- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

Pump repairs are essential for maintaining the efficiency of your system. Addressing issues early can prevent significant malfunctions. Understanding common problems will help you take proactive measures.

Many users overlook minor leaks or strange noises. Ignoring them may lead to severe damage. You should regularly inspect your pumps. This practice can save you time and money in the long run.

Identifying pump repairs begins with observing performance. If a pump is noisy or vibrates excessively, something may be wrong. Regular maintenance can prevent these issues from escalating. A small crack could lead to a major failure if not fixed promptly. Always be aware of your equipment's behavior to ensure longevity.

Pump problems can often disrupt operations. Understanding the symptoms helps in identifying issues early. Common symptoms include leaks, unusual noises, or poor performance. These signs indicate potential failures. Addressing them promptly can save time and costs.

When you notice a leak, check the seals and connections. Loose fittings might be the culprit. Unusual noises could stem from air trapped in the pump. Bleeding the system might help. If the pump runs but doesn’t deliver fluid, consider clogs in the inlet or outlet. Awareness of these details is crucial.

Tips: Regular maintenance can prevent many problems. Replace worn parts before they fail. Monitor the pump's performance daily. Know the normal sound levels; anything strange needs attention. Don’t wait too long to address issues. Early intervention can prevent bigger, costly repairs later.

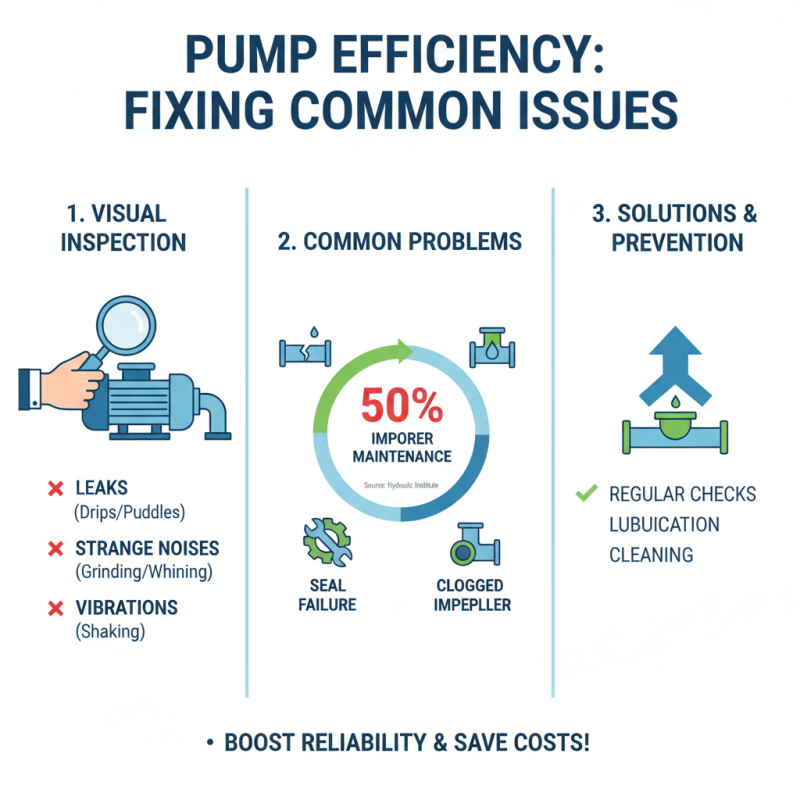

Identifying and fixing common pump issues is a necessity for maintaining efficiency. Start by inspecting the pump visually. Check for leaks, strange noises, or vibrations. These signs often indicate underlying problems. A report from the Hydraulic Institute shows that 50% of pump failures stem from improper maintenance.

Next, listen closely to the pump's operation. Unusual sounds can signify mechanical issues or cavitation. This happens when vapor bubbles collapse in the pump, causing damage. It is crucial to address such sounds early on. Remember, the costs of neglecting these signs can escalate rapidly.

**Tip:** Keep a maintenance log. Record service dates, issues found, and repairs made. This can help you spot trends over time.

If you diagnose a problem, it can sometimes be helpful to consult an expert. However, basic troubleshooting can solve many issues. Check the power supply first to ensure proper voltage. A loose connection can cause the pump to underperform.

**Tip:** Regularly check seals and gaskets for wear. Replacing these components can prevent significant breakdowns down the line.

When it comes to pump repair, having the right tools is crucial. Basic hand tools like wrenches and screwdrivers are essential. They allow you to easily access the pump components. A set of pliers can also help with gripping and twisting hard-to-reach parts. Don’t forget safety goggles and gloves, too, as they protect you from debris.

Specialty tools make repairs more manageable. A multimeter is useful for checking electrical issues. It can help pinpoint faults in the motor. A vacuum gauge might expose pump performance issues. However, not everyone has these tools readily available. That can lead to mishaps during repairs. Take your time to evaluate what you truly need.

Regular maintenance requires even more tools. A good sealant for leaks will save a lot of headaches later. Also, lubricant can prevent sticking parts. Sometimes, it’s beneficial to have replacement parts on hand. If you find yourself replacing same components often, rethink your approach. Adjustments may improve the overall functioning of the pump.

Identifying and fixing common pump failures requires a systematic approach. Start by listening for unusual noises. Rumbling or grinding can indicate mechanical issues. Check the seals for leaks, as water dripping may suggest worn components. Regular inspection can help catch these problems early.

When addressing a malfunction, consider basic repair techniques. For leaks, replacing damaged seals can often rectify the issue. If the pump is running inefficiently, examine the impeller for blockages. Sometimes, disassembly is necessary for a thorough cleaning. Remember, not all repairs can be completed without professional help. Don't hesitate to seek guidance if needed.

Diagnosis is just as important as the repair itself. If you replace a seal but still experience issues, further investigation is warranted. Each pump can behave unexpectedly; it's essential to take notes on each repair attempt. By consistently examining and documenting, potential recurring issues can be identified more easily.

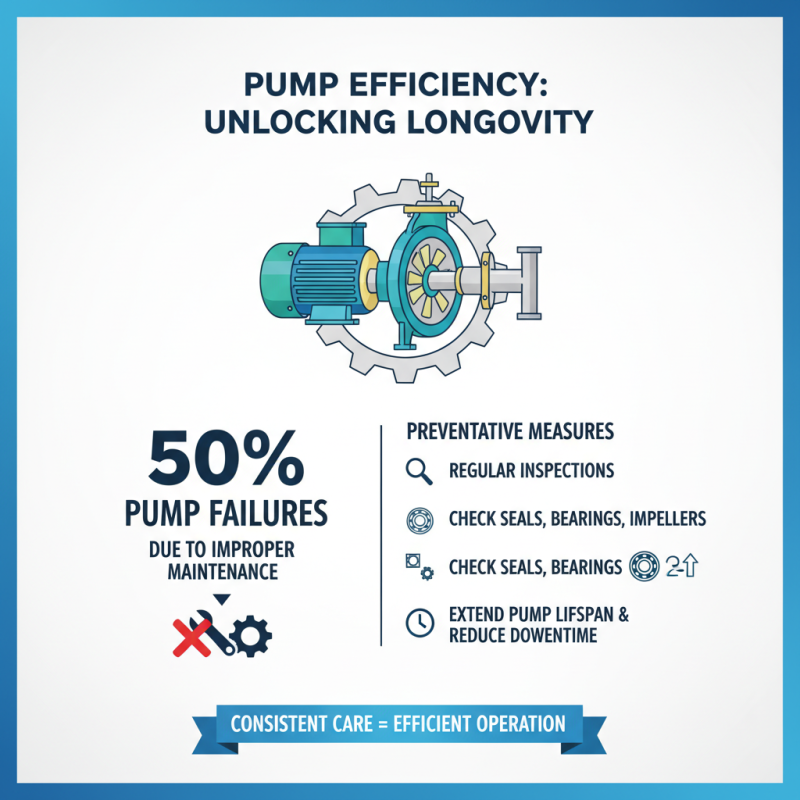

Maintaining pump efficiency is crucial for operational longevity. A recent industry report noted that 50% of pump failures are due to improper maintenance practices. This statistic highlights the need for consistent preventive measures to extend the lifespan of pumps. Regular inspections can identify wear and tear early. Checking seals, bearings, and impellers regularly can prevent costly breakdowns and downtime.

Proper lubrication is another key factor. Nearly 40% of pumps experience failures due to inadequate lubrication. Over-greasing or under-greasing can lead to significant issues. It's essential to follow guidelines to ensure optimal lubrication levels are maintained. Additionally, monitoring pump vibrations is crucial. Excessive vibrations can indicate misalignment or imbalance, leading to further complications.

Training staff on best practices is vital. Operators should be aware of signs suggesting repairs are necessary. They should report unusual noises or fluctuations immediately. Ensuring your team is equipped with knowledge can significantly reduce failure rates. Investing in preventive measures ultimately saves money and resources in the long run.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy