- Our Products

- Repairs & Service

- Custom Design

- Blog

- About Us

- Resources

- Industries

- Contact Us

- Contact Bestrei UK

- Compliments / Complaints

- Global Supply

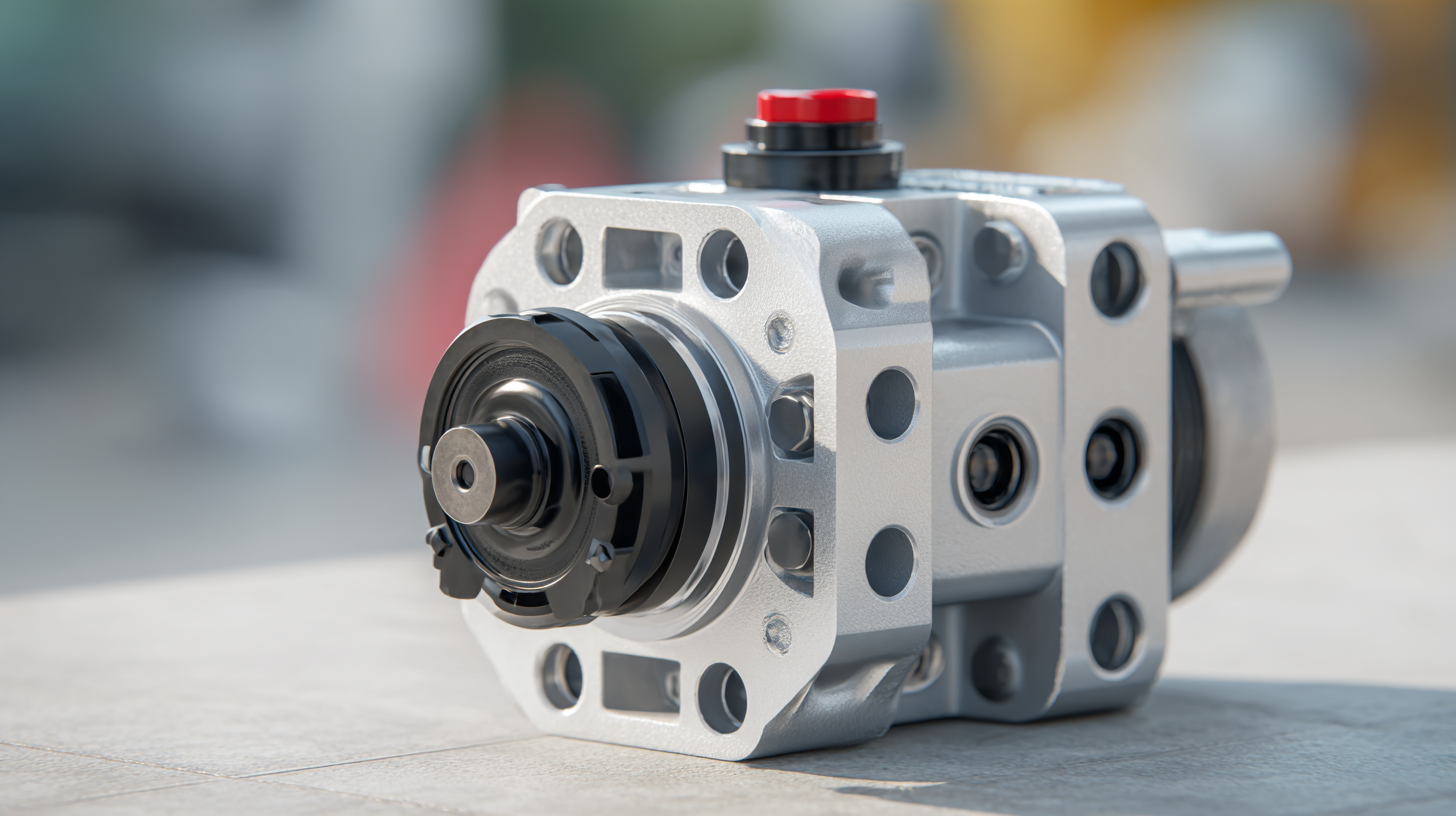

As we look ahead to 2025, the landscape of hydraulic technology is poised for remarkable evolution, particularly with the advent of advanced Hydraulic Gear Pumps. These essential components are set to revolutionize industries by enhancing efficiency, power output, and reliability in various applications.

With increasing demands for higher performance and sustainability, businesses are turning to cutting-edge hydraulic gear pumps that not only deliver superior fluid management but also integrate innovative design features for optimal functionality. From manufacturing to construction, the impact of these technological advancements will be far-reaching, enabling companies to operate at unprecedented levels of productivity while minimizing environmental impact.

This blog will explore the transformative trends influencing the development of hydraulic gear pumps, showcasing examples of how they are reshaping industry standards and driving forward the future of hydraulic systems.

As industries increasingly prioritize sustainability, hydraulic gear pumps are stepping up as key players in the drive for energy efficiency. The latest advancements in hydraulic technology have led to the development of high-performance gear pumps that maximize output while minimizing energy consumption. By integrating innovative design features such as improved sealing and optimized flow paths, these hydraulic systems reduce operational waste and enhance productivity, making them indispensable in sectors like manufacturing, construction, and agriculture.

Moreover, the growing awareness of environmental issues has prompted companies to adopt energy-efficient solutions, and hydraulic gear pumps fit the bill perfectly. With the ability to deliver precise control and responsiveness, these pumps not only reduce energy costs but also extend the lifespan of machinery by operating at optimal levels. As a result, industries can expect a significant decrease in their carbon footprint while benefiting from improved performance. The rise of these efficient hydraulic solutions signals a transformative shift towards greener operational practices, ensuring a sustainable future in various industrial applications.

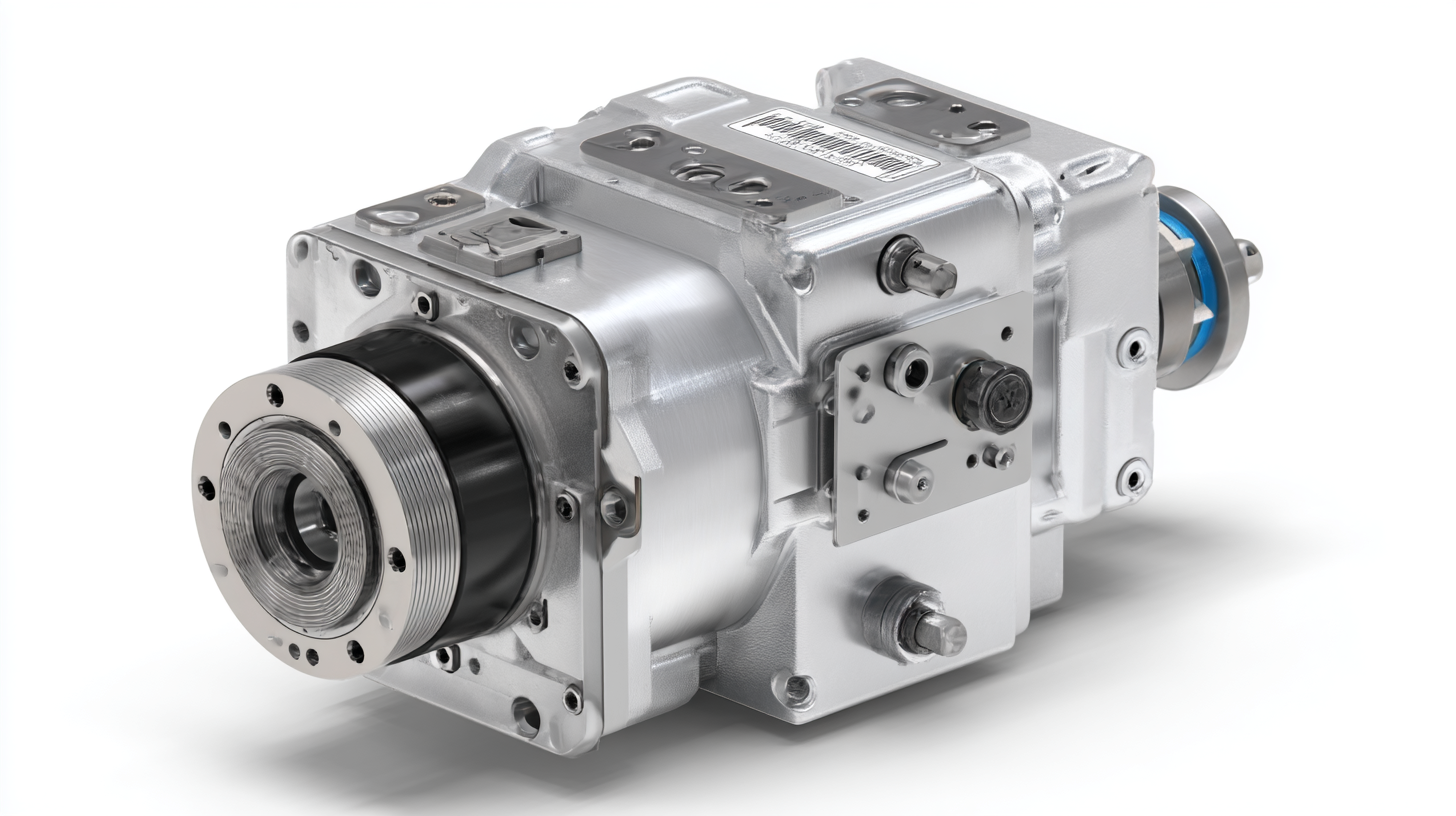

One of the most significant trends in hydraulic technology for 2025 is the emergence of advanced hydraulic gear pumps that prioritize innovative design features. The best hydraulic gear pumps are now integrating elements such as high-efficiency gear profiles, lightweight materials, and smart technology to enhance performance and durability. According to a recent market report by Allied Market Research, the hydraulic pumps market is expected to reach $18.2 billion by 2025, indicating a strong demand for these cutting-edge designs.

Tips: When choosing a hydraulic gear pump, look for models that incorporate variable displacement technology. This feature allows for seamless adjustments to flow rates, resulting in improved energy efficiency and reduced operational costs. Additionally, consider pumps built with composite materials that can withstand extreme conditions while minimizing weight, which contributes to easier installation and improved overall system performance.

Another standout design feature is the incorporation of IoT technology in hydraulic gear pumps. These smart pumps provide real-time data analytics for predictive maintenance, significantly reducing downtime. A report from Research and Markets indicates that predictive maintenance can save over 12% in operational costs, highlighting the importance of investing in innovative hydraulic solutions for future-ready industries.

The global industrial hydraulic equipment market is experiencing significant growth, projected to reach USD 52.6 billion by 2033, with a robust CAGR of 5.7%. After being valued at approximately USD 34.1 billion in 2023, this upward trajectory reflects increasing demand across various sectors, including construction, agriculture, and manufacturing. As industries continue to rely on hydraulic technology, innovations in hydraulic gear pumps are expected to play a pivotal role in enhancing operational efficiency and productivity.

Moreover, the hydraulic fracturing industry also shows promising growth, with projections estimating a rise from USD 47.9 billion in 2024 to USD 69.6 billion by 2030, at a CAGR of 6.4%. The expansion of this market underscores the crucial role that advanced hydraulic technologies will play in energy extraction and production processes. As these trends unfold, stakeholders in the hydraulic sector must remain attentive to the evolving market dynamics, ensuring they adapt and innovate to leverage new opportunities for growth and sustainability.

As industries evolve, the push towards sustainability has become a pivotal focus, significantly shaping the design and functionality of hydraulic gear pumps. According to a recent market report by Research and Markets, the global hydraulic pumps market is projected to reach $21.3 billion by 2025, driven largely by innovations aimed at reducing environmental impact. Manufacturers are increasingly adopting eco-friendly materials and technologies that minimize energy consumption, highlighting the importance of hydraulic gear pumps adapted to meet stringent environmental standards.

One emerging trend is the integration of smart technology into hydraulic systems. By utilizing IoT-enabled sensors, companies can optimize pump performance in real-time, resulting in higher efficiency and reduced waste. For instance, the Hydraulic Institute's report indicates that systems optimized with smart technology can reduce energy consumption by up to 30%. Additionally, manufacturers are emphasizing the use of biodegradable hydraulic fluids, significantly lowering the risk of environmental contamination. As these sustainable practices become mainstream, hydraulic gear pumps are not only evolving but also leading the charge towards a greener future in numerous industries, from agriculture to construction.

One emerging trend is the integration of smart technology into hydraulic systems. By utilizing IoT-enabled sensors, companies can optimize pump performance in real-time, resulting in higher efficiency and reduced waste. For instance, the Hydraulic Institute's report indicates that systems optimized with smart technology can reduce energy consumption by up to 30%. Additionally, manufacturers are emphasizing the use of biodegradable hydraulic fluids, significantly lowering the risk of environmental contamination. As these sustainable practices become mainstream, hydraulic gear pumps are not only evolving but also leading the charge towards a greener future in numerous industries, from agriculture to construction.

The integration of advanced hydraulic gear pumps is reshaping several key sectors, as evidenced by a range of successful implementations. In the construction industry, the usage of high-efficiency hydraulic gear pumps has been linked to a 15% increase in machine productivity, as reported by the Hydraulic Institute's 2022 Annual Report. By enabling better fluid power management, these pumps significantly reduce energy consumption while enhancing operational reliability. A notable case is the deployment of advanced pumps in excavators, which resulted in smoother operation and lower downtime, ultimately leading to cost savings that can exceed $100,000 annually per machine.

In the agriculture sector, precision farming is being propelled by sophisticated hydraulic systems. According to a recent joint study by AgriTech Insights, farms utilizing modern hydraulic gear pumps have experienced up to a 20% increase in yield, as these systems allow for more accurate control of planting and irrigation processes. One case study highlighted the successful implementation of hydraulic gear pumps in automatic seeders, where farmers managed to reduce water usage by 30%, thereby contributing to both environmental sustainability and economic viability. These examples illustrate not just the versatility of hydraulic technology, but also its critical role in driving efficiency across industries in 2025.

Bestrei UK has a strong footprint across Europe

United Kingdom, Ireland, France, Germany, Norway, Finland Sweden, Spain, Italy