- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

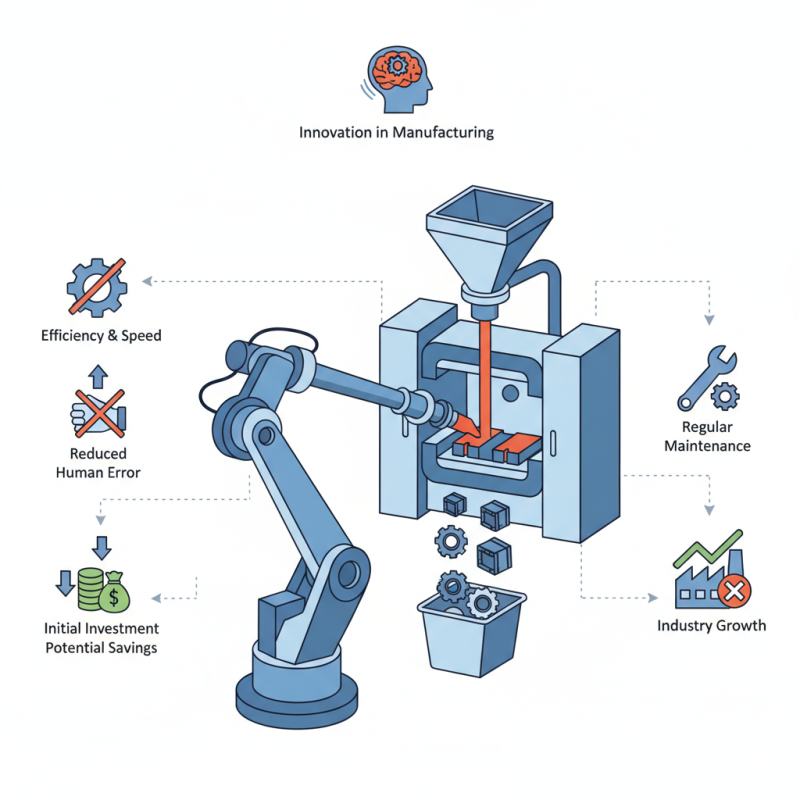

An Injection Machine Robot plays a crucial role in modern manufacturing. This machine automates the injection molding process. It works by melting plastic and injecting it into molds. Once cooled, the molds release shaped products.

These robots improve efficiency substantially. They reduce human error and increase production speed. However, the initial investment can be high. Manufacturers must weigh the costs against potential savings. Not every facility may benefit equally from an Injection Machine Robot. Technical challenges can arise during setup, requiring skilled operators.

Moreover, regular maintenance is essential. A malfunction can halt production lines, leading to delays. Despite these challenges, the advantages often outweigh the drawbacks. The Injection Machine Robot is a fascinating embodiment of innovation in manufacturing. Its effectiveness continues to drive industry growth.

An injection machine robot is a specialized automation system. It is used primarily in the manufacturing sector. This technology is crucial for producing plastic parts and other materials. The robot automates the injection molding process. It ensures precision and speed in production.

These robots operate through a series of motions. They inject molten material into molds, creating specific shapes. The machines often have a mechanical arm for movement. Sensors help them monitor the process. However, there can be challenges. For instance, achieving the perfect temperature is complex. Mistakes in settings can lead to defects.

The efficiency of an injection machine robot is undeniable. Yet, not every machine is perfect. Regular maintenance is necessary to avoid breakdowns. Operators must be trained to manage these systems. This is vital for maximizing output. Each production run offers lessons for improvement. Adaptability is key in this ever-evolving technology landscape.

Injection machine robots are essential in the plastics manufacturing industry. They automate the process of injecting molten material into molds. This creates various plastic products with high precision. Key components of these robots play a crucial role in their functionality.

The main parts include the injection unit, clamping unit, and the control system. The injection unit melts raw plastic and injects it into the mold. Meanwhile, the clamping unit holds the mold tightly during the injection process. If the mold is not clamped properly, it can lead to defects in the final product. The control system manages the entire operation, ensuring that each step is executed smoothly.

Moreover, there are other critical components like the hydraulic system and the ejector mechanism. The hydraulic system provides the necessary force for clamping and injection. If this fails, production can come to a halt. The ejector mechanism releases the finished product from the mold. If it malfunctions, it can damage both the robot and the mold. Understanding these components helps in troubleshooting and optimizing performance. Regular maintenance is crucial for avoiding costly downtimes. The life cycle of an injection machine robot depends significantly on how well these components are cared for.

Injection machine robots play a crucial role in modern manufacturing processes. They automate the injection molding technique, which involves injecting molten material into molds to create various products. The operation of these robots hinges on precision and speed. Typically, they rely on hydraulic or electric systems to control the injection process. This ensures consistent quality and reduces cycle times.

The working mechanism begins with the robot positioning itself accurately above the mold. It uses servo motors for precise movements. Once in place, it injects the material under high pressure. According to industry reports, the global injection molding machine market is projected to grow significantly. It's expected to reach $12 billion by 2025, showcasing the growing demand for automation in manufacturing.

Tips: Regular maintenance of injection machines is crucial. Neglecting it can lead to costly downtimes. Additionally, operators should receive proper training to minimize human errors. Breakdowns often arise from operational oversights. Monitoring system performance is essential for long-term efficiency. Errors in settings might lead to wasted materials and time.

With advancements in technology, robotics are becoming smarter. Yet, there is still room for improvement in terms of integration and flexibility. Automation should complement human effort, not replace it entirely. The need for skilled operators remains vital in navigating complex manufacturing demands.

Injection machine robots play a vital role in modern manufacturing. They automate the injection molding process, significantly enhancing efficiency and precision. Reports suggest that the global market for injection molding robots is expected to grow at a compound annual growth rate (CAGR) of 11.2%, reaching $6 billion by 2025. This growth reflects the increasing demand for high-quality plastic products across various industries.

In applications like automotive and consumer goods, these robots excel at complex tasks. They ensure consistent quality and reduce waste. A study showed that automating these processes can decrease production time by up to 30%. This remarkable efficiency allows manufacturers to meet rising consumer demands quickly. However, reliance on automated systems can lead to challenges. Technical issues or faults in robotic systems could halt production lines, resulting in costly downtime.

Moreover, while these robots enhance safety by reducing human intervention, they cannot replace the creative problem-solving skills of workers. A balance between automation and human oversight is necessary. Companies need to rethink their strategies to incorporate both effectively. Addressing these imperfections will be key for future success in manufacturing processes.

The injection machinery industry is rapidly evolving. Recent reports indicate that the global injection molding machine market is projected to grow at a CAGR of 5% from 2021 to 2026. This growth is driven by increasing demand in sectors like automotive, consumer goods, and healthcare. The push for sustainable manufacturing practices also plays a crucial role. Companies are investing in energy-efficient machines and recyclable materials.

Additionally, automation and smart technologies are transforming injection machinery. With the integration of IoT, machines can now monitor performance in real-time. This leads to reduced downtime and improved efficiency. According to a 2022 study, smart injection molding machines can boost productivity by up to 25%. However, not all companies are adapting at the same pace. Some still rely on traditional practices, risking obsolescence in a competitive market.

Tip: Regularly assess your machinery's efficiency. Investigate whether upgrading to smarter systems could enhance your operations.

Despite these advancements, challenges remain. The initial investment for modern machines can be high. Small businesses often struggle to make the switch, missing out on potential benefits. Additionally, skilled labor shortages can hinder the adoption of new technologies. A balanced approach is key. Embrace innovation while ensuring that workforce training keeps pace with technological changes.

Tip: Create a training program for employees. This ensures they are equipped to handle new technologies effectively.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy