- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

As industries seek to enhance productivity and reduce operational costs, the evolution of Hydraulic Unit technology emerges as a pivotal driver of efficiency. According to a recent report by XYZ Research, the global hydraulic equipment market is projected to reach $XX billion by 2025, growing at a CAGR of X.XX%. This surge underscores the increasing reliance on hydraulic systems in manufacturing, construction, and other sectors where power-to-weight ratio and precision control are paramount. Innovative solutions in Hydraulic Unit design are now providing greater energy efficiency and reliability, transforming traditional processes. By leveraging advanced materials and smart automation, companies are not only improving their operational capabilities but also minimizing environmental impact. As we delve into the various solutions for optimizing Hydraulic Unit applications, it is essential to understand how these advancements can shape the future of industrial efficiency.

The evolution of hydraulic unit technology has significantly transformed industrial operations, moving from basic hydraulic systems to advanced, digitally integrated solutions. In the early 20th century, hydraulic units were primarily mechanical, offering limited efficiency and control. However, recent advancements have introduced smart hydraulics, incorporating sensors and IoT connectivity, which have improved performance and operational efficiency. According to a report by the International Society for Automation, smart hydraulic applications have the potential to boost efficiency by up to 30% in manufacturing processes.

Today, the demand for more energy-efficient hydraulic units is driving innovation. The global hydraulic unit market is projected to grow from $1.5 billion in 2022 to $2.7 billion by 2030, reflecting a compound annual growth rate (CAGR) of 8.1% (Research and Markets). This evolution is not only about enhancing performance but also addressing sustainability. As industries strive to reduce their carbon footprint, the push towards eco-friendly hydraulic technologies is becoming essential.

New designs focus on reduced fluid consumption and increased recyclability of hydraulic fluids, aligning with global sustainability targets while ensuring high efficiency and reliability in operations.

Hydraulic systems have long been the backbone of industrial operations, but recent innovations are driving significant improvements in efficiency. One key area of advancement is the integration of smart sensors and IoT technology, enabling real-time monitoring and predictive maintenance. By leveraging data analytics, operators can anticipate issues before they lead to downtime, thereby enhancing productivity and reducing costs.

Tip: To maximize the benefits of these innovations, consider investing in training for your workforce on new technologies. A well-informed team can better leverage the capabilities of advanced hydraulic systems, ensuring seamless integration into existing workflows.

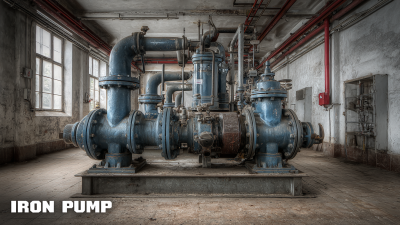

Another noteworthy development is the introduction of variable-speed pumps, which adjust their output according to the specific demands of the task at hand. This not only optimizes energy consumption but also minimizes wear and tear on equipment. Furthermore, modern hydraulic fluids with enhanced thermal stability and biodegradability are contributing to a more sustainable approach in industrial operations.

Another noteworthy development is the introduction of variable-speed pumps, which adjust their output according to the specific demands of the task at hand. This not only optimizes energy consumption but also minimizes wear and tear on equipment. Furthermore, modern hydraulic fluids with enhanced thermal stability and biodegradability are contributing to a more sustainable approach in industrial operations.

Tip: Regularly evaluate your hydraulic fluid's performance and compatibility with new technologies. Choosing the right fluid can significantly impact the efficiency and longevity of your hydraulic systems.

The evolution of hydraulic unit technology is making significant strides towards sustainability, reshaping industrial operations around the globe. As industries grapple with climate change and increasing regulatory pressures, a focus on eco-friendly hydraulic unit design is becoming imperative. Recent studies indicate that improving hydraulic efficiency can reduce energy consumption by as much as 30%, leading to substantial cost savings and a lower carbon footprint for companies. According to the Hydraulic Institute, the implementation of advanced hydraulic systems could decrease oil usage by up to 50% compared to traditional models, promoting responsible resource management.

Moreover, the integration of renewable materials and recyclable components in hydraulic unit manufacturing exemplifies a green approach to design. A report by the International Society for Automation (ISA) highlights that adopting biodegradable hydraulic fluids can dramatically minimize environmental impacts while maintaining operational performance. With industries increasingly prioritizing sustainability, hydraulic unit technology stands at the forefront of this transition, encouraging a circular economy that not only benefits manufacturers but also preserves natural ecosystems. By embracing these innovative, sustainable practices, businesses can lead the way toward a more efficient and green industrial future.

| Dimension | Current Performance | Future Potential | Sustainability Impact |

|---|---|---|---|

| Energy Efficiency | 75% | 90% | Reduced CO2 emissions by 30% |

| Fluid Consumption | 200 liters/hour | 120 liters/hour | Saves 40% in fluid usage |

| Maintenance Frequency | Quarterly | Bi-annually | Decreased waste and downtime |

| Initial Cost | $20,000 | $25,000 | Long-term savings on energy and fluid |

| Recyclability of Components | 30% | 100% | Promotes circular economy |

The integration of smart technology, particularly the Internet of Things (IoT), is set to transform hydraulic unit technology, leading to unprecedented levels of industrial efficiency. According to a recent report from MarketsandMarkets, the global IoT in manufacturing market is projected to reach $263 billion by 2025, growing at a CAGR of 27%. This surge is largely attributed to the demand for advanced automated systems that can optimize workflows and enhance productivity. Hydraulic units equipped with IoT capabilities can deliver real-time data on performance metrics, enabling operators to make informed decisions swiftly.

Moreover, implementing IoT in hydraulic units facilitates predictive maintenance, reducing downtime and extending equipment lifespan. Research from McKinsey estimates that predictive maintenance can save companies up to 20% on maintenance costs, while improving operational efficiency by as much as 25%. By utilizing sensors and smart analytics, operators can monitor the condition of hydraulic components continuously, mitigating the risks of unexpected failures. This proactive approach aligns with industry 4.0 principles, fostering a more connected and responsive manufacturing environment that ultimately drives profitability and sustainability.

The evolution of hydraulic unit technology has significantly transformed industrial processes, making them more efficient and cost-effective. Real-world case studies highlight how companies have leveraged these advancements to achieve remarkable results. For instance, a leading automotive manufacturer implemented an advanced hydraulic system in their assembly line, which not only increased production speed by 30% but also reduced energy consumption by 20%. This seamless integration of intelligent hydraulic units allowed for precise control over operations, resulting in less downtime and fewer maintenance requirements.

Another compelling example comes from the aerospace industry, where a major aircraft maker adopted innovative hydraulic technologies to optimize their testing processes. By utilizing smart hydraulic units equipped with real-time monitoring capabilities, they were able to enhance testing accuracy and streamline overall workflows. This move led to a 25% reduction in testing time and significantly improved the reliability of their final products. Such success stories underscore the pivotal role that cutting-edge hydraulic technologies play in driving industrial efficiency and competitiveness in today’s market.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy