- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

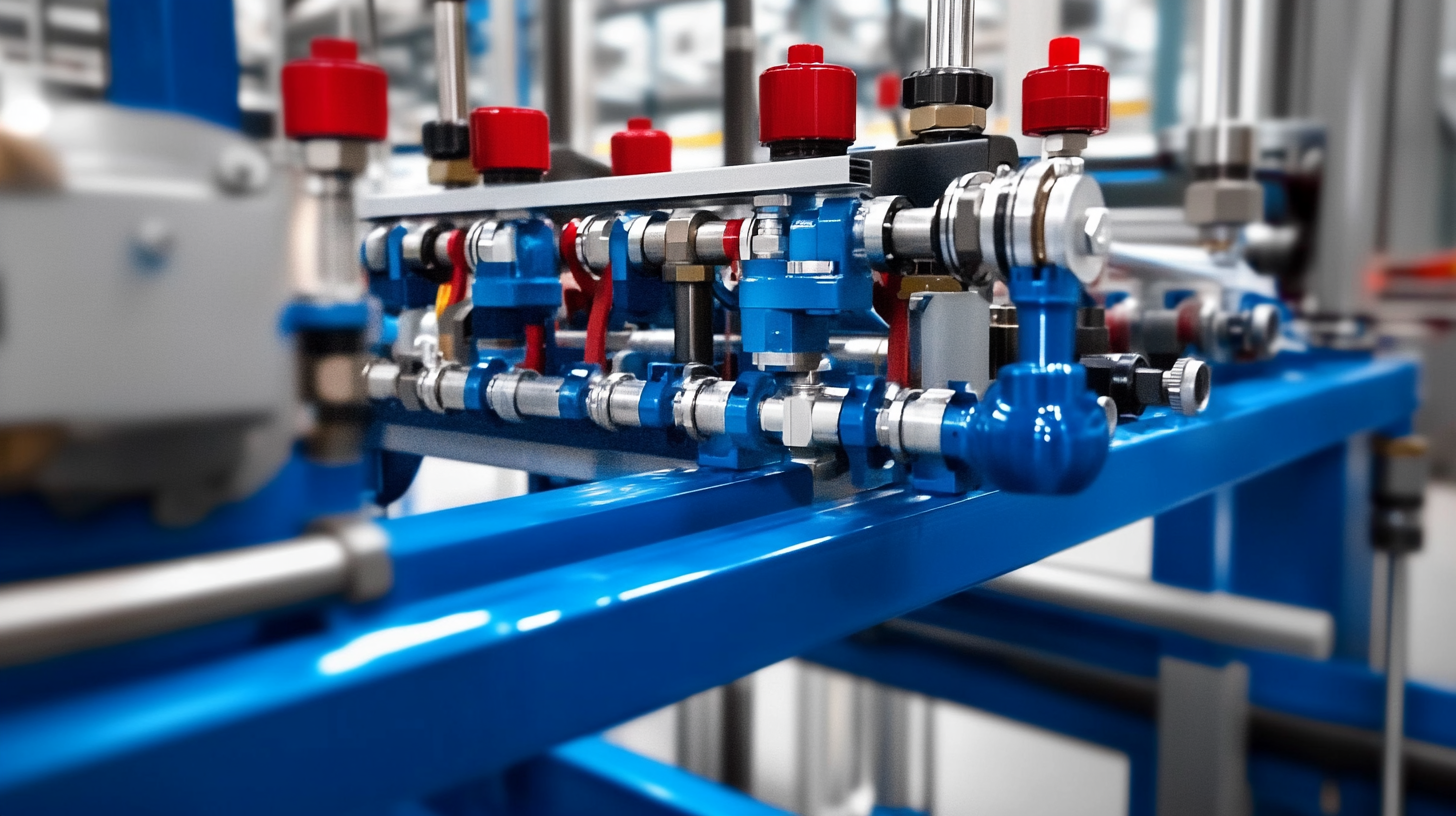

In the ever-evolving landscape of hydraulic systems, the selection of the right hydraulic flow divider has become crucial for businesses aiming to optimize efficiency and minimize downtime. According to a recent industry report, the global hydraulic flow divider market is projected to reach USD 1.2 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 5.2%. This growth underscores the increasing reliance on hydraulic flow dividers across various sectors, including manufacturing, construction, and agriculture. Choosing the best hydraulic flow divider tailored to specific operational needs can enhance performance, reduce energy consumption, and extend equipment lifespan. As businesses navigate this pivotal decision, understanding the nuances of hydraulic flow dividers becomes essential for achieving sustained operational excellence and competitive advantage in their respective industries.

When selecting a hydraulic flow divider, the importance of after-sales service cannot be overstated. A report by the International Journal of Fluid Power indicates that approximately 30% of operational failures in hydraulic systems are attributed to inadequate maintenance and support. This statistic underscores the necessity of securing a reliable after-sales service package from your supplier. Timely support can significantly reduce downtime and costly repairs, enhancing the overall efficiency of your operations.

When considering the financial aspects of hydraulic systems, particularly in the context of maintaining advanced hydraulic flow dividers, budgeting for repair costs is crucial. Reports suggest that maintenance costs for specialized equipment can be as much as four times higher compared to traditional systems. For instance, the budget allocation for maintenance in facilities like parks can soar, with cities like Kaohsiung estimating annual maintenance costs as high as 1.2 billion yuan. This stark difference emphasizes the need for comprehensive budgeting strategies.

In evaluating the total cost of ownership, businesses must not only assess the initial investment in hydraulic equipment but also anticipate ongoing maintenance expenses. Industry studies indicate that proactive maintenance can reduce unscheduled downtime by approximately 30%, ultimately leading to cost savings. As such, creating a "Park Management Fund," as seen in governance discussions in Kaohsiung, can significantly alleviate the financial burden on municipal budgets while ensuring hydraulic systems remain operational and efficient. Engaging with expert sources and data can greatly aid in making informed decisions that align with specific operational needs and financial constraints.

| Criteria | Description | Estimated Repair Costs (Annual) | Maintenance Frequency |

|---|---|---|---|

| Flow Rate | The volume of fluid that can be delivered per unit time. | $1,000 - $3,000 | Quarterly |

| Operating Pressure | Maximum pressure at which the system can operate efficiently. | $500 - $2,000 | Bi-Annually |

| Compatibility | Suitability with existing hydraulic components and systems. | $300 - $1,500 | Annually |

| Efficiency | How effectively the flow divider distributes fluid among outlets. | $800 - $2,500 | Quarterly |

| Size/Port Configuration | Dimensions and port arrangement suited for specific applications. | $600 - $1,800 | As Needed |

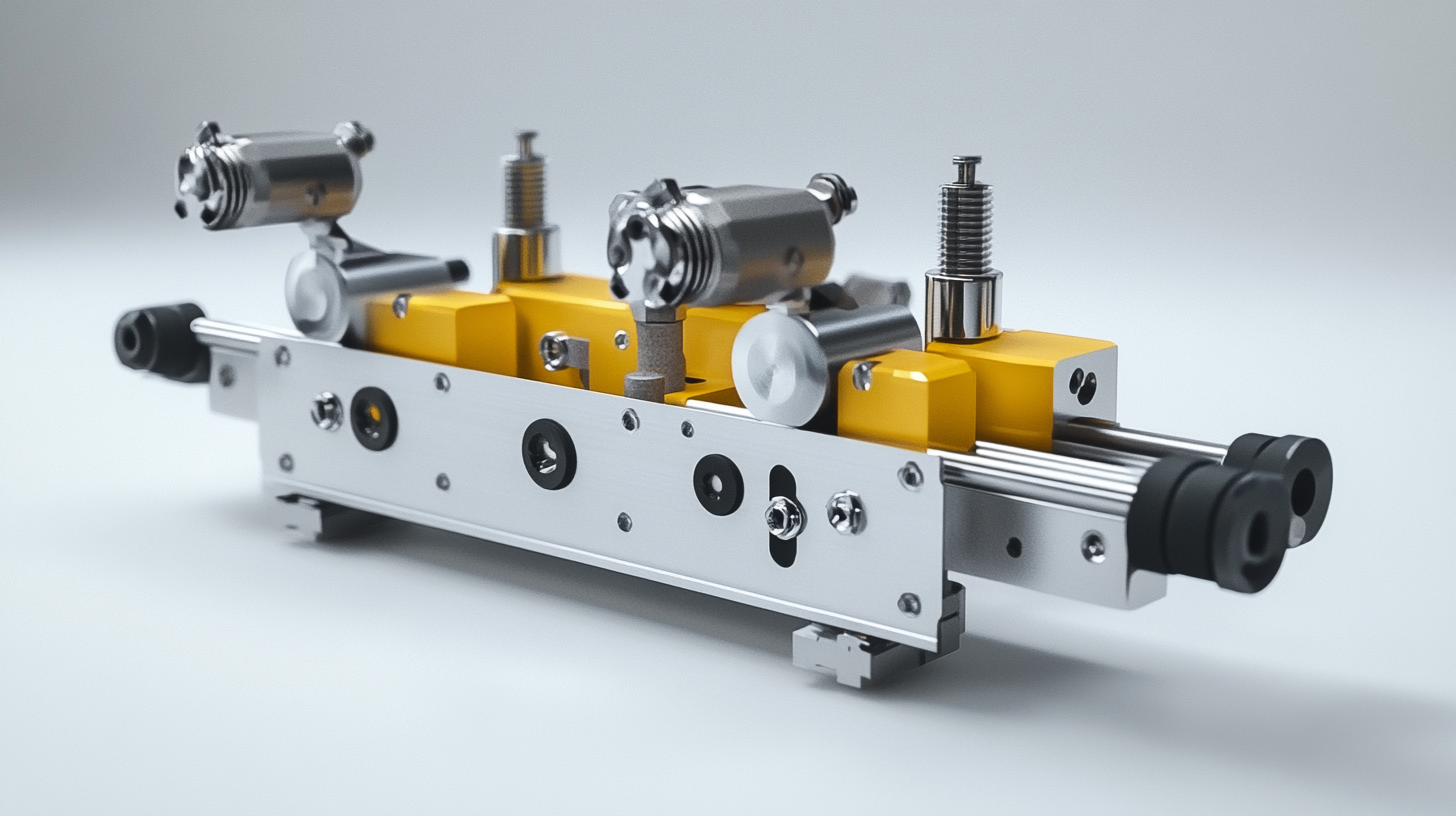

When selecting a hydraulic flow divider, it's crucial to focus on key features that will ensure optimal performance for your specific business needs. One of the most important aspects to consider is the flow split ratio; this determines how the hydraulic fluid is distributed among different circuits. A precise flow divider will enhance the efficiency of your system, ensuring that each section receives the correct amount of fluid, which can help in minimizing wear and tear on components.

When selecting a hydraulic flow divider, it's crucial to focus on key features that will ensure optimal performance for your specific business needs. One of the most important aspects to consider is the flow split ratio; this determines how the hydraulic fluid is distributed among different circuits. A precise flow divider will enhance the efficiency of your system, ensuring that each section receives the correct amount of fluid, which can help in minimizing wear and tear on components.

Another critical feature is the size and port configuration of the flow divider. Depending on the layout of your hydraulic system, having the right dimensions and ports can facilitate easier installation and maintenance. Additionally, consider the pressure rating and temperature tolerance of the unit. A flow divider that can handle higher pressures and temperatures will offer increased reliability and longevity. By evaluating these features, you can select a hydraulic flow divider that not only meets your immediate requirements but also supports the overall efficiency and durability of your hydraulic systems.

When selecting hydraulic equipment, understanding industry standards is crucial to ensuring reliability and efficiency in your operations. Industry standards serve as benchmarks for performance, safety, and compatibility. By choosing equipment that adheres to these standards, businesses can minimize the risk of equipment failure and maximize productivity. It’s important to familiarize yourself with standards such as ISO, SAE, and ANSI, which govern hydraulic systems.

Tips for selecting a reliable hydraulic flow divider include verifying certifications that meet industry standards. Ensure that your chosen equipment has been tested for safety under the applicable norms. Additionally, consider the manufacturer’s reputation; established brands often have a history of compliance and reliability.

Another tip is to evaluate the flow divider’s specifications against the requirements of your hydraulic system. This includes assessing flow rates, pressure ratings, and compatibility with other equipment. Customization might be necessary, so collaborating with manufacturers to tailor solutions based on your business’s specific needs can lead to more effective outcomes. Keeping these standards and tips in mind will greatly enhance your decision-making process when choosing hydraulic equipment.

When selecting a hydraulic flow divider, the quality of the unit can significantly influence your business's operational efficiency and downtime. High-quality flow dividers ensure optimal fluid distribution across multiple hydraulic circuits, enhancing system performance and minimizing the risk of leakage or failure. By allowing for precise control of fluid flow, superior products help maintain consistent pressure levels, which is crucial in applications requiring reliability, such as construction or manufacturing.

On the other hand, poorly constructed or subpar flow dividers can lead to increased downtime and maintenance costs. Defects in design or manufacturing processes may result in uneven flow distribution, causing certain components to operate inefficiently or even suffer damage over time. This not only affects productivity but can also compromise the safety of operators and equipment. Therefore, investing in high-quality hydraulic flow dividers is essential for businesses looking to enhance their operational efficiency and reduce equipment downtime effectively.

This chart represents the impact of hydraulic flow divider quality on operational efficiency and downtime. Higher quality flow dividers lead to lower downtime and increased productivity.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy