- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

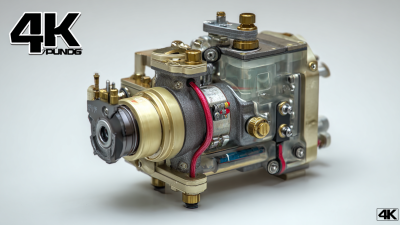

In the realm of modern machinery, the significance of innovative components cannot be overstated, particularly when we delve into the capabilities of Cast Iron Hydraulic Gear Pumps. These pumps, renowned for their durability and efficiency, play a pivotal role in various industrial applications, delivering reliable hydraulic power essential for operation.

The advancements in design and technology surrounding Cast Iron Hydraulic Gear Pumps have transformed their performance characteristics, leading to increased fluid handling capacities and improved energy efficiency. As industries continue to evolve towards more complex and demanding applications, understanding the innovations that underpin these hydraulic systems gains paramount importance.

This inquiry into the 'why' behind the advancements in Cast Iron Hydraulic Gear Pumps not only highlights their vital contributions to modern machinery but also sets a foundation for exploring future trends in hydraulic technology.

The evolution of cast iron materials in hydraulic gear pumps marks a significant advancement in the efficiency and durability of modern machinery. Historically, cast iron has been favored for its robust properties and casting capabilities, allowing for intricate designs and improved performance under high pressure. Over the years, the development of alloys and enhanced manufacturing techniques has further optimized cast iron for hydraulic applications, resulting in pumps that can withstand extreme conditions while maintaining reliable operation.

Incorporating innovations in material science, engineers have refined the composition of cast iron to enhance its resistance to wear and corrosion, making it increasingly suitable for diverse industrial environments. As the demand for more efficient and durable machinery grows, the evolution of these materials continues to play a crucial role in the design and functionality of hydraulic gear pumps. Through advancements in technology, cast iron has solidified its place as a cornerstone in the hydraulics industry, contributing to the increased productivity and reliability of modern machinery.

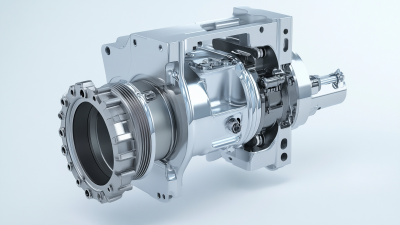

The recent advancements in gear design for cast iron hydraulic gear pumps have significantly improved their efficiency and performance in modern machinery. One of the key innovations is the implementation of optimized gear profiles which reduce hydraulic losses. According to a study by the Hydraulic Institute, these new gear designs can increase volumetric efficiency by up to 15%, which directly correlates to reduced energy consumption and enhanced performance in hydraulic systems.

Moreover, the introduction of advanced materials and manufacturing techniques has further contributed to the reliability and durability of these pumps. The use of precision machining allows for tighter tolerances, leading to lower friction and wear over time. A report from MarketsandMarkets indicates that hydraulic pump efficiency improvements are projected to save industries billions annually, making these innovations not only beneficial for performance but also economically advantageous.

Tips: When selecting a hydraulic gear pump, consider the efficiency ratings provided by manufacturers. Higher efficiency can lead to significant cost savings on energy in the long run. Additionally, keep an eye on maintenance schedules, as regular checks can help sustain the innovation benefits over time.

This chart illustrates the innovations in gear design and their impact on the efficiency of cast iron hydraulic gear pumps over recent years. The data reflects the percentage increase in efficiency due to specific design enhancements such as improved tooth geometry, optimized materials, and advanced manufacturing techniques.

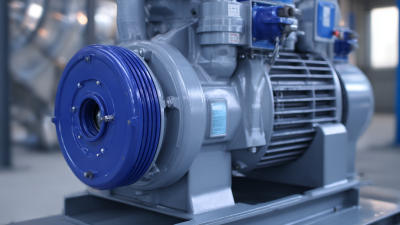

The performance of hydraulic gear pumps, particularly cast iron variants, is crucial in the context of modern machinery operations. According to a report by the Hydraulic Institute, the efficiency and reliability of hydraulic systems can directly influence operational productivity by up to 25%. Cast iron hydraulic gear pumps are renowned for their durability and performance, offering consistent output and minimal downtime. Their robust design facilitates improved pressure capabilities, accommodating various applications from construction equipment to manufacturing processes.

Moreover, advancements in pump design have allowed for significant improvements in noise and vibration reduction, vital metrics in the operation of industrial machinery. The 2022 report from the International Fluid Power Society highlights that higher efficiency pumps can lead to energy savings of up to 15%, translating to a notable reduction in operational costs. Such innovations not only enhance the performance of equipment but also contribute to more sustainable practices in the industry as businesses increasingly seek to optimize energy consumption while meeting stringent environmental regulations. The synergy between pump performance and machinery efficiency ultimately shapes a more productive and environmentally conscious manufacturing landscape.

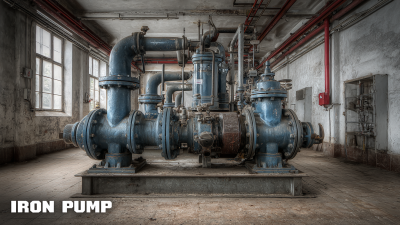

The advancements in cast iron hydraulic gear pumps have significantly addressed the growing demand for sustainability and durability in modern machinery. Cast iron, as a material, offers exceptional durability, enabling pumps to withstand harsh operating conditions without compromising performance. This durability extends the lifecycle of hydraulic systems, reducing the need for frequent replacements and minimizing waste, which is a critical factor in sustainable engineering practices.

Moreover, innovations in the design and manufacturing of cast iron hydraulic gear pumps have led to improved efficiency and reduced energy consumption. Enhanced sealing technologies and precision engineering ensure that these pumps operate with minimal leakage and energy loss. These developments not only contribute to better overall performance but also align with the global push towards eco-friendly practices. By utilizing cast iron's inherent properties along with modern manufacturing techniques, industries can achieve a balance between effective machinery functionality and environmental responsibility.

The future of hydraulic gear pump development is poised for transformative changes, driven by technological advancements and increasing demands for efficiency. According to a report by ResearchAndMarkets, the global hydraulic pump market is expected to grow at a CAGR of 4.5% between 2021 and 2026, reaching approximately $12 billion. This growth is largely fueled by the rising demand for automation in industrial machinery and the need for energy-efficient systems. Innovations such as electronically controlled hydraulic pumps and advanced materials are at the forefront, enhancing operational efficiency and reducing environmental impact.

Moreover, the integration of smart technologies into hydraulic systems is becoming increasingly prevalent. IoT-enabled hydraulic gear pumps allow for real-time monitoring and predictive maintenance, which can reduce downtime and maintenance costs by up to 30%, according to a study by Allied Market Research. As manufacturers continue to prioritize sustainability and operational efficiency, the future will likely see a shift towards pumps that not only perform better but also comply with stricter environmental regulations. This evolution will play a crucial role in applications across various industries, including construction, agriculture, and manufacturing, significantly enhancing performance and reliability.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy