and stricter regulatory standards, manufacturers must explore advanced techniques in design and production to remain profitable. The need for lean manufacturing processes and automation has never been more pressing, as inefficiencies can lead to significant financial losses. Therefore, this blog will delve into contemporary issues impacting pump manufacturing, emphasizing the necessity for new approaches that enhance operational efficiency while addressing quality and performance concerns.

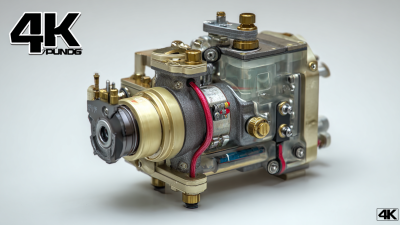

The industrial pump manufacturing landscape is experiencing a paradigm shift driven by emerging technologies that enhance efficiency and productivity. With the integration of advanced techniques such as bio-microsystem technology and Lab-on-PCB innovations, the development of micro-total analysis systems (µTAS) is increasingly relevant. These innovations facilitate streamlined processes and compact designs, enabling manufacturers to push the boundaries of traditional pump functions.

In addition to these advancements, generative AI is becoming a pivotal force in the manufacturing sector. By harnessing powerful machine learning algorithms, companies can optimize production cycles, predict maintenance needs, and reduce waste. This technology can help in designing pumps that are not only functional but also environmentally friendly, addressing the industry's need for sustainable practices.

**Tips for Manufacturers:**

1. Invest in training your workforce on advanced technologies such as AI and micro-manufacturing techniques to stay ahead in the competitive market.

2. Explore partnerships with tech firms specializing in innovative solutions to leverage cutting-edge knowledge and resources.

3. Regularly assess and adapt your manufacturing processes to incorporate emerging technologies that can lead to improved operational efficiency and reduced costs.

| Technology | Description | Advantages | Implementation Stage |

|---|---|---|---|

| 3D Printing | Additive manufacturing techniques for creating pump components. | Reduced waste, faster prototyping, complex geometries. | Pilot projects nationwide |

| IoT Integration | Smart sensors and monitoring systems for real-time data. | Improved efficiency, predictive maintenance, energy savings. | Fully implemented in select plants |

| Robotics Automation | Use of robots for assembly and quality control. | Increased precision, reduced labor costs, faster production rates. | Gradual integration ongoing |

| Simulation and Modeling | Digital twins and modeling software for design testing. | Enhanced design accuracy, reduced physical prototyping needs. | Research and development phase |

| Material Advancements | Development of new composite materials for pump construction. | Higher durability, corrosion resistance, and lighter weight. | Initial trials in production |

In recent years, the pump manufacturing industry has increasingly recognized the importance of sustainable practices to reduce environmental impact. According to a report by the Global Pumps Market, eco-friendly manufacturing processes can lead to significant cost savings, with companies reporting reductions in energy consumption by up to 30% by adopting green technologies. These practices not only enhance a company's environmental footprint but also align with the growing regulatory requirements aimed at promoting sustainability.

One key area of focus in eco-friendly pump production is the use of renewable materials and advanced recycling methods. Studies indicate that up to 70% of the materials used in pump manufacturing can be recycled or sourced sustainably. For example, companies are now utilizing biodegradable plastics and recycled metals, which can help reduce waste and lower the carbon footprint associated with production.

Additionally, the implementation of energy-efficient machinery and production techniques can further bolster sustainability goals, with reports showing that firms adopting these technologies have seen a 25% decrease in greenhouse gas emissions. As the industry moves towards more sustainable practices, the commitment to eco-friendly production will not only benefit the environment but also enhance market competitiveness.

In today's fast-paced manufacturing environment, leveraging automation and robotics in pump assembly lines has become a game-changer. These innovative technologies not only enhance production efficiency but also improve precision, significantly reducing human error. Integrated robotics can streamline the assembly process by taking on repetitive tasks, thereby allowing skilled workers to focus on more complex and value-added operations.

Tip: When considering automation, it's essential to conduct a thorough analysis of your assembly line. Identify bottlenecks and areas where robotics can deliver the most impact. Investing in customized robotic solutions can lead to substantial long-term savings and increased productivity.

Furthermore, the integration of smart robotics can facilitate real-time data collection and monitoring, leading to improved quality control. Automation systems can automatically adjust their operations based on real-time metrics, helping manufacturers to maintain high standards consistently.

Tip: Collaborate with technology providers to ensure you select the right automation tools that align with your specific manufacturing needs. Regular training for your workforce on these technologies will also foster a smoother transition and maximize the benefits of automation.

In the world of pump manufacturing, ensuring the highest quality of products is paramount. Advanced testing techniques have emerged as a crucial component in improving quality control processes. Utilizing methods such as non-destructive testing (NDT) and automated performance assessments, manufacturers can detect flaws or inconsistencies that may compromise the functionality of pumps before they reach the market. This proactive approach not only enhances the durability and reliability of the products but also streamlines the production process by reducing waste and the need for rework.

Moreover, integrating real-time monitoring systems fitted with advanced sensors allows manufacturers to gather continuous data throughout the production cycle. This data-driven approach offers insights into performance metrics and helps in identifying potential issues early in the manufacturing process. By adopting such innovative testing methods, manufacturers can ensure that every pump meets stringent quality standards, ultimately leading to increased customer satisfaction and trust in the brand. As the industry evolves, it is imperative for pump manufacturers to leverage these advanced testing techniques to stay competitive and reinforce their commitment to quality.

The pump manufacturing industry is undergoing significant transformation, driven by the demand for cost-effective strategies that enhance both pump design and production efficiency. Efficient manufacturing techniques are essential as they contribute directly to the reductions in production costs while maintaining high-quality outputs. These innovative solutions range from advanced materials that improve pump durability to automated processes that streamline production workflows.

Market trends indicate a growing adoption of smart technologies in pump systems, including IoT integration for real-time monitoring and optimization. As various vehicle systems increasingly rely on pumps to regulate fluid flow, pressure, and temperature, manufacturers are prioritizing designs that not only meet current performance standards but also focus on sustainability and energy efficiency. Investing in these cost-effective manufacturing strategies not only satisfies regulatory demands but also positions companies to compete more effectively in an evolving marketplace.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy