- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In the rapidly evolving world of hydraulic systems, "Gear Hydraulic" technologies have increasingly become the backbone of various industrial applications, from manufacturing to automotive. According to a recent market research report by Fortune Business Insights, the global hydraulic market is projected to reach $54.95 billion by 2028, with Gear Hydraulic systems playing a pivotal role in this growth due to their efficiency and reliability. Companies are recognizing the importance of selecting the right hydraulic gear systems, as they are integral to optimizing operational performance and reducing machinery downtime.

As global buyers navigate the complexities of integrating Gear Hydraulic solutions into their operations, understanding the various available options becomes crucial. The International Journal of Fluid Power highlights that advancements in Gear Hydraulic design have led to improvements in power density and durability, making these systems more appealing than ever. This comprehensive analysis aims to provide an in-depth overview of the Gear Hydraulic options available to buyers worldwide, equipping them with the insights needed to make informed decisions in a competitive market landscape.

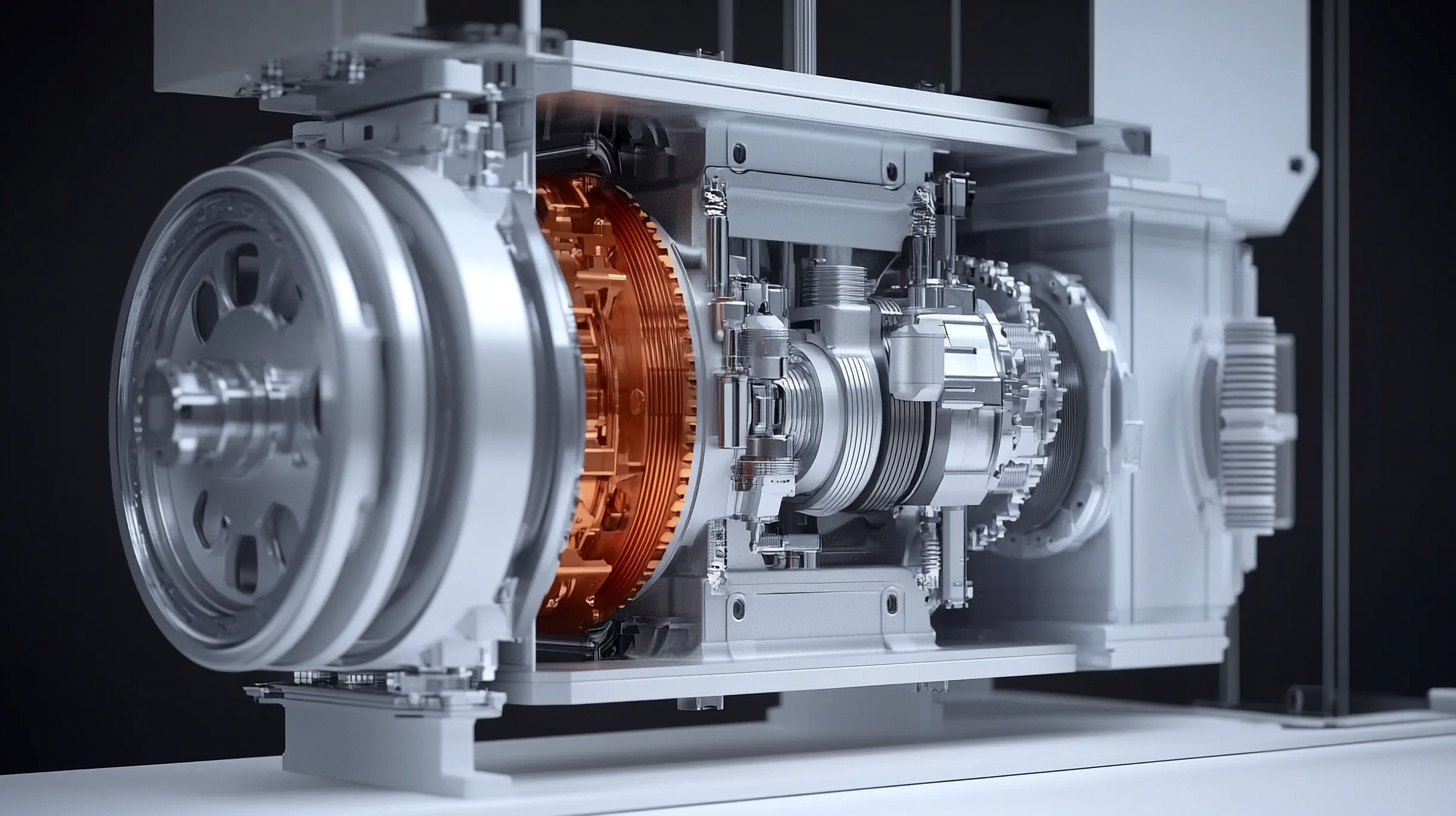

The hydraulic system market for gear applications has expanded significantly, offering various options tailored to diverse industries. In recent years, a shift towards more efficient and compact gear hydraulic systems has been observed, driven by advancements in technology and increasing demand for precision engineering. According to a recent industry report, the global hydraulic systems market is projected to reach $45 billion by 2026, growing at a CAGR of 5.9% from 2021. This growth reflects the rising adoption of advanced technologies and automation in various sectors, emphasizing the need for reliable and innovative hydraulic solutions. When exploring the types of gear hydraulic systems, one can categorize them into several key types: spur gear pumps, helical gear pumps, and bevel gear pumps, each designed for specific applications. Spur gear pumps are renowned for their simplicity and robustness, making them ideal for applications requiring steady flow and moderate pressure. On the other hand, helical gear pumps offer higher efficiency due to their design, which minimizes internal losses, making them suitable for high-performance tasks. Additionally, bevel gear pumps provide advantageous torque and speed conversion, commonly used in more complex machinery setups. As industries increasingly focus on sustainability and energy efficiency, many hydraulic systems are now being designed with eco-friendly materials and technologies. For instance, innovative hydraulic fluids that reduce environmental impact while enhancing performance are becoming standard. With a variety of gear hydraulic options available, global buyers can select systems that not only meet their operational needs but also align with their sustainability goals, reflecting a broader trend towards responsible manufacturing practices in the hydraulic systems sector.

When selecting gear hydraulic options, buyers must consider several key factors to ensure they make an informed decision that aligns with their specific needs. Firstly, understanding the application requirements is crucial. Different industries, such as construction, agriculture, and manufacturing, demand varying levels of power, efficiency, and operational reliability. By defining the application, buyers can narrow down the options that best suit their workload and environmental conditions.

Another important aspect is the selection of the right materials and construction quality. Gear hydraulic systems operate under significant pressure and demanding conditions, making it essential to choose options made from robust materials that can withstand wear and tear over time. Buyers should consider the type of seals, housing materials, and any protective coatings that can enhance durability and performance.

Additionally, compatibility with existing systems cannot be overlooked. Buyers should ensure that the gear hydraulic options they are considering can integrate seamlessly with their current machinery and hydraulic systems. This factor is critical not only for performance efficiency but also for minimizing installation costs and downtime during transition phases. Finally, evaluating suppliers’ support, warranty options, and service availability will provide peace of mind and ensure long-term satisfaction with the purchased hydraulic gear systems.

The global hydraulic gear market has experienced consistent growth over the past several years, driven by increasing demand from various sectors such as construction, manufacturing, and automotive. According to a report by Market Research Future, the hydraulic gear market is projected to reach USD 5.8 billion by 2025, growing at a CAGR of approximately 5.3% during the forecast period. This growth has prompted manufacturers around the world to diversify their offerings, creating a competitive landscape that presents both challenges and opportunities for global buyers.

In a comparative review of leading global manufacturers, it is essential to highlight key players such as Bosch Rexroth, Parker Hannifin, and Eaton Corporation. Bosch Rexroth, recognized for its innovation in hydraulic technology, offers a wide range of gear pumps and motors tailored to enhance efficiency and performance. Their products are backed by rigorous testing and meet international standards, ensuring reliability in demanding applications. On the other hand, Parker Hannifin emphasizes their commitment to sustainability, integrating eco-friendly materials into their hydraulic systems, which aligns with the industry's shift towards greener solutions.

Eaton Corporation stands out for its advanced hydraulic gear designs that focus on reducing energy consumption. Their latest reports indicate that improved gear efficiency can lead to a 20% reduction in operational costs for end-users. This positions Eaton as a critical player for buyers looking to balance performance with cost-effectiveness. By examining these manufacturers and understanding their distinct offerings, global buyers can make informed decisions in selecting hydraulic gear solutions that meet their specific operational needs.

The field of hydraulic solutions is currently experiencing significant innovations that cater to the demanding needs of global buyers. As the industrial hydraulic equipment market expands, projected to reach USD 52.6 billion by 2033 with a 5.7% CAGR, companies are driven to develop technologies that enhance efficiency, performance, and sustainability. Central to this transformation are advancements in filter designs and the introduction of sustainable hydraulic components which are crucial in protecting against contamination and ensuring system reliability.

Recent advancements in hydraulics will be prominently showcased at bauma 2025, where leading companies in the industry will present their cutting-edge technologies. This event serves as a platform for highlighting innovative products that meet stringent industry requirements while addressing the crucial need for efficient fluid power systems. The spotlight will also focus on mobile hydraulic equipment, where a competitive market landscape is marked by a projected CAGR of 6.1%, showcasing the increasing importance of hydraulic pumps, valves, and other components.

Furthermore, the push towards technological renewal is characterized by a collective desire for more efficient and sustainable systems, creating a ripple effect throughout the hydraulics industry. As companies optimize their product offerings to meet these evolving demands, the focus on innovative trends and technologies remains paramount, fostering an environment ripe for growth and development in the global hydraulic solutions market.

When considering gear hydraulic systems, cost-effectiveness plays a crucial role in the decision-making process for global buyers. Budgeting for these systems involves not only the initial purchase price but also long-term maintenance costs that can significantly impact overall expenditures. Buyers must take into account the various factors that contribute to these costs, including the quality of materials used in the hydraulic components, the manufacturer's reputation, and the system's anticipated lifespan.

Maintenance is often viewed as an afterthought; however, a well-planned maintenance strategy can prevent costly downtimes and repairs. Investing in high-quality components may lead to a higher upfront cost, but they often reduce the frequency of repairs and the need for replacements, ultimately saving money in the long run. Additionally, understanding the recommended maintenance schedules and procedures from manufacturers can assist buyers in creating a realistic budget that accommodates routine inspections and necessary upkeep.

Moreover, manufacturers often provide warranties and service contracts that can be beneficial for budgeting purposes. These agreements can offer predictable costs over the lifespan of the equipment and should be factored into any cost-effectiveness assessment. By evaluating the total cost of ownership, including both purchase and maintenance expenses, global buyers can make informed decisions that align with their financial goals while ensuring the efficiency and longevity of their gear hydraulic systems.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy