- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

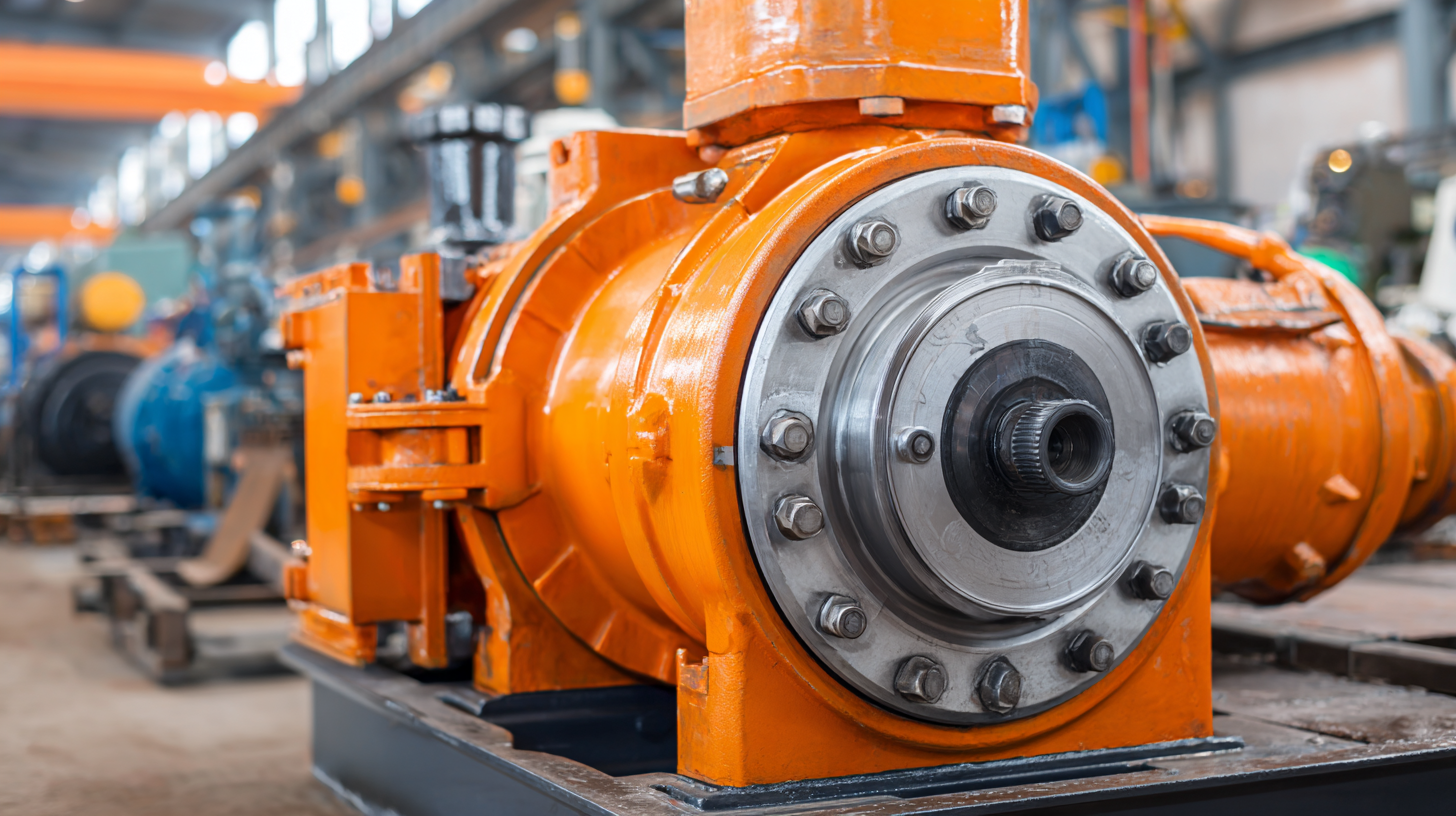

In the ever-evolving landscape of industrial machinery, the demand for reliable hydraulic pump repair services has surged significantly, driven by an expected growth rate of approximately 5.3% CAGR from 2021 to 2028 in the global hydraulic pump market, according to a recent market analysis report. As hydraulic systems form the backbone of numerous industries, from construction to manufacturing, the quality and efficiency of hydraulic pump repair services are paramount. Choosing the right manufacturer for these services not only ensures optimal performance and longevity of equipment but also prevents costly downtime that can severely impact productivity. With the increasing complexity of hydraulic systems and the rising emphasis on operational efficiency, understanding the nuances of hydraulic pump repair becomes essential for businesses looking to sustain competitive advantage in their respective sectors.

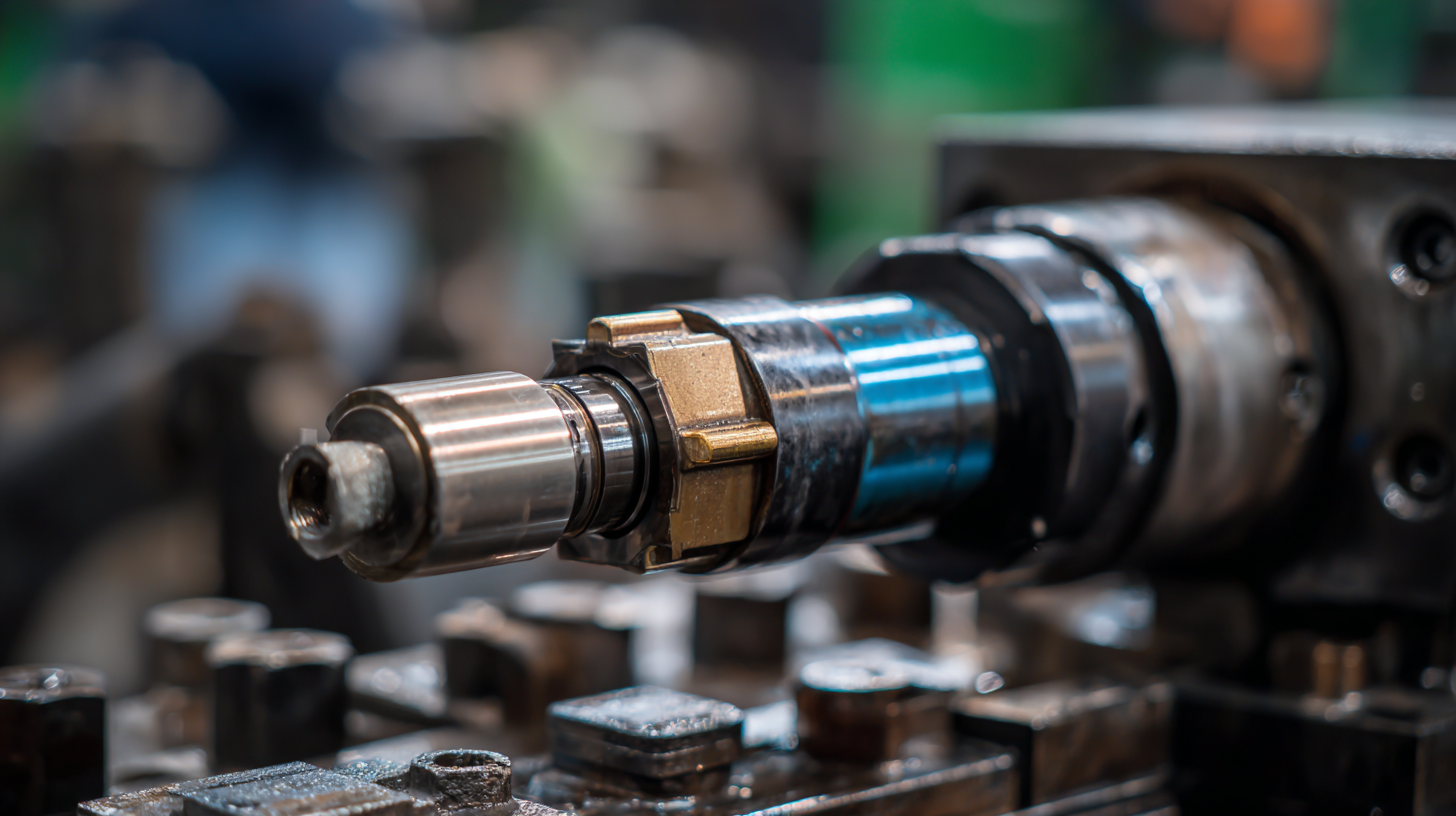

When it comes to hydraulic pump repairs, quality cannot be overstated. A well-functioning hydraulic pump is essential for the efficiency and reliability of machinery, and subpar repair services can lead to significant downtimes and costly malfunctions. Choosing a manufacturer that prioritizes quality ensures that every aspect of the repair process, from the selection of parts to the expertise of technicians, meets industry standards. This commitment to quality not only extends the lifespan of the hydraulic pump but also enhances overall operational performance.

Understanding the importance of quality in hydraulic pump repairs involves recognizing the potential risks associated with inferior services. A compromised repair can result in leaks, inconsistent pressure, and even complete system failures. It is vital to partner with manufacturers that employ rigorous quality control measures and utilize top-grade materials for repairs. Additionally, manufacturers with a proven track record of exceptional service and customer satisfaction are more likely to deliver reliable results. By prioritizing quality in hydraulic pump repairs, you safeguard your equipment's performance and ensure a superior return on investment.

When selecting a manufacturer for hydraulic pump repair services, several key factors can significantly influence the quality and efficiency of the service provided. First, assess the manufacturer's experience and expertise in the hydraulic industry. An established manufacturer with a proven track record can offer insights into complex repair solutions and ensure adherence to industry standards. Look for certifications and testimonials that validate their capabilities and highlight their commitment to quality.

Another critical factor is the availability of parts and technology. A manufacturer that uses high-quality components and advanced repair techniques can enhance the longevity and performance of repaired pumps. Additionally, consider their customer service and technical support. A responsive and knowledgeable team can make a difference, especially when unexpected issues arise during the repair process. Striking the right balance between these factors will help ensure that you choose a manufacturer who can meet your needs reliably, ultimately contributing to the smooth operation of your hydraulic systems.

In the rapidly evolving landscape of manufacturing, the role of technology in enhancing hydraulic pump repair services cannot be overstated. With the global helicopter MRO (Maintenance, Repair, and Overhaul) service market projected to grow from $40.79 billion in 2024 to $54.01 billion by 2032, at an annual growth rate of 3.6%, the integration of advanced technologies is pivotal. These innovations streamline repair processes, improve precision in diagnostics, and ultimately elevate the quality of services provided to clients.

As manufacturers increasingly embrace digital transformation, such as the recent recognition of Jiangxi Changxin Jinyangguang Electric Power Co., we see a shift towards smarter, more efficient repair methodologies. Utilizing AI and data analytics not only optimizes operational efficiency but also enhances customer satisfaction by addressing their diverse needs in the automotive aftermarket. For instance, the U.S. automotive repair and maintenance market is anticipated to grow by 10.1% from 2024 to 2032, emphasizing the industry's necessity for adopting cutting-edge technologies.

Tips:

1. When selecting a manufacturer for hydraulic pump repairs, prioritize those incorporating advanced diagnostic tools and predictive maintenance technologies.

2. Stay updated on market trends and technological advancements to ensure your chosen service provider remains competitive and effective in addressing your specific repair needs.

When selecting a manufacturer for hydraulic pump repair services,

customer feedback and

reputation play a critical role in ensuring you receive top-quality work.

Start by scouring online reviews and testimonials to get a grasp of other clients' experiences.

Look for consistent themes in feedback, such as communication quality, turnaround times, and the technical expertise displayed by the manufacturer.

A high volume of positive reviews can often indicate a reliable choice.

Tips:

Don’t hesitate to reach out to past customers for their insights.

A simple conversation can reveal invaluable information about the manufacturer’s strengths and weaknesses.

Additionally, you may want to check for any

certifications or

industry accreditations, which can further validate a manufacturer's reputation.

Furthermore, consider how long the manufacturer has been in the business and their track record with hydraulic repairs.

Longevity often hints at a stable operation with a solid client base.

Manufacturers who actively engage in industry forums or publish informative content demonstrate their commitment to keeping current with technological advancements, which can translate into better service for you.

Tips:

Look for manufacturers that offer

warranties on their repair services.

A robust warranty reflects confidence in their workmanship and gives you peace of mind should any issues arise post-repair.

When selecting a manufacturer for hydraulic pump repair services, ensuring compliance with industry standards is crucial for maintaining operational efficiency and safety. According to a report by the National Fluid Power Association (NFPA), nearly 50% of hydraulic system failures can be traced back to improper maintenance practices. This statistic underscores the importance of working with a manufacturer that adheres to recognized standards, such as ISO 9001, which focuses on quality management systems. By ensuring compliance with these standards, manufacturers not only enhance their service quality but also help prevent future system failures.

Furthermore, adherence to industry regulations, such as those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), plays a pivotal role in maintaining workplace safety during repair processes. A 2021 industry survey revealed that businesses that work with compliant manufacturers report 30% fewer workplace accidents related to hydraulic systems. Choosing a manufacturer that emphasizes these compliance measures not only protects the integrity of the hydraulic pumps but also fosters a safer work environment. Proper documentation and utilization of certified parts during repairs are essential steps in achieving these standards, ultimately leading to increased equipment longevity and reliability.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy