- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In the ever-evolving landscape of modern machinery, hydraulic gears are emerging as a pivotal technology enhancing efficiency and performance across various sectors. According to a recent industry analysis by Research and Markets, the global hydraulic gear market is expected to reach a valuation of over $10 billion by 2025, driven by robust demand in construction, agricultural, and manufacturing equipment. Hydraulic gears enable precise control of movement and force, making them indispensable for applications requiring high torque and compact design. Their ability to operate in harsh environments and deliver exceptional power-to-weight ratios further solidifies their relevance in contemporary engineering solutions. This blog presents seven essential benefits of hydraulic gears, illustrating their critical role in optimizing machinery performance and advancing operational capabilities.

Hydraulic gears have become increasingly vital in various industrial applications due to their unique advantages in power transmission and efficiency. According to a recent report by the International Journal of Engineering Research and Applications, hydraulic systems can achieve up to 90% efficiency in energy transfer. This remarkable efficiency minimizes energy waste and optimizes performance, especially in heavy machinery and equipment that require reliable power under demanding conditions.

In addition to efficiency, hydraulic gears offer exceptional torque multiplication, making them ideal for applications that involve heavy lifting or precise movement. A study by the American Society of Mechanical Engineers highlights that hydraulic systems can provide a torque output that is significantly higher than that of traditional gear systems, with ratios often exceeding 3:1. This capability translates to improved operational performance in industries such as construction, mining, and manufacturing, where robust and responsive machinery is crucial for productivity and safety. The integration of hydraulic gears not only enhances the capabilities of modern machinery but also contributes to more streamlined and efficient operational processes across various sectors.

Hydraulic gears have revolutionized modern machinery by significantly enhancing efficiency and performance. According to a recent report by the International Journal of Fluid Power, systems utilizing hydraulic gears can achieve efficiency rates of 85-90%, compared to only 70-75% with traditional mechanical systems. This superior efficiency translates to improved power-to-weight ratios, allowing machines to operate more effectively under heavy loads and demanding conditions.

One key advantage of hydraulic gears is their ability to provide variable speed and torque outputs. This adaptability is essential in industries such as construction and manufacturing, where operational demands can change rapidly. A study published by the Society of Automotive Engineers indicates that machines utilizing hydraulic gear systems experience a 30% increase in productivity due to their responsive nature.

**Tips:** To maximize the benefits of hydraulic gears, routine maintenance is crucial. Regular fluid checks and filtering can prevent contamination, which is vital for sustaining efficiency. Additionally, consider integrating advanced hydraulic controls that allow for better load management and responsiveness, further enhancing machine performance in variable conditions.

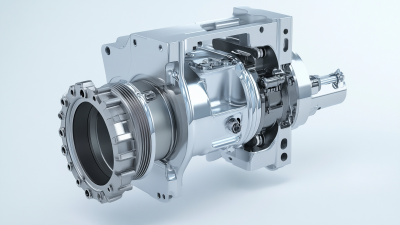

Hydraulic gears have become an essential component in modern machinery, owing to their unmatched durability and reliability. The robust nature of hydraulic systems allows them to withstand high stress and varying operating conditions, which is crucial in industries that demand precision and endurance. Unlike traditional mechanical gears, hydraulic gears can effectively absorb shock loads, reducing wear and tear, which translates to longer service life and minimized maintenance costs. This resilience ensures that machinery operates smoothly, even under heavy loads or in challenging environments.

In addition to their durability, hydraulic gears provide a level of reliability that is indispensable in many applications. Their consistent performance means that operators can rely on them to deliver the required torque and power without unexpected failures. This reliability not only enhances productivity but also contributes to overall safety, as equipment malfunctions can lead to hazardous situations. Given these long-term benefits, investing in hydraulic gears is a strategic choice for businesses looking to enhance the performance and longevity of their machinery. By choosing hydraulic solutions, industries can enjoy peace of mind knowing that their equipment is built to last, making it a worthy investment for future operations.

| Benefit | Description | Long-Term Impact |

|---|---|---|

| Durability | Hydraulic gears are designed to withstand significant operational stresses, providing greater longevity than traditional gear systems. | Reduces frequency of replacements and maintenance costs. |

| Reliability | Hydraulic gears provide consistent performance even under harsh conditions, minimizing downtime. | Ensures steady output and efficiency in operations. |

| High Efficiency | They enable high torque transmission and speed regulation with lower energy consumption. | Contributes to reduced operational costs over time. |

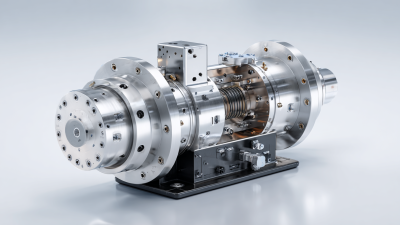

| Compact Design | Hydraulic gears can be designed to occupy less space, allowing for more versatile machinery layouts. | Facilitates innovative engineering solutions and compact machinery. |

| Noise Reduction | Hydraulic systems operate more quietly than mechanical gear systems, leading to improved working environments. | Enhances workplace safety and comfort. |

| Adaptability | Hydraulic gears can be easily adjusted to suit different applications and settings. | Allows for flexibility in machinery use and applications. |

| Lower Maintenance Costs | With fewer mechanical parts and higher reliability, maintenance is less frequent and less costly. | Maximizes long-term savings and productivity. |

Hydraulic gears have become indispensable in modern machinery, providing exceptional versatility across various applications. From construction equipment to agricultural machinery, hydraulic systems are designed to deliver powerful performance in a compact form. The ability to adjust flow and pressure allows hydraulic gears to adapt seamlessly to different operational demands, making them ideal for tasks that require varying levels of speed and torque. This adaptability ensures that machinery can operate efficiently under different loads and conditions, enhancing productivity and reducing downtime.

Furthermore, the integration of hydraulic gears into diverse machinery types promotes energy efficiency. These systems can transfer energy more effectively than mechanical gears, minimizing power loss and maximizing output. As industries increasingly prioritize sustainability, the use of hydraulic gears contributes to reduced energy consumption and emissions. Whether in excavators, forklifts, or lawn maintenance equipment, hydraulic gears enable manufacturers to create compact, powerful machines that provide reliable performance while also meeting environmental standards. This multifaceted functionality showcases the crucial role hydraulic gears play in advancing modern machinery across multiple sectors.

When it comes to modern machinery, hydraulic gears stand out for their cost-effectiveness, particularly in reducing maintenance and operational expenses. Unlike traditional mechanical systems, hydraulic gears are designed to handle heavy loads and high torque with less stress on components. This not only extends the lifespan of machinery but also alleviates the frequency and cost of repairs. By minimizing wear and tear, businesses can allocate their resources more efficiently, turning their focus toward production rather than maintenance.

Additionally, hydraulic gears offer significant advantages in energy efficiency. Their ability to transmit power smoothly means that machinery operates at optimal performance, consuming less energy over time. This reduced energy usage translates to lower utility bills, making hydraulic gears an economically sound choice for both short-term operations and long-term investment. As industries strive for sustainability and cost savings, integrating hydraulic gears can lead to substantial financial benefits while enhancing overall operational efficiency.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy