- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

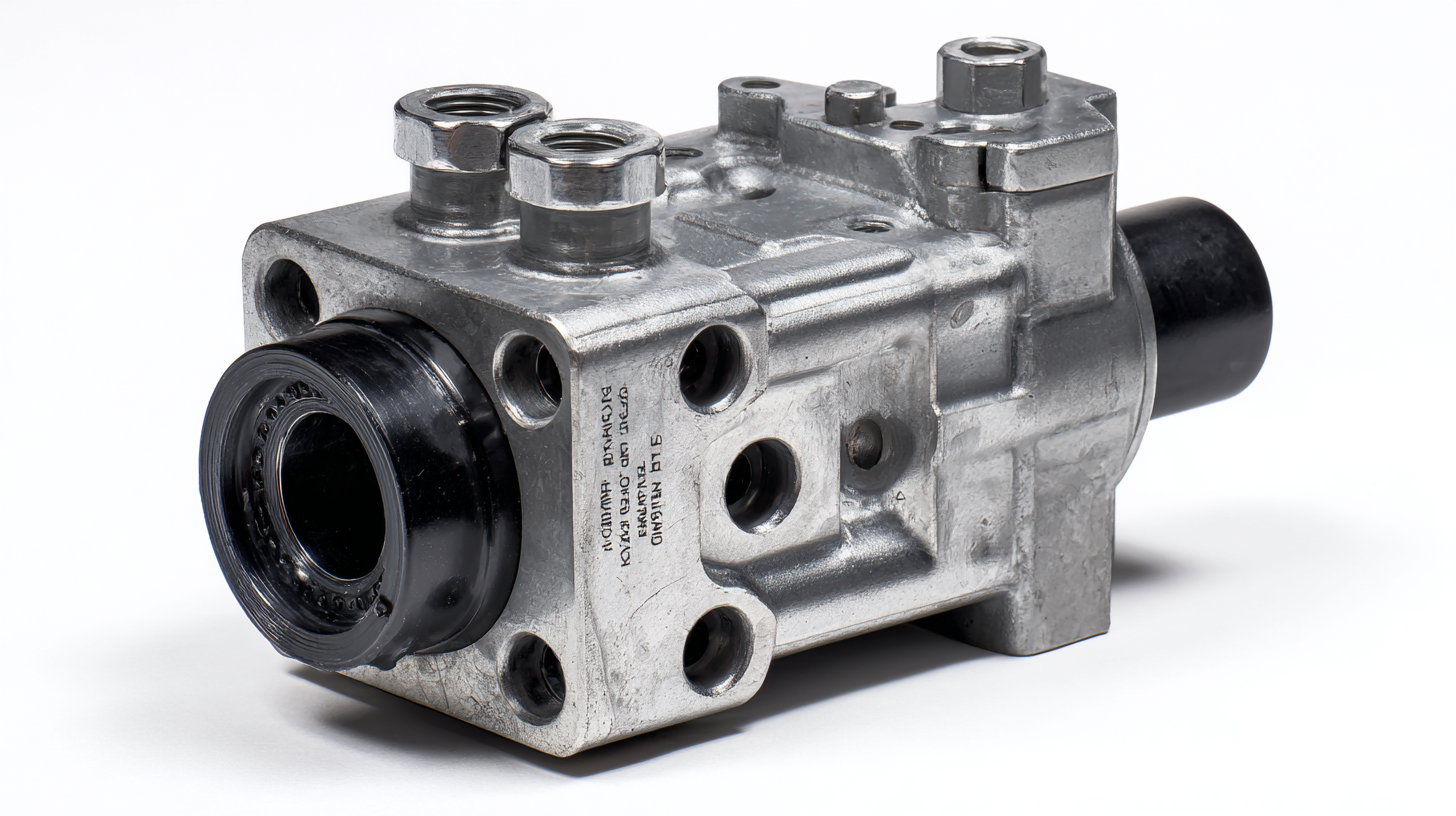

In today's industrial landscape, the efficiency and reliability of hydraulic systems are crucial for optimal performance. According to the latest market research report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 34.78 billion by 2026, growing at a CAGR of 5.3% from 2021 to 2026. Central to this growth is the importance of selecting the right Hydraulic Pump Parts, which not only enhance operational efficiency but also reduce maintenance costs and downtime. Understanding the intricate technical specifications and compatibility of these components is essential for businesses aiming to optimize their hydraulic systems. This ultimate guide will delve into the critical factors to consider when choosing Hydraulic Pump Parts, providing actionable insights and expert tips to meet your industrial needs effectively.

When it comes to selecting hydraulic pump parts for industrial applications, understanding the essential features that contribute to quality is paramount. High-quality hydraulic pump parts significantly enhance the efficiency and longevity of your hydraulic systems. Key features to consider include the material composition, sealing mechanisms, and the precision of machining. According to a report by the Hydraulic Institute, using components made from advanced materials such as high-strength steel can lead to a reduction in pump failures by as much as 30%. This reduction is crucial for maintaining productivity in industrial operations.

**Tip:** Always check for certifications and standards compliance, such as ISO 9001, which indicates a commitment to quality in manufacturing processes.

Additionally, the sealing technology employed in hydraulic pumps is vital for preventing leaks and ensuring optimal performance. Advanced seals made from materials like polyurethane or fluorocarbon can withstand higher pressures and temperatures, reducing the risk of costly downtime. The National Fluid Power Association (NFPA) emphasizes that proper seal selection can improve system efficiency by up to 25%.

**Tip:** Consider investing in parts with enhanced sealing features to maximize performance and lifespan.

With the right components, including durable materials and advanced sealing technologies, businesses can ensure their hydraulic systems operate at peak efficiency and reliability.

| Feature | Description | Importance | Quality Indicators |

|---|---|---|---|

| Material | Type and quality of materials used in construction | High durability and resistance to wear | Steel or aluminum construction, corrosion resistance |

| Pump Type | Classification of pump such as gear, vane, or piston | Matches application needs and efficiency requirements | Flow rates, pressure ratings, and operational efficiency |

| Sealing Mechanism | System to prevent fluid leakage | Critical for preventing loss of power and efficiency | Quality seals, operating temperature ranges |

| Pressure Rating | Maximum pressure the pump can handle safely | Ensures pump can operate under expected conditions | Tested pressure limits, certification stamps |

| Maintenance Requirements | Frequency and ease of maintenance needed | Minimizes downtime and maintenance costs | User manuals, service intervals, warranty information |

When selecting hydraulic pump components, the significance of material selection cannot be overstated. The performance and longevity of hydraulic systems largely depend on the materials chosen for their critical parts, especially in high-stress environments. For instance, hydraulic piston pumps, which are integral to the hydraulic transmission system, require materials that withstand tremendous pressure, corrosion, and wear. Utilizing high-strength steels and advanced alloys can enhance the durability and efficiency of these pumps, ensuring they operate reliably over extended periods.

In the quest for innovation, industries are shifting towards lightweight materials that do not compromise on strength. The exploration of new lightweight alloys is pivotal, especially in sectors like automotive engineering, where reducing weight is essential for improving fuel efficiency. These advanced materials also provide better thermal management and resistance to fatigue, which are crucial in maintaining the integrity of hydraulic components. As engineering continues to evolve, focusing on the right material selection will play a crucial role in optimizing hydraulic systems for a wide range of industrial applications.

This bar chart illustrates the importance of different materials used in hydraulic pump components, showcasing their relative advantages and suitability for various industrial applications.

When selecting hydraulic pump parts for industrial applications, evaluating the reputation and experience of manufacturers is crucial. A manufacturer's standing in the industry often reflects their commitment to quality, innovation, and reliability. In today’s rapidly evolving landscape marked by Industry 4.0, understanding a manufacturer’s technological readiness can provide insights into their capacity for delivering advanced solutions. This includes the ability to integrate IoT capabilities and utilize data-driven decision-making processes that can enhance the efficiency of hydraulic systems.

Furthermore, the shift toward sustainable practices emphasizes the importance of selecting manufacturers who are not only experienced but also conscious of life cycle assessments and environmental impacts. As industries transition to more intelligent manufacturing systems, those who adopt Industry 4.0 technologies can leverage their knowledge to offer sustainable products that align with both regulatory standards and market expectations. Companies should prioritize partnerships with manufacturers that demonstrate a proactive approach in these areas, ensuring they choose hydraulic pump parts that support long-term operational efficiency and sustainability goals.

When it comes to selecting hydraulic pump parts, assessing the quality control processes during production is vital to ensure longevity and performance. A manufacturer that prioritizes stringent quality control will conduct thorough inspections at various stages of production, from raw material sourcing to final assembly. This guarantees that each component meets industry standards and can withstand the rigors of industrial applications.

Tip 1: Always ask for quality control certifications from suppliers. These documents not only showcase the manufacturer’s commitment to quality but also provide insight into their testing methods and standards.

Additionally, it's essential to consider the traceability of parts. Manufacturers should maintain detailed records of inspections and testing, so you know exactly how each component was handled throughout its production. This transparency reflects their dedication to maintaining high-quality standards.

Tip 2: Look for suppliers who offer warranties on their products. A warranty indicates confidence in their quality control measures and provides you with peace of mind regarding your investment.

By understanding and prioritizing these quality control processes, you can make informed decisions and ensure that the hydraulic pump parts you choose will fulfill your industrial needs effectively.

When selecting hydraulic pump parts, pricing and warranty options play a crucial role in the decision-making process, particularly for industrial needs. Different manufacturers offer a wide range of prices, and understanding the value behind these figures is essential. It's important to compare not only the upfront costs but also the long-term value of the components you are considering. Cheaper parts might save you money initially but could lead to higher replacement costs or downtime later on, so evaluating the overall cost-effectiveness is vital.

Moreover, warranty options can significantly influence your choice of hydraulic pump parts. A robust warranty reflects the manufacturer’s confidence in their product’s durability and performance. It's essential to look for warranties that cover a reasonable period and include comprehensive terms, as this can provide valuable peace of mind. When comparing manufacturers, take the time to read the warranty details and breakdowns, ensuring you understand what is included and any conditions that may apply. This diligence will not only help you in making a sound investment but also in avoiding potential pitfalls down the line.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy