- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

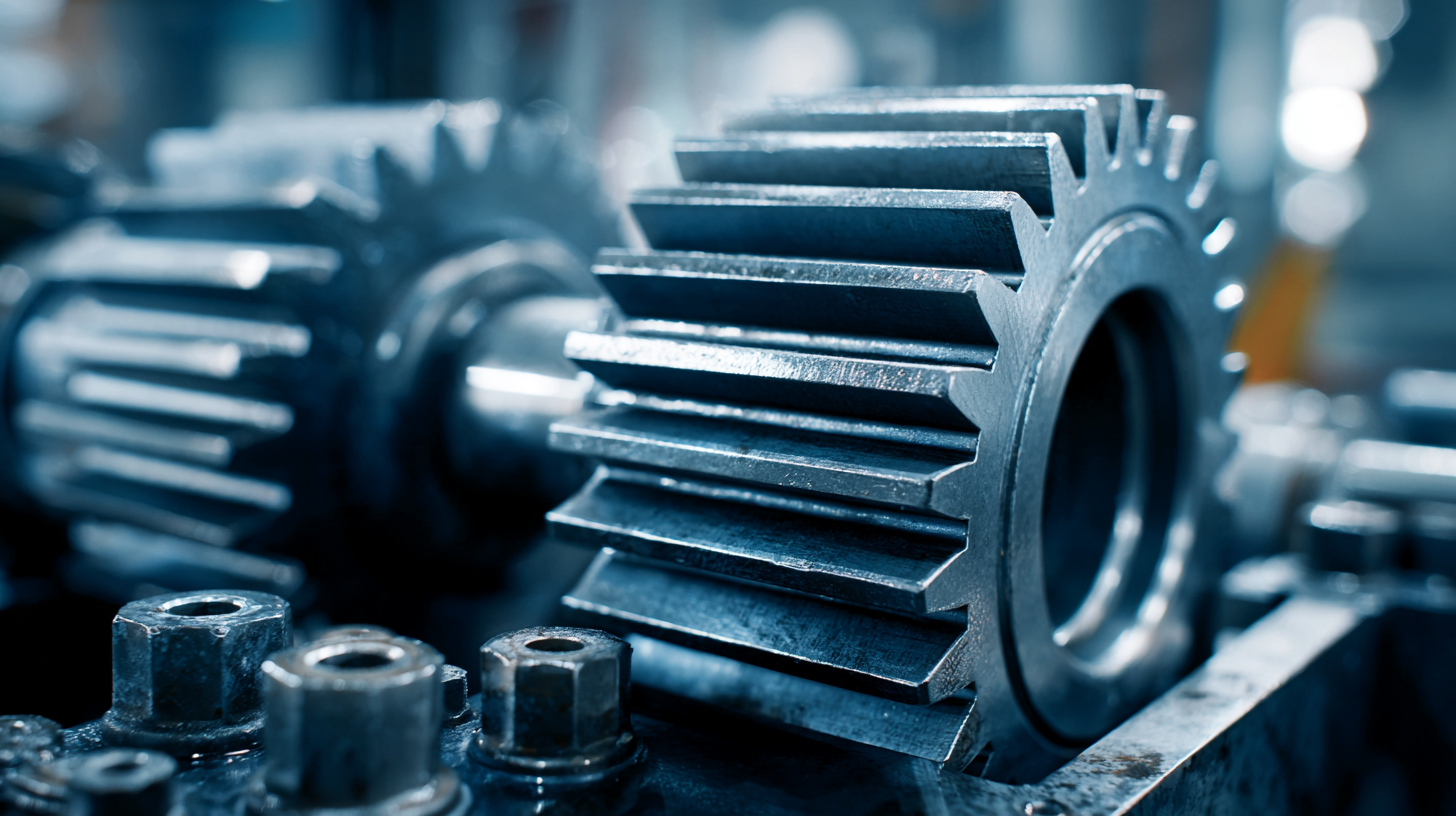

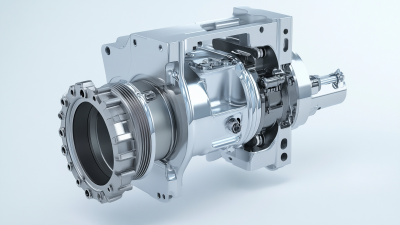

Hydraulic gears play a pivotal role in the efficiency and performance of various machinery across industries. According to the International Society of Automation (ISA), hydraulic systems account for over 30% of the power transmission systems in heavy-duty machinery, emphasizing the significance of hydraulic gear technology.

With the increasing reliance on hydraulic systems for operational efficiency, proper maintenance and understanding of hydraulic gears have become crucial. The latest industry reports indicate that companies implementing regular maintenance protocols can reduce their machine downtime by up to 25%, thereby enhancing productivity.

Furthermore, as the demand for advanced machinery grows, comprehending the nuances of hydraulic gear functionality and maintenance strategies will be essential for industry professionals aiming to optimize performance and prolong equipment lifespan.

With the increasing reliance on hydraulic systems for operational efficiency, proper maintenance and understanding of hydraulic gears have become crucial. The latest industry reports indicate that companies implementing regular maintenance protocols can reduce their machine downtime by up to 25%, thereby enhancing productivity.

Furthermore, as the demand for advanced machinery grows, comprehending the nuances of hydraulic gear functionality and maintenance strategies will be essential for industry professionals aiming to optimize performance and prolong equipment lifespan.

Hydraulic gears play a crucial role in modern machinery, significantly impacting performance across various applications. Their design is optimized for efficiency in industries like construction, where robust gear systems are essential. The hydraulic gear pump market is projected to reach USD 14.6 billion by 2035, growing at a compound annual growth rate (CAGR) of 4.7%. This increase is driven by rising demands for construction and industrial equipment, emphasizing the importance of high-performing hydraulic gears in meeting industrial needs.

Hydraulic gears play a crucial role in modern machinery, significantly impacting performance across various applications. Their design is optimized for efficiency in industries like construction, where robust gear systems are essential. The hydraulic gear pump market is projected to reach USD 14.6 billion by 2035, growing at a compound annual growth rate (CAGR) of 4.7%. This increase is driven by rising demands for construction and industrial equipment, emphasizing the importance of high-performing hydraulic gears in meeting industrial needs.

Understanding the different types of hydraulic gears, such as gear pumps and motors, is vital for enhancing machine performance. The market for lubricants is also anticipated to soar to USD 204.10 billion by 2030, highlighting the necessity for effective gear oils that ensure reliability and minimize equipment downtime. Utilizing specialized lubricants in hydraulic gear systems can prevent wear and tear, ultimately leading to longer service life and better operational efficiency.

As the industry evolves, prioritizing the right hydraulic gear components and maintenance strategies will be key to sustaining optimal machinery performance.

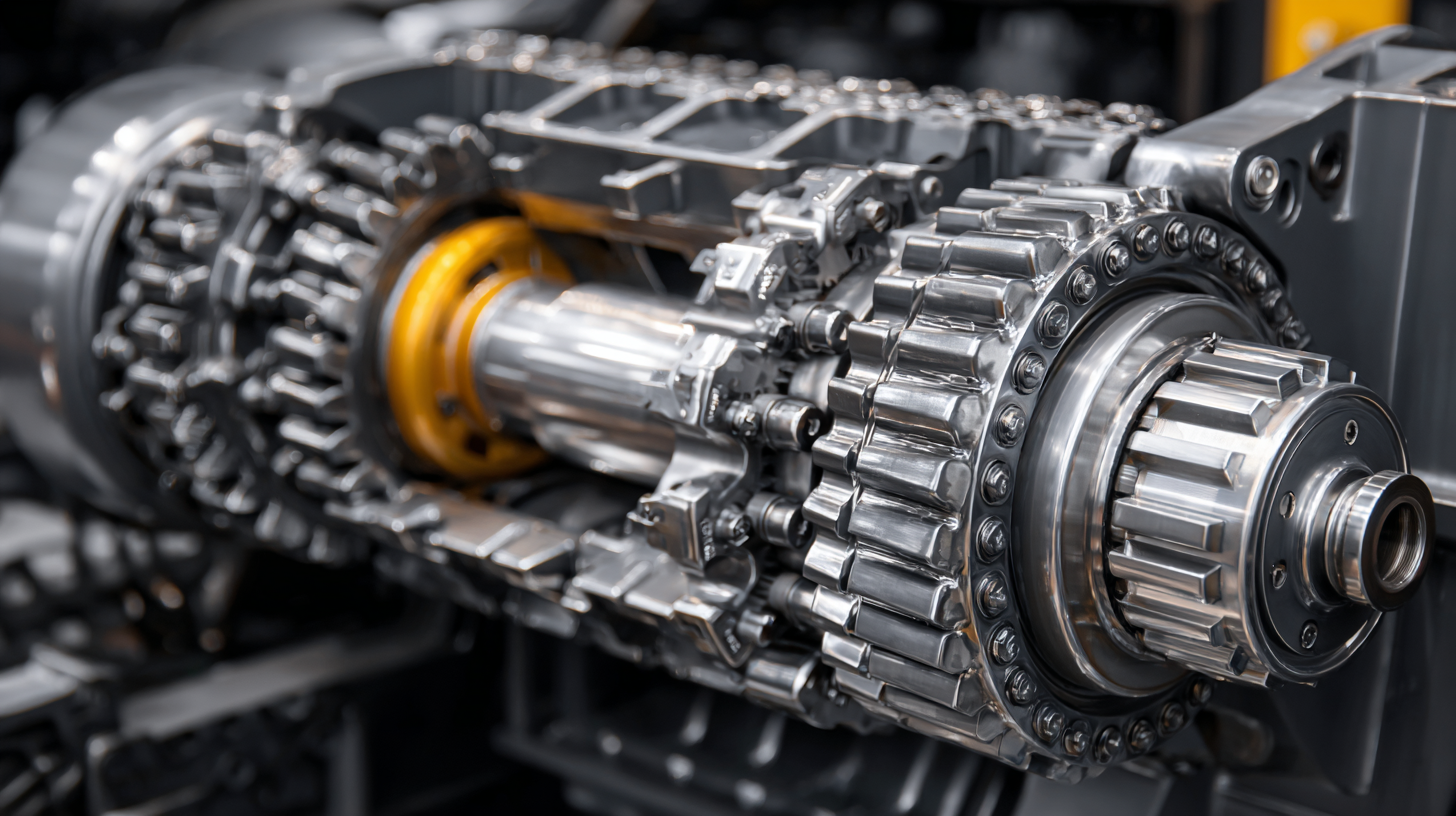

Hydraulic gears play a crucial role in enhancing the performance of modern machinery, with several benefits that make them a preferred choice across various industries. One of the key advantages is their ability to transmit power efficiently, allowing for smooth operation even under demanding conditions. This efficiency reduces energy consumption, leading to lower operational costs and minimizing the environmental impact of machinery.

Another significant benefit of hydraulic gears is their superior load-carrying capacity. Unlike traditional mechanical gears, hydraulic systems can handle greater loads without compromising performance. This robustness is particularly important in heavy-duty applications, where reliability and durability are essential. Additionally, hydraulic systems offer greater flexibility in design, enabling engineers to configure systems tailored to specific machinery needs, thus optimizing overall functionality.

Moreover, hydraulic gears require less maintenance compared to their mechanical counterparts. The smooth operation reduces wear and tear, and the use of hydraulic fluids can aid in cooling and lubrication, further extending the lifespan of components. This low maintenance requirement not only enhances productivity but also reduces downtime, allowing operations to run more smoothly and efficiently.

| Benefit | Description | Impact on Machinery | Maintenance Tips |

|---|---|---|---|

| Power Density | Hydraulic gears provide high power output in a compact size. | Enhances overall machine efficiency and space utilization. | Regular fluid checks and filtration maintenance. |

| Load Handling | Capable of managing heavy loads effectively. | Reduces strain on machinery components. | Inspect for leaks and ensure seals are intact. |

| Flexibility | Adaptable to various machinery designs and applications. | Allows for customized machinery solutions. | Ensure appropriate hydraulic fluids are used. |

| Durability | Built to withstand harsh environments and conditions. | Increases the lifespan of machinery. | Regularly check fittings and hoses for wear. |

| Cost-Effectiveness | Provides effective solutions with lower operational costs. | Impacts ROI positively for machinery owners. | Plan preventive maintenance to lower unexpected costs. |

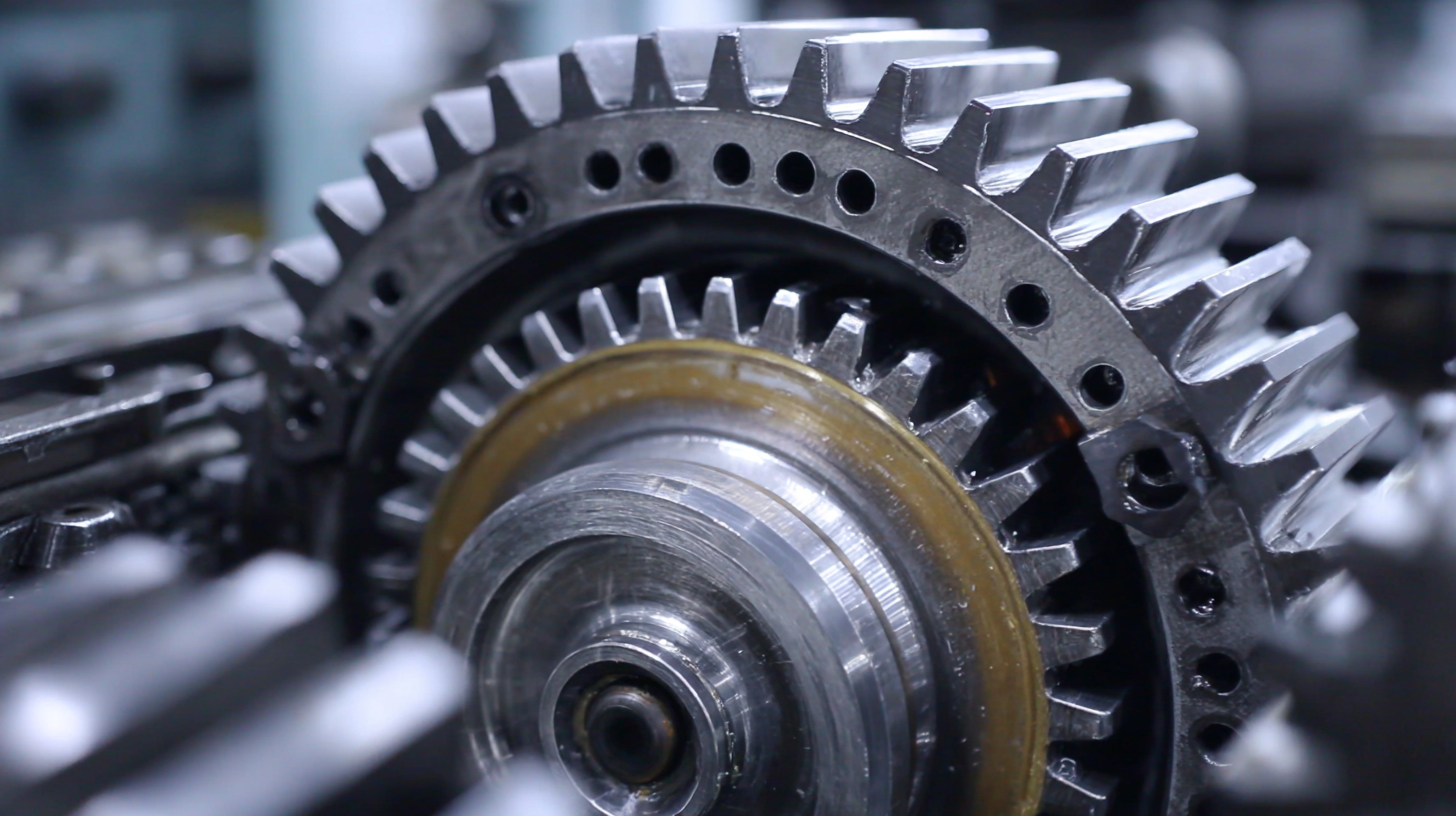

Hydraulic gears play a critical role in enhancing the performance of machinery by ensuring

smooth and efficient power transmission. To maximize their lifespan and functionality,

regular maintenance is essential. The first step in effective maintenance is to ensure

proper lubrication. Using the right type and amount of hydraulic fluid not only minimizes

friction but also helps dissipate heat, preventing potential damage.

Another vital tip involves inspecting seals and hoses regularly for wear and leaks.

Addressing any signs of deterioration immediately can prevent costly repairs down the line.

Additionally, keeping the hydraulic system clean is crucial. Contaminants can lead

to significant performance issues, so routine flushing and replacing of filters should be incorporated into your

maintenance schedule. Finally, conducting regular performance checks, including

monitoring pressure levels and flow rates, ensures that any discrepancies

are addressed before they lead to major failures. By following these essential tips, you can enhance the

performance and longevity of hydraulic gears in your machinery.

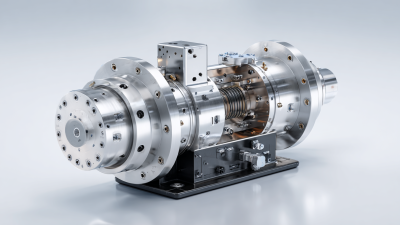

Hydraulic fluids play a critical role in the performance and maintenance of hydraulic gears in machinery. Choosing the right type of hydraulic fluid can significantly impact operational efficiency and equipment longevity. According to a report by the Hydraulic Institute, improper fluid choice can lead to a 10-15% decrease in system efficiency, emphasizing the importance of selecting the appropriate fluid for specific applications. Factors such as temperature stability, viscosity, and lubricating properties must be taken into account to ensure optimal performance.

When selecting hydraulic fluids, it is essential to consider the operating environment and the specific demands of the machinery. For instance, fluids with a high viscosity index exhibit minimal changes in viscosity with temperature fluctuations, making them ideal for systems that operate in varying conditions. As noted in a study published by the American Society of Mechanical Engineers, the right hydraulic fluid can extend the life cycle of machinery components by up to 30%, reducing maintenance costs and downtime. Investing time in understanding the properties of hydraulic fluids can lead to improved efficiency and reduced long-term expenses for machinery operators.

Hydraulic gears are crucial for the efficient performance of various machinery. However, like any mechanical system, they can experience issues that may hinder their operation. Here are three common problems you might encounter with hydraulic gears and how to troubleshoot them.

1. Fluid Leakage: This can originate from worn seals or loose fittings. To address this, regularly inspect the seals for signs of wear and consider replacing them if necessary. Additionally, tighten any loose connections to prevent further leakage. Tip: Regular maintenance checks can help identify potential leaks early before they escalate into more significant problems.

2. Overheating: This can cause premature wear and tear. This often results from insufficient hydraulic fluid levels or a dirty filter. To troubleshoot, check the fluid levels and top them off as needed. Also, replace or clean the filter to ensure proper coolant circulation. Tip: Implement a routine where you monitor the temperature of your hydraulic system during operation, which can signal if something is amiss.

3. Unusual Noise: This can indicate internal damage within the gear system. Any grinding or rattling sounds should be investigated promptly. Inspect the gears for wear and tear, and listen for any abnormal sounds during operation. If noise persists, consult a professional for a deeper examination. Tip: Keeping a log of operational sounds can help in identifying changes over time, aiding quick diagnosis of potential issues.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy