- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

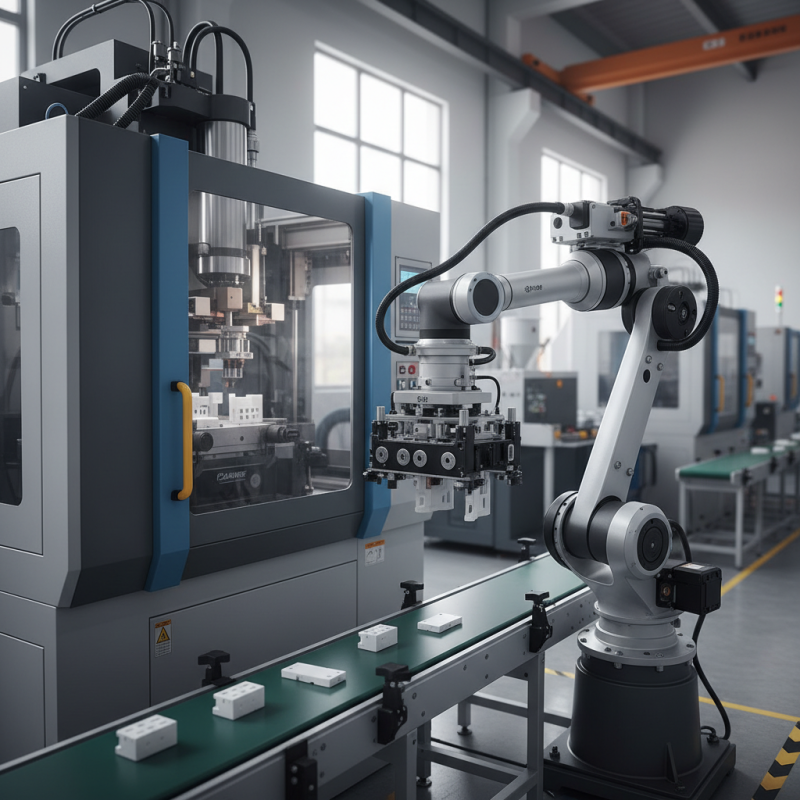

In today's fast-paced manufacturing environment, selecting the right Injection Molding Machine With Robot automation is crucial. Industry expert John Smith once stated, "Automation transforms efficiency, but it needs the right equipment." This highlights the importance of informed decisions in equipment selection.

When choosing an Injection Molding Machine With Robot, consider the specific needs of your production. Think about cycle times, precision, and material types. Not all machines will suit every project. For instance, a machine designed for thin-walled products may not perform well with thicker materials. It's vital to assess your production goals thoroughly.

Moreover, integrating a robot with your injection molding machine requires careful planning. An ill-suited robot can lead to workflow issues. Everyone dreams of seamless automation, but achieving it requires more than just buying the latest technology. Reflecting on these factors can lead to smarter choices and improved productivity.

When choosing an injection molding machine with robot automation, several factors are vital. Think about the production volume you expect. High volumes may require machines with faster cycle times. Evaluate the material types you will use as well. Different materials have different processing requirements. Ensure the machine can handle them effectively.

The integration of robotic automation is also crucial. Assess the complexity it adds to your process. While automation can improve efficiency, it may require significant adjustments. Pay attention to the layout of your factory too. A well-planned space reduces potential bottlenecks. Maintenance should not be overlooked either. An easily accessible machine makes troubleshooting simpler.

Consider your long-term goals. Are you planning to expand? A flexible machine could save costs later. However, remember that not every feature is essential. Prioritize what will benefit your production the most. Reflection on these factors can lead to a more informed decision.

When selecting an injection molding machine, understanding the different types is crucial. General-purpose machines are versatile. They serve a wide range of applications. These machines are cost-effective but may lack specialized features.

Specialized machines focus on particular materials or processes. For instance, if you're working with highly viscous polymers, consider a machine designed for that purpose. Smaller shops often choose all-electric machines. They are energy-efficient and require less maintenance, but their initial cost can be higher.

**Tips:** Evaluate your production needs. Think about the volume of parts required and material types. If your output is high, consider hybrid options. They combine hydraulic and electric systems for better efficiency. Always assess the machine's automation capabilities. Robotic integration can enhance productivity, but it might complicate setup. Careful planning will save time and costs in the long run.

Robot automation is transforming the injection molding industry. Recent studies show that factories implementing robotic systems can increase production efficiency by up to 30%. This means faster cycle times and reduced labor costs. With robots handling tasks like part removal and quality inspection, manufacturers can reallocate human resources to more complex functions.

Moreover, the accuracy of robotic automation is a game changer. A report from industry experts indicates that error rates can drop by 50% when robots are involved in repetitive tasks. However, integrating this technology isn't without challenges. There is still a learning curve, and companies may face resistance from their workforce. It's crucial to invest in training programs to ensure smooth transitions.

Additionally, not all injection molding processes benefit equally from automation. Some tasks may still require human supervision for optimal results. This underscores the need for careful analysis before choosing a robotic system. Companies must evaluate their specific production needs. Ignoring this step can lead to wasted resources and suboptimal performance.

When selecting an injection molding machine enhanced with robot automation, it's crucial to evaluate production capacity and efficiency requirements. According to recent industry research, a well-optimized facility can achieve cycle times as short as 15 seconds. Such efficiency boosts not only reduce costs but also increase output. However, relying solely on machine specifications can be misleading.

Understanding your production needs is essential. For example, if you require a monthly output of 1 million parts, a machine with a cycle time of 30 seconds may not suffice. It often leads manufacturers to underestimate the complexity of project timelines. Improper forecasting can cause bottlenecks, impacting deadlines. Robotics can alleviate this, but improper integration challenges arise. Industry studies indicate that automation increases overall output by 20-30%, but it requires meticulous planning.

Integrating robots with molding machines involves careful consideration of both initial investment and long-term gains. Reports have shown that a smart automation setup might require a 10-15% increase in upfront costs. Still, it yields a significant return on investment over time. Nevertheless, not every operation will see the same advantages. There must be clear alignment between the machine capabilities and actual production goals for maximum effectiveness.

When budgeting for injection molding machines with robot automation, it's essential to consider various factors. Start by assessing your overall production needs. Understanding your requirements helps narrow down the machine types suitable for your operations.

A common mistake is underestimating total costs. The initial price of a machine is only part of the expenses. Maintenance, materials, and energy consumption also matter. Ensure to include these in your budget.

Tips: Evaluate all operational costs related to machine usage. Look beyond the purchase price. Invest in energy-efficient models to save in the long run.

When integrating automation, consider potential labor savings. Robots can run continuously, reducing the need for manual labor during night shifts. However, the learning curve for staff might be longer than expected. Training should be factored into your budget.

Tips: Plan for comprehensive staff training. Allocate funds for unexpected operational hiccups. This forecasting prevents potential disruptions later on.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy