- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

In the rapidly evolving landscape of industrial machinery, the significance of Iron Pumps cannot be overstated. As global manufacturing preferences shift, a recent report by Mordor Intelligence highlights that the global pump market is expected to reach $103.3 billion by 2025, with iron pumps playing a crucial role in this growth. With advancements in technology and an increasing demand for energy-efficient solutions, the best Iron Pumps are now equipped with innovative features that enhance performance and reliability.

From enhanced corrosion resistance to optimized energy consumption, these pumps exemplify the cutting-edge of Chinese manufacturing prowess, which continues to lead the world in industrial pump production. Understanding these innovative features not only allows industries to make informed purchasing decisions but also underscores the potential of modern Iron Pumps to transform operational efficiencies.

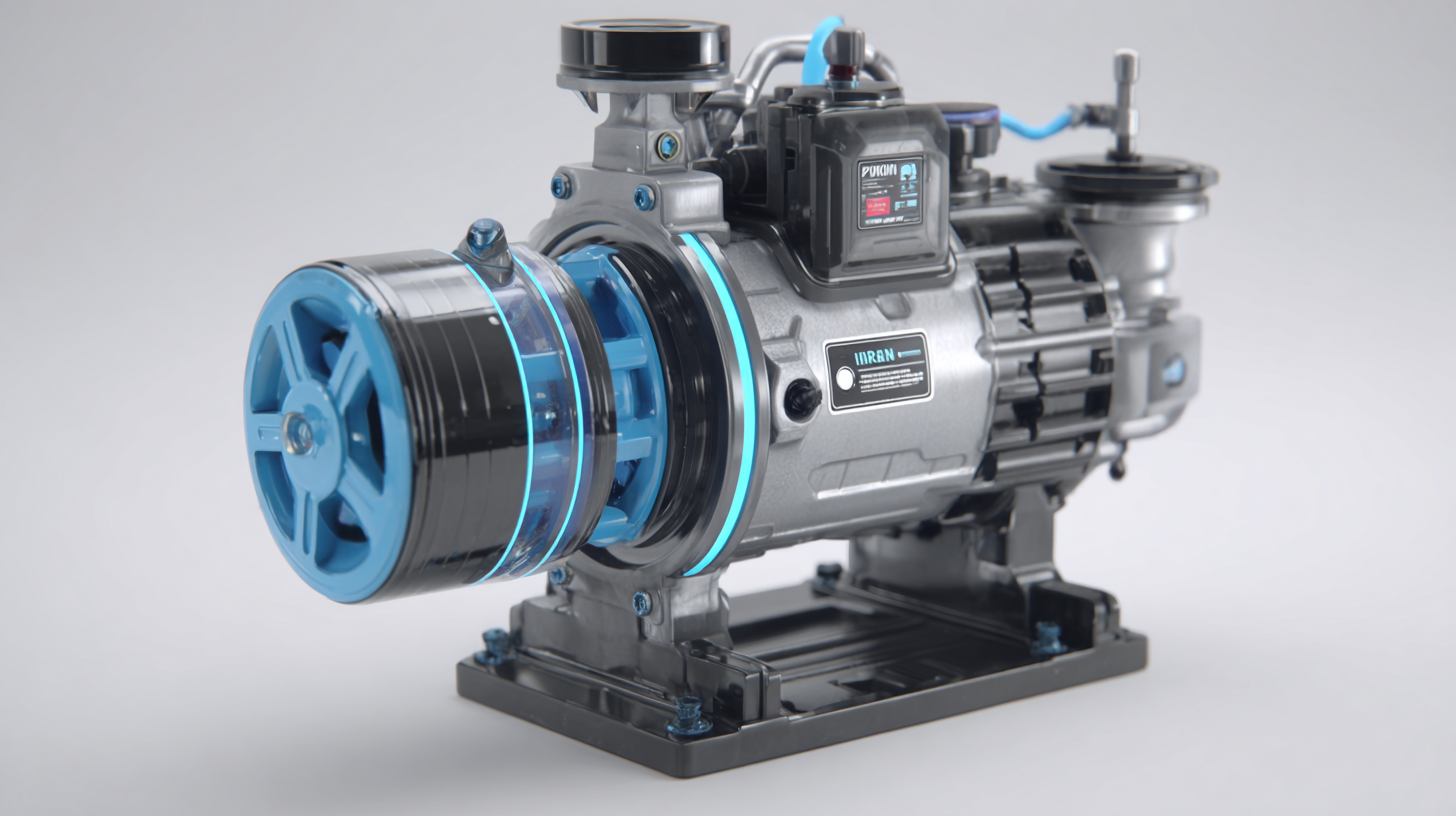

The emergence of smart iron pumps is revolutionizing industrial applications, offering unprecedented benefits in efficiency and reliability.

According to a recent report from MarketsandMarkets, the smart pumps market is projected to reach $18.62 billion by 2025, growing at a CAGR of 6.5%. This shift indicates a strong trend towards adopting advanced technology in fluid management systems.

Smart iron pumps leverage IoT connectivity, enabling real-time monitoring and predictive maintenance, which helps industries minimize downtime and optimize operational performance.

Smart iron pumps leverage IoT connectivity, enabling real-time monitoring and predictive maintenance, which helps industries minimize downtime and optimize operational performance.

Moreover, these innovative pumps are equipped with features like

automated flow control,

energy consumption tracking, and

remote operation capabilities.

A study by Grand View Research highlights that the adoption of smart pumps can reduce energy usage by up to 30% compared to traditional models.

This not only lowers operational costs but also contributes to sustainability efforts by decreasing the carbon footprint of industrial facilities.

As industries increasingly prioritize efficiency and environmental responsibility,

smart iron pumps are positioned as key players in the future of industrial fluid management.

The demand for energy efficiency in industrial operations has never been greater, and innovative iron pumps are stepping up to meet this challenge. These advanced pumps utilize cutting-edge technologies to significantly reduce energy consumption, leading to operational cost savings of up to 30%. By incorporating smart sensors and variable frequency drives, modern iron pumps optimize their performance based on real-time system demands, minimizing energy waste and enhancing overall productivity.

Additionally, the design of these pumps focuses on streamlined mechanics and advanced materials, which contribute to their efficiency. With features such as low-friction bearings and improved hydrodynamics, they can maintain high performance while using less energy. As companies seek to reduce their carbon footprint and operational expenses, investing in these innovative iron pumps not only supports sustainability goals but also improves the bottom line. Embracing the latest advancements in pump technology is becoming essential for businesses aiming to thrive in a competitive marketplace.

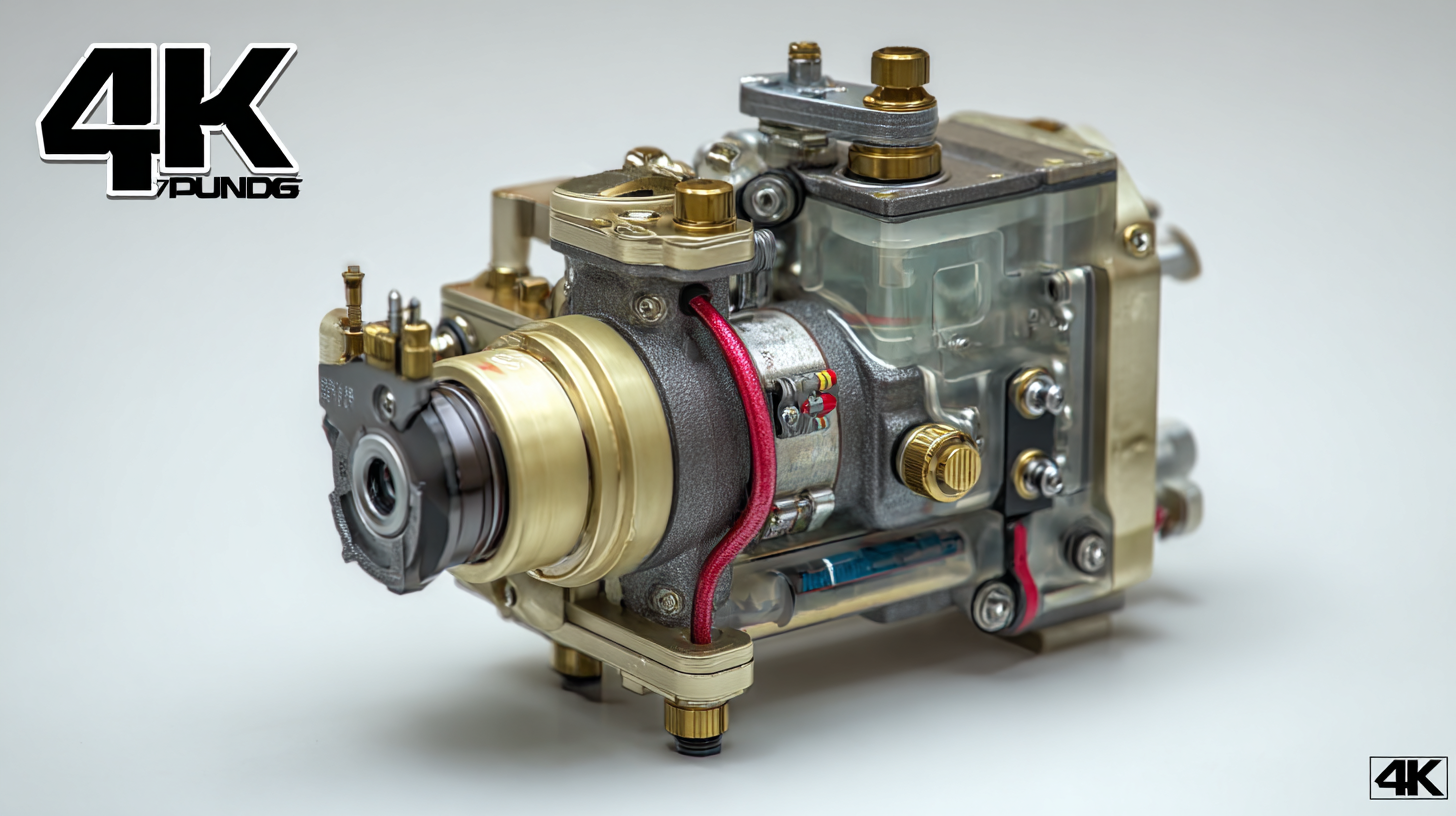

In the realm of iron pump design, advanced materials play a pivotal role in enhancing both durability and performance metrics. Traditional materials often fall short in withstanding the harsh operating conditions commonly encountered in industrial applications. However, the emergence of engineered alloys and composite materials has revolutionized the construction of iron pumps, allowing them to resist corrosion, wear, and fatigue more effectively. These innovative materials not only prolong the lifespan of the pumps but also ensure consistent operational efficiency, reducing downtime and maintenance costs.

Moreover, the integration of high-performance coatings has further contributed to the resilience of iron pumps. These coatings provide a protective barrier against abrasive particles and chemical exposure, thereby minimizing surface degradation. Alongside this, advancements in manufacturing processes, such as precision casting and 3D printing, allow for the creation of complex geometries that optimize fluid dynamics within the pump. This results in improved flow rates and energy efficiency, demonstrating how the choice of materials goes hand in hand with design innovations to enhance overall performance in iron pump technology.

In the era of smart technology, integrated IoT features in iron pumps are revolutionizing the way we monitor and manage performance. Real-time monitoring allows operators to track key metrics such as pressure, flow rate, and temperature from anywhere, enhancing responsiveness to potential issues. With data analytics, these systems can identify patterns and predict failures before they happen, significantly reducing downtime and maintenance costs.

When implementing IoT technology in your operations, consider the importance of data integration. Ensure that your pump's IoT platform can seamlessly connect with existing management systems, allowing for a cohesive overview of operations. Regularly training staff on these technologies is also crucial; fostering a culture of understanding will enable teams to leverage data effectively and make informed decisions.

Additionally, prioritize the security of your IoT infrastructure. As more devices connect to your network, vulnerability increases. Implement robust cybersecurity measures and conduct regular audits to safeguard sensitive operational data while enjoying the benefits of innovation. Leveraging these strategies can transform your pump management into a streamlined, efficient process that stands at the forefront of technological advancements.

As industries evolve, sustainability has become a crucial consideration in the development of iron pump technology. Modern iron pumps are increasingly designed with eco-friendly materials and energy-efficient mechanisms that not only meet but exceed industry standards. These advancements contribute to a reduced carbon footprint, showcasing a commitment to environmental responsibility. For instance, manufacturers are now utilizing innovative coatings and recyclable components that enhance longevity and decrease the need for replacements, further minimizing waste.

Moreover, many new iron pumps are engineered to optimize power consumption without compromising performance. By integrating smart technology, these pumps can monitor their operational efficiency and adapt to varying demand, significantly lowering energy use. This shift towards smarter, sustainable practices not only benefits the environment but also offers cost savings for businesses. As sectors focus on reducing their ecological impact, the integration of sustainability in iron pump technology represents a significant stride towards achieving a greener future.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy